- HOME

- Intelligent Technology

- SERVONAVI

Intelligent Technology

Achieves long-term accuracy and surface quality

Machining accuracy and surface quality are improved with automatic optimization of servo control. It can also immediately eliminate the reversal spikes, noise, vibration, crease marks, and “fish scales” that occur with long machine use over many years, maintaining long-term accuracy and stable movements.

-

Optimum settings automatically identified

SERVONAVI AI

(Automatic Identification)For machining centers

Shorter cycle times with faster acceleration Work Weight Auto Setting

For lathes

Achieves higher accuracy and more suitable movement Auto Inertia Setting

-

Enables longer machine use

SERVONAVI SF

(Surface Fine-tuning)Maintains machining accuracy and surface quality Reversal Spike Auto Adjustment

Contributes to longer machine life Vibration Auto Adjustment

Optimum settings automatically identified

SERVONAVI AI

(Automatic Identification)

Settings and motions

- Axes other than the measured one are retracted (interference prevention)

- Work Weight/Inertia Auto Setting is started

- Axis to be measured moves

- Parameter settings based on work weight and inertia is completed

- Machining start

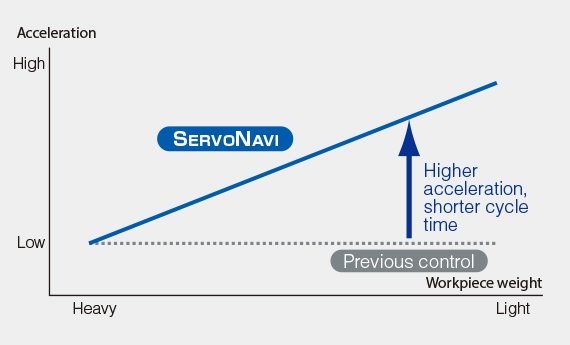

For machining centers

Work Weight Auto Setting

On table travel type machining centers, the table feed acceleration with the previous system was the same regardless of weight, such as workpieces and fixtures loaded on the table.

Work Weight Auto Setting estimates the weight of the workpiece and fixture on the table and automatically sets servo parameters, including acceleration, to the optimum values. Cycle times are shortened with no changes to machining accuracy.

Comparison of press die finishing times

- Cycle time reduced 12%

- Previous: About 13 h

- SERVONAVI: About 11.5 h

Simulated comparison.

Especially beneficial for dies requiring sculptured surface shaping.

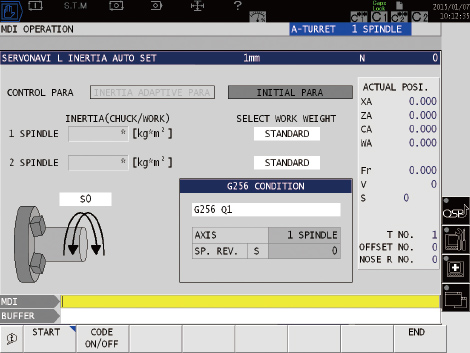

For turning centers

Auto Inertia Setting

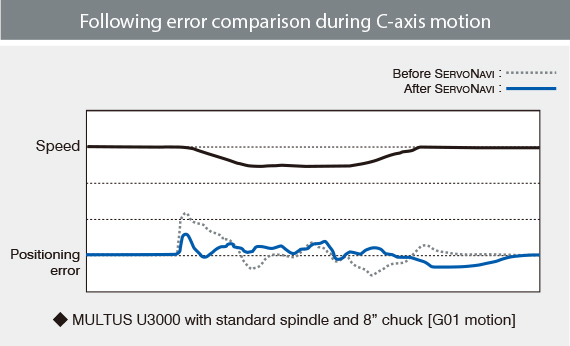

When chucks or workpieces are changed, inertia (inertial mass) also changes, sometimes resulting in greater positioning error.

Auto Inertia Setting estimates chuck and workpiece inertia from acceleration torque and automatically changes servo parameter settings to the optimum values so that high accuracy and stable movement can be maintained.

Enables longer machine use

SERVONAVI SF

(Surface Fine-tuning)

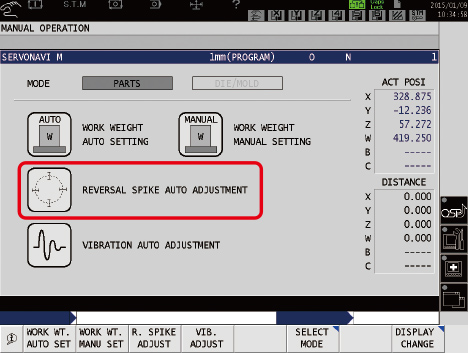

Settings and motions

- Axes other than the travel axis being adjusted are retracted (interference prevention)

- Reversal Spike Auto Adjustment—ON

- Linear and circular motion of travel axis being adjusted

- Adjustment completed

- Machining start

Making adjustments during regular maintenance checks is recommended.

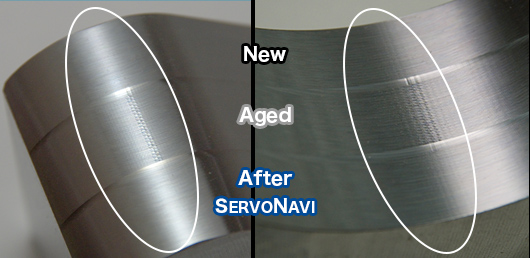

Reversal Spike Auto Adjustment

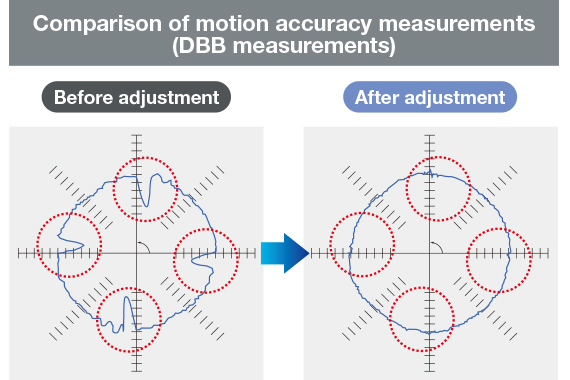

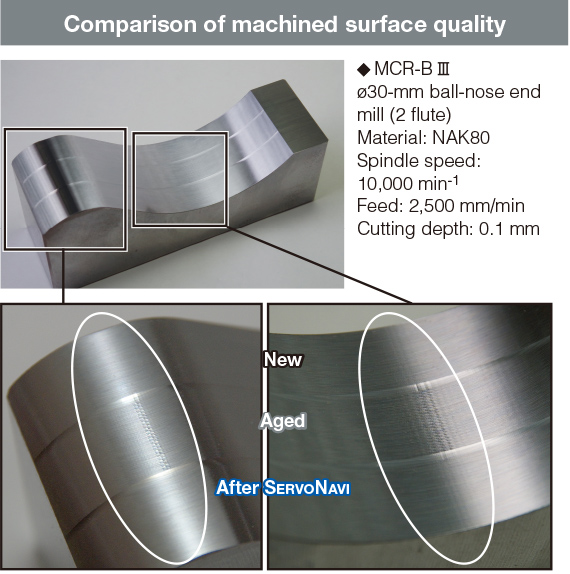

Slide resistance changes with length of time machine tools are utilized, and discrepancies occur with the servo parameters that were the best when the machine was first installed. This may produce crease marks at motion reversals and affect machining accuracy (part surface quality).

For example, when cutting a curved surface as shown below, there are creases from excess material when slide resistance is large and undercuts from removal of too much material when slide resistance is small. Both sometimes appear as a result of axis reversal spikes.

SERVONAVI's Reversal Spike Auto Adjustment maintains machining accuracy by switching servo parameters to the optimum values matched to changes in slide resistance.

Okuma's AbsoScale offers considerable improvement of machining accuracy and surface quality.

Without an AbsoScale, backlash compensation should be done when required.

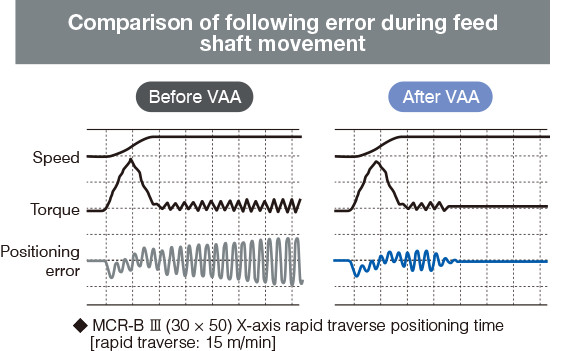

Vibration Auto Adjustment

When aging changes machine performance, noise, vibration, crease marks, or fish scales may appear. Vibration Auto Adjustment can quickly eliminate noise and vibration even from machines with years of operation.

Machine life is also lengthened since the ball screw replacement cycle can be increased.