- HOME

- Okuma Technology Premium Solutions

- Grinder Setup Time-Saver Package

Okuma Technology Premium Solutions

Packaged functions useful for shaft grinding!

For highly accurate dimensional control of all outside diameters and dramatic reduction of setup change times.

More efficient shaft applications with Okuma's uniquely packaged grinding solutions

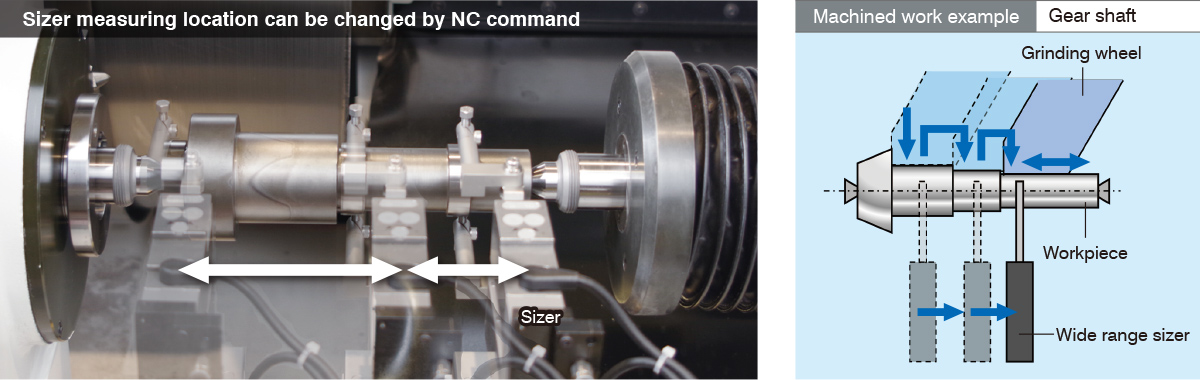

Achieving dimensional control of multi-step outside diameters

By NC positioning the wide range sizer, the measuring positions and diameters can be automatically changed by the program.

Providing setup time savings and highly accurate machining of multi-step OD parts.

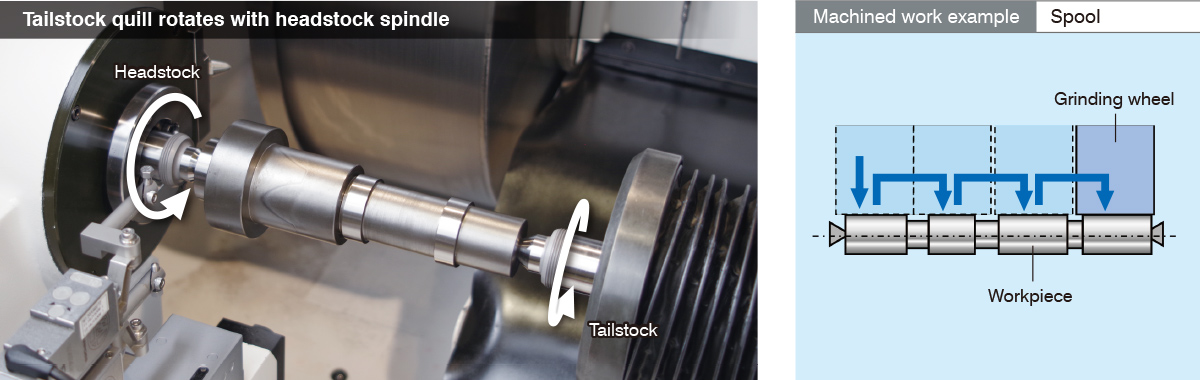

Achieving all OD grinding in one chucking

A chucking jig is not required because the center hole friction drive is dual-center driven from the headstock and tailstock.

Since driver setup changes aren't required, and all ODs can be ground without a part flip, setup time savings and process-intensive grinding are possible.

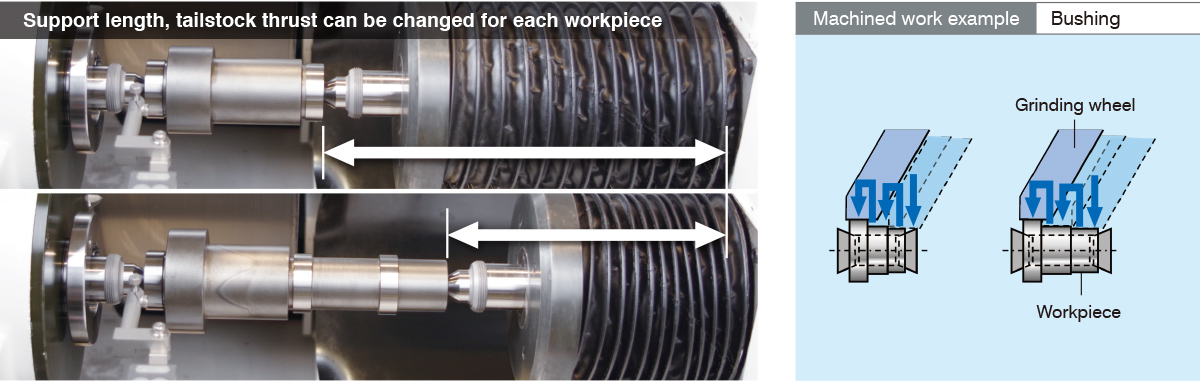

Workpieces of different lengths can be supported with no setup change

Workpiece support length and thrust can be automatically changed with the programmable NC tailstock.

Movement of the tailstock itself and thrust adjustment due to differences in workpiece length are no longer needed, and reduced setup time can be achieved.

Package content

Dual-center drive specifications

-

- Tailstock quill travel

- 170 mm (any setting with NC)

-

- Tailstock thrust

- 500 to 5,000 N (any setting with NC)

-

- Workpiece speed

- MAX 1,000 min-1

NC tooling base + wide range sizer

-

- Sizing travel range

- Full workpiece length (any setting with NC)

-

- Sizing diameter

- Max workpiece diameter w/o notch ø40 mm

Max workpiece diameter w/ notch ø25 mm

Compatible models

GP25W, GP26W, GA25W, GA26W (distance between centers 400, 650 mm)

Note: In some cases limitations occur in the workpieces that can be measured and ground.