High productivity is achieved through process-intensive machining and simple-to-operate space-saving robots

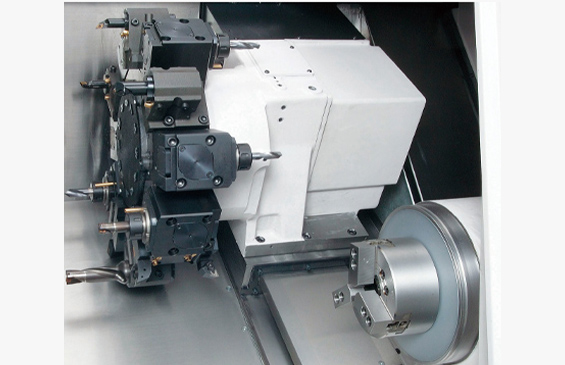

POINT 01

- The number of setups and workpiece transportations between processes are reduced through process-intensive machining

-

- A sub-spindle is used to complete process 1 and 2 on one machine.

- The number of setups and workpiece transportations between processes are minimized to reduce labor and chucking errors.

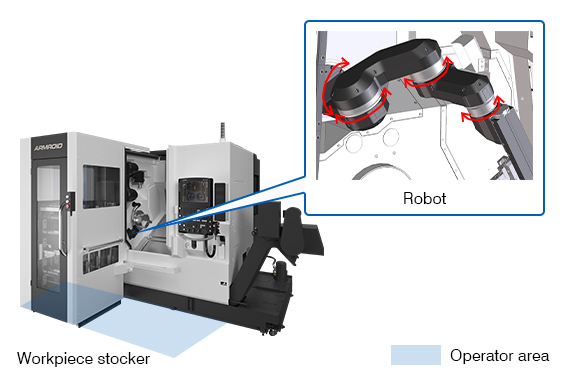

POINT 02

- Space-saving automation is achieved by combining a machine tool with a built-in robot

-

- Robot installed in the machining chamber automates loading and unloading of parts.

- A movable workpiece stocker is installed in the front of the machine.

- The stocker fits within the operator area, enabling automation to be done in the same space as when the robot is not used.

POINT 03

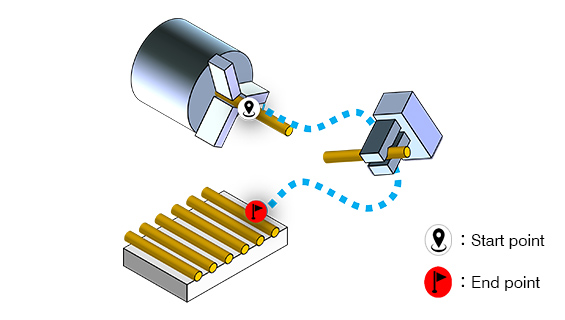

- Robot operation is easy even for operators who do not have experience with working with robots

-

- By simply teaching the start an end points, the NC automatically generates a collision-free path.

- The robot can be easily operated using the machine tool's pulse handle.