- HOME

- Intelligent Technology

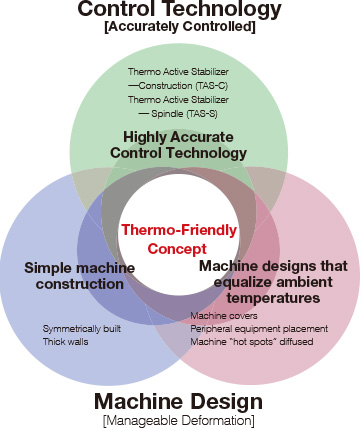

- Thermo-Friendly Concept

Intelligent Technology

- For superb accuracies in “normal” manufacturing environments

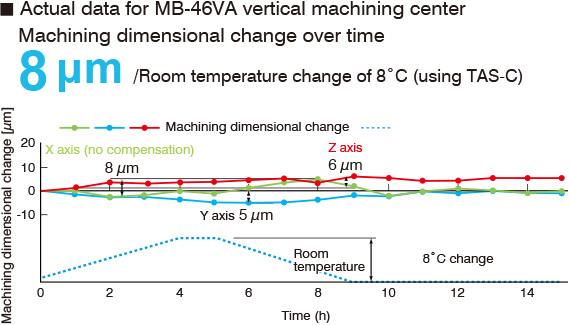

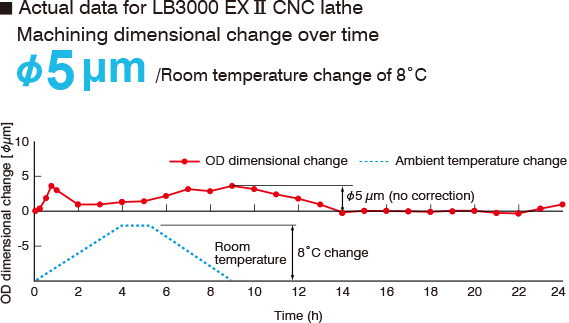

- Machining accuracy of the workpiece changes significantly due to ambient temperatures around the machine, heat generated by the machine, and heat generated in machining. The Thermo-Friendly Concept is the unique concept of “accepting” these temperature changes so that high accuracy can be achieved in normal factory environments with no special measures by the user.

-

-

Note: The data shown are actual data but do not represent guaranteed accuracies.

- Benefits

-

-

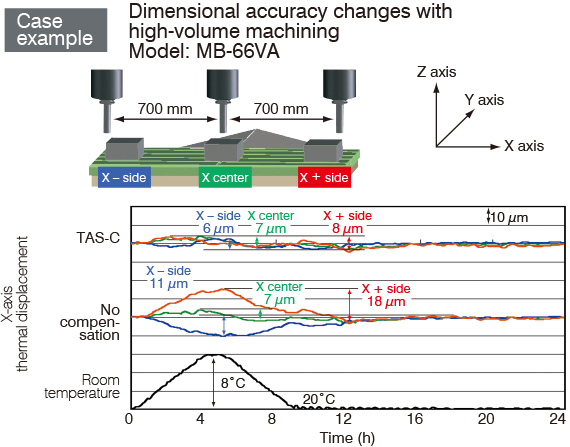

- Dimensional accuracy improved with high-volume machining

- By combining thermal deformation control with machining position, workpiece dimensional accuracy is improved even when a large number of workpieces are loaded.

Note: The data shown are actual data but do not represent guaranteed accuracies.

-

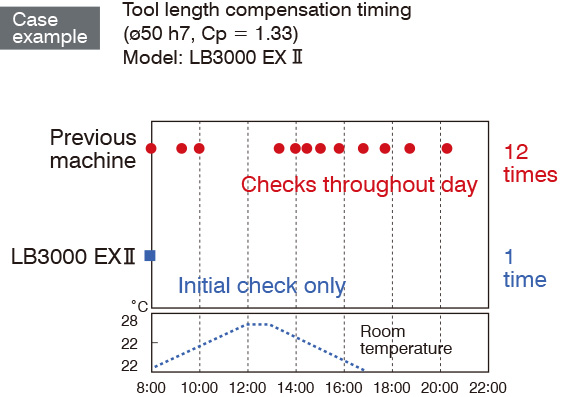

- Fewer tool compensation checks

- “Superb dimensional stability” means fewer compensation checks are required after the initial morning setup, regardless of shop temperature changes or afternoon/evening stoppages.

-

Integrated machine design and control technology

The Thermo-Friendly Concept plays a principal role in our machine design. With simple machine designs and construction that equalize ambient temperatures, deformation is predictable, and complex torsion or tilting is controlled.

Moreover, Highly Accurate Compensation Technology (Okuma control [OSP] award winning innovation) effectively responds to deformation caused by changes in room temperature, frequent spindle speed changes, and non-coolant cutting.

With the Thermo-Friendly Concept (Manageable Deformation—Accurately Controlled), Okuma products provide unrivaled dimensional stability.

- Simplified machine construction /

Machine design that equalizes ambient temperature - “Manageable deformation” —structural designing for controlled machine expansion/contraction (predictable directions), with heat transmitted evenly.

-

-

- Thermally symmetric structure

- The key to manageable deformation control

-

- Box-build structure

- Simple double-column structure for manageable thermal deformation

-

- Thermally balanced structure

- Placement of front cover and back control cabinet allow for even conduction of heat

[Thermo-Friendly]

Extremely accurate deformation control

-

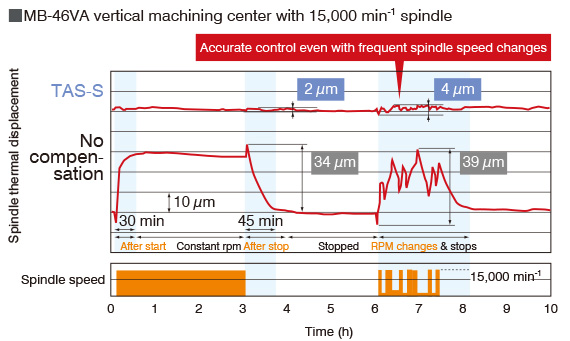

- Thermo Active Stabilizer — Spindle (TAS-S)

- Thermal deformation of the spindle changes greatly both when the spindle is turning and when it is stopped, affecting machining accuracy.

TAS-S considers not only spindle temperature information but also spindle rotation, spindle speed changes, and spindle stoppage. Thermal deformation of the spindle is accurately controlled even when spindle speed changes frequently.

Note: The data shown are actual data but do not represent guaranteed accuracies.

-

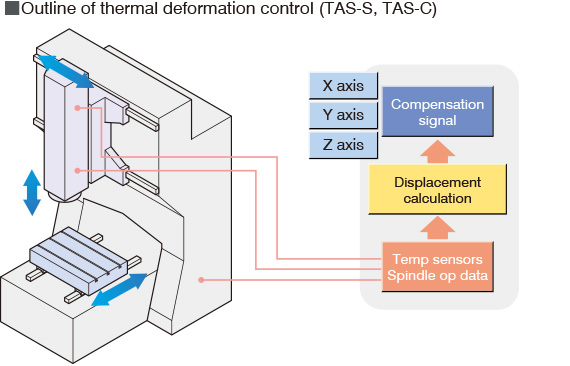

- Thermo Active Stabilizer — Construction (TAS-C)

- When machining under changing ambient temperatures, machining dimensional changes are affected by expanding/contracting machine components as well as workpiece position with respect to the table in machining centers and workpiece size in lathes.

TAS-C, based on machine thermal characteristics, with appropriately placed temperature sensors and feed axis position data, will predict and accurately control thermal deformation in machine construction when ambient temperatures change.

Thermo-Friendly Concept Applicable Models

| CNC Lathes |

|---|

| Multitasking Machines |

|---|

| Machining Centers |

|---|

| 5-Axis Machining Centers |

|---|

| Double-Column Machining Centers |

|---|

| Grinders |

|---|

Cumulative shipments: 60,000

Development of the Thermo-Friendly Concept continued after the first release in 2001, and the cumulative sales of machines equipped with TFC have passed the 60,000 mark.

Green-Smart Machine

As a step towards turning the decarbonized society into reality, Okuma has defined "Green-Smart Machine" as intelligent machine tools that contribute to resolving environmental issues by autonomously achieving both stable dimensional accuracy and reduced energy usage, and the company offers a full product lineup.