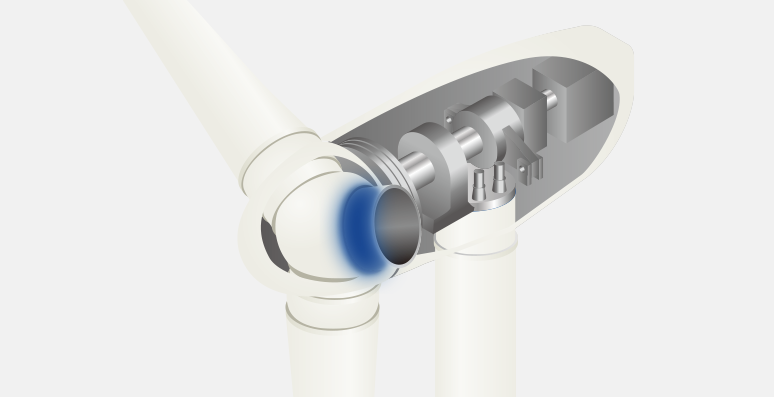

High precision machining of large bearings

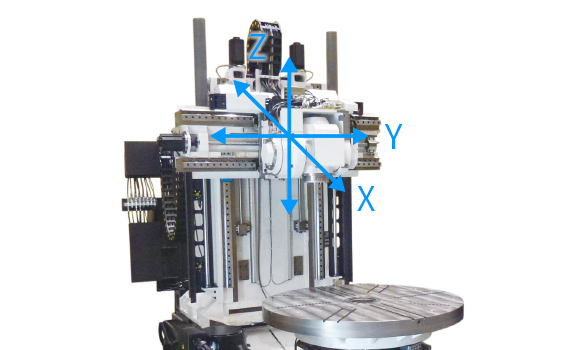

Y-axis machining of eccentric grooves

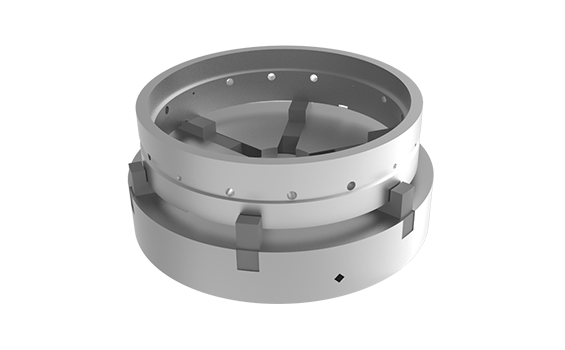

POINT 01

- Minimizing chucking distortion in large-diameter, thin-walled components using a special chuck

-

- Proposing a chucking method to achieve required accuracy based on our extensive experience

POINT 02

- Highly efficient machining of eccentric grooves using the Y-axis

-

- Eccentric bearing grooving can also be performed

using the Y-axis - Axis travel distance (X, Y, Z): 1,270 mm, 1,000 mm, 1,080 mm

- Rapid traverse rates (X, Y, Z): 32 m/min

- Eccentric bearing grooving can also be performed