- HOME

- Intelligent Technology

- Collision Avoidance System

Intelligent Technology

- Allowing operators to focus on making parts

- CAS prevents collisions in automatic or manual mode, providing risk-free protection for the machine—and great confidence for the operator.

-

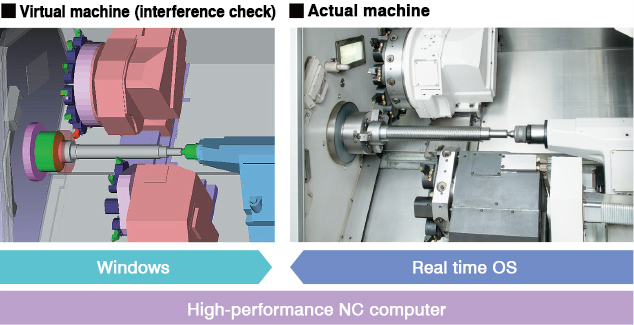

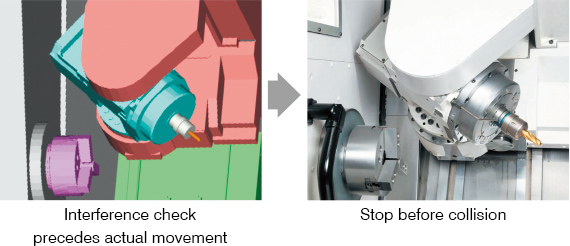

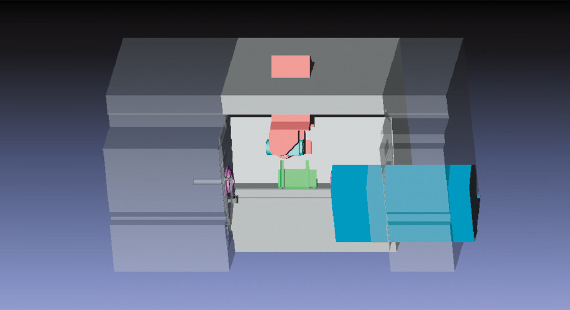

- Collision prevention during automatic operation

- NC program is read in advance and axial travel commands are checked for interference with consideration of zero point and tool compensation values set in NC. Axial travel movement is stopped temporarily before collision occurs.

-

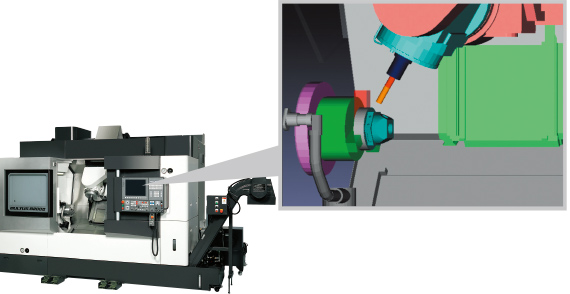

- Collision avoidance in manual operation

- Especially useful for machine operators setting up a job, collision avoidance in manual mode provides collision-free confidence and faster machining preparations.

-

- Realistic simulation of workpiece cutting

- Workpiece shape during machining is displayed accurately and interference checks are performed.

-

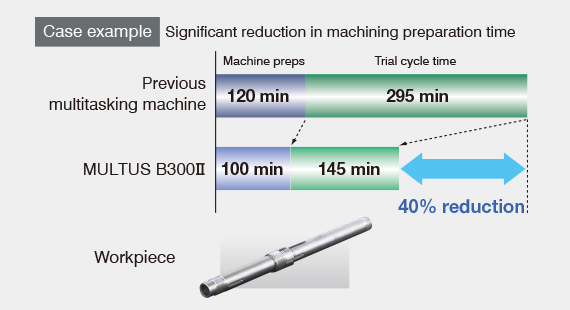

- Improved spindle utilization

- Fewer interference checks performed by operators when spindle and turret approach. First part cycle time is shortened.

- Operator confidence and enhanced functionality

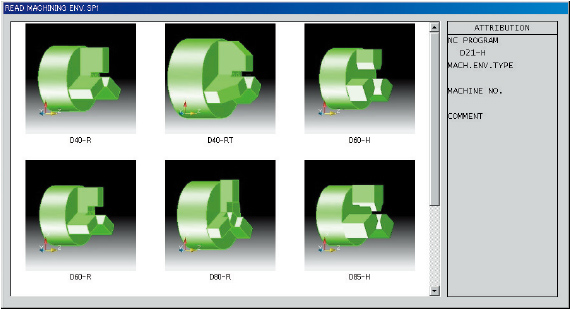

- Simple input of setup information! Easy modeling

-

-

- 1. Machine (settings done)

-

- 3D model of machine is registered

- Automatically selected setting for startup

-

- 2. Select chuck (fixture)

-

- 3D models of standard chucks already stored

- Selection inputs from stored 3D models

3D models (STL) created with CAD can also be read. -

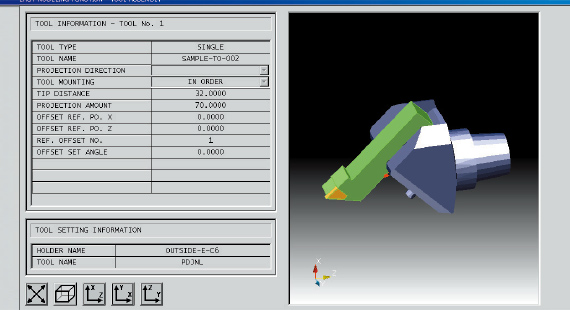

- 3. Select tools

-

- 3D models of standard tools already stored

- Selection inputs from stored 3D models

User-created tool profiles and 3D models (STL) can also be read. -

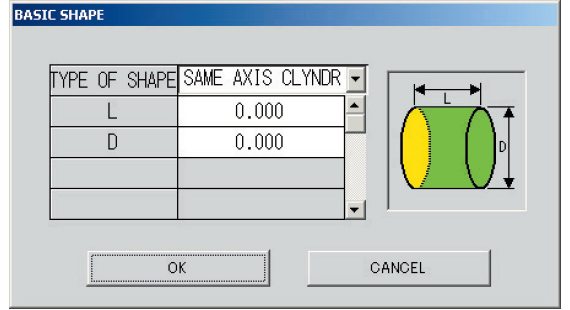

- 4. Enter blank shapes

-

- Interactively enter basic configurations

Also accepts end-user STL 3D models.

-

Application example

-

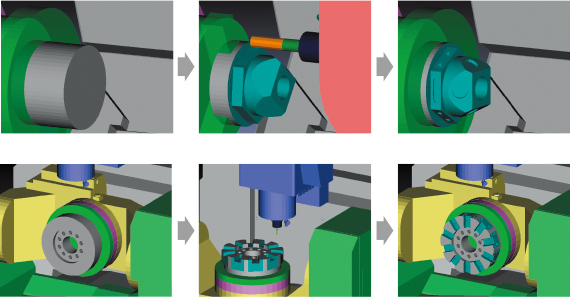

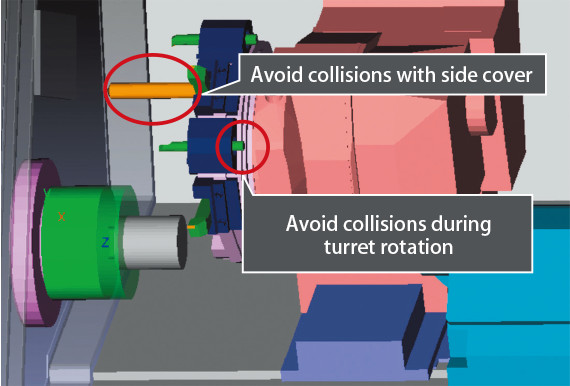

- Collision avoidance during turret rotation, movement

- Unforeseen collisions of long tools with turret rotation and travel can be avoided. The operator can concentrate on the machining without worry of collisions.

-

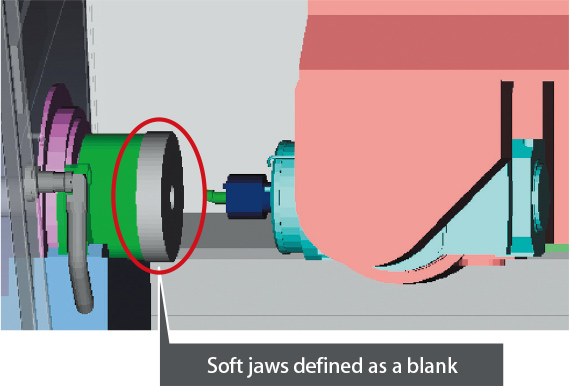

- Interference checks during soft jaw forming

- Since jaws are fixture models, the Collision Avoidance System cannot normally be used during soft jaw forming. However, by defining the jaw shape as a blank material model, CAS can be used.

- Caution

- The Collision Avoidance System is a system that detects collisions based on 3D models of the machine components, tools, fixtures, and workpieces stored in the OSP. Thus, if the entered tool, fixture, workpiece shape differs from their actual dimensions, CAS will not accurately detect possible collisions. In some cases, the units or movements that are subject to collision detection may be limited.