- HOME

- Intelligent Technology

- 5-Axis Auto Tuning System

Intelligent Technology

- Higher levels of accuracy in 5-axis machining

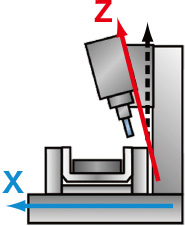

- In 5-axis machining accuracy, there are 13 types of “geometric error,” such as misalignment of a rotary axis, that greatly affect machining accuracy.

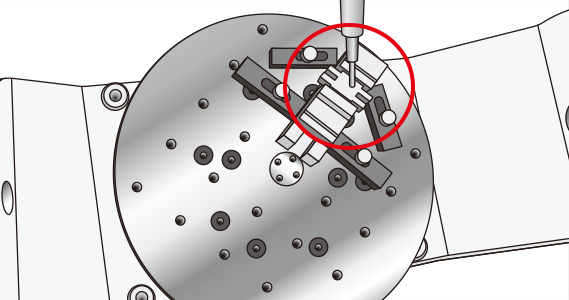

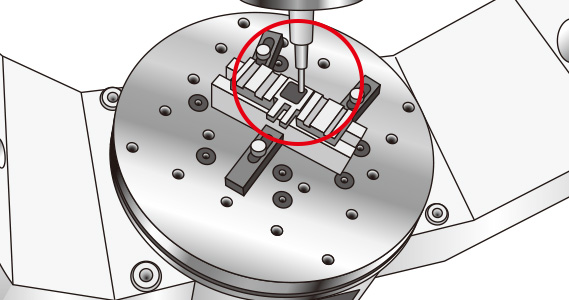

The 5-Axis Auto Tuning System measures geometric error using a touch probe and datum sphere. Tuning is done for motion accuracy of 5-axis machines by compensation using measurement results. This makes it possible for everybody to achieve 5-axis machining accuracies at higher levels.

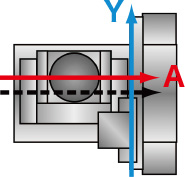

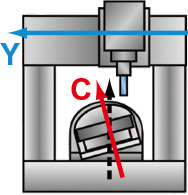

Examples of geometric error

-

A-axis misalignment in

Y-axis direction -

Perpendicularity error on

C and Y axes -

Perpendicularity error on

Z and X axes

- 5-Axis Auto Tuning System—Actual Examples

- 5-Axis Auto Tuning in multi-sided machining with tools (table) tilted at different angles for each surface significantly reduces boundary error in the machined surfaces.

Machined surface step error after manual adjustments done

without 5-AATS

Max 12 μm

Machined surface step error after using 5-AATS

Max 3 μm

(Actual data with MU-6300V)

Note: The data shown are actual data but do not represent guaranteed accuracies.

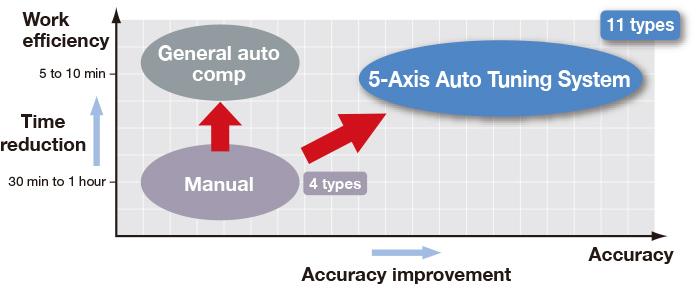

Quick and easy tuning by anyone

Let the machine do the tuning for you in about 10 minutes.*

Surprisingly simple with “Easy Operation” OSP.

*Measurement time when tuning for 11 types of geometric error in “Full” mode with MU-V series machines.

Measurement time changes depending on the machine type and measurement mode.

In “Simple” mode, tuning for 4 types of geometric error takes about 5 minutes.

- Takes 5-axis machining accuracy to next level

- Tuning of up to 11 types of geometric error

- Manual tuning has been a bothersome and time-consuming task, and so the geometric error for which tuning could be done was limited to only 4 types of center position error of the spindle axis. Moreover, while the working time could be shortened with general automatic tuning functions, the accuracy remained at the level achieved with manual work.

With the 5-Axis Auto Tuning System, the machine automatically tunes the machine for up to 11 types* of geometric error.

*With 5-Axis Auto Tuning System for multitasking machines, the maximum is 10 types.

- High-accuracy 5-axis machining maintained over long periods

- Even machines with little geometric error at the time of delivery are affected by changes in the floor and other factors over the long term, and geometric error becomes larger. The accuracy of 5-axis machines is also affected by changes in temperature and other factors.

Okuma's 5-axis machines maintain high-accuracy 5-axis machining over long-term operation with synergistic effects from the 5-Axis Auto Tuning System, which maximizes machining accuracy, and the Thermo-Friendly Concept that maintains high accuracy.

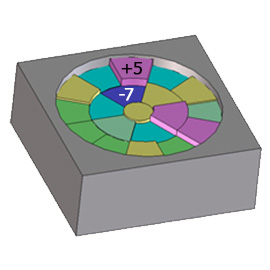

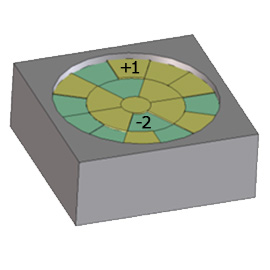

- Also effective for the periphery of large workpieces

- The effect of geometric error tends to be large on the periphery of 5-axis machining center tables.

In this case, the 5-Axis Auto Tuning System is highly effective.

-

Near table center

Conventional methods

(4 types of geometric error)Machining surface error

12 μm

After using 5-AATS

(11 types of geometric error)Machining surface error

3 μm

(MU-6300V actual data) -

-

Near table periphery

Conventional methods

(4 types of geometric error)Machining surface error

15 μm

After using 5-AATS

(11 types of geometric error)Machining surface error

6 μm

(MU-6300V actual data)Note: The data shown are actual data but do not represent guaranteed accuracies.

-