- HOME

- Intelligent Technology

- Machining Navi

Intelligent Technology

Maximizing machine tool performance

With graphical representation of machine performance, the operator can easily select optimal cutting conditions.

-

Milling example -

Turning example

Tailored approaches for different types of machine tool

- Optimizing spindle speed

- Especially suitable for high-speed milling applications, to effectively suppress chatter by shifting rpm's to an optimum, and even faster chatter-free zone.

(Machining Navi, M-i, M-gⅡ , M-gⅡ+)

- Raising the low-speed threshold—

[milling and turning applications] - Increasing milling or turning spindle speeds in the slow zone requires a different approach to suppress chatter. Okuma's solution provides a wider stable region for faster cutting in the low-speed zone.

(Machining Navi, M-i, M-gⅡ+, L-g)

Four types of Machining Navi easily guide customers

-

Simple, auto-mode—leave it to the machine

Finding optimum cutting conditions quicklyMachining Navi M-i

(intelligently optimized spindle speed control) -

Adjust cutting conditions while monitoring the data

Machining Navi M-gⅡ

(guided optimization of spindle speed)Machining Navi M-gⅡ+

(guided optimization of spindle speed/harmonic control) -

Chatter-free applications for lathes

Machining Navi L-g

(guided, harmonic spindle speed control) -

Threading chatter can be easily controlled by anyone

Machining Navi T-g (threading)

Cutting condition search function for milling

Machining Navi M-i (intelligently optimized spindle speed control)

Simple, auto-mode—leave it to the machine (Auto Control)

Chatter vibration is measured by builtin sensors, and Machining Navi automatically changes spindle speed to the optimum speed. In other words, vibration measurement, optimum spindle speed calculations and spindle speed adjustments are then made automatically.

Finding the best cutting conditions quickly

Advanced graphics of the optimal cutting conditions represent effective alternatives to suppress various chatter characteristics throughout the low to high speed zones. In addition to Auto Control, this can be used as a tool to raise cutting conditions even further.

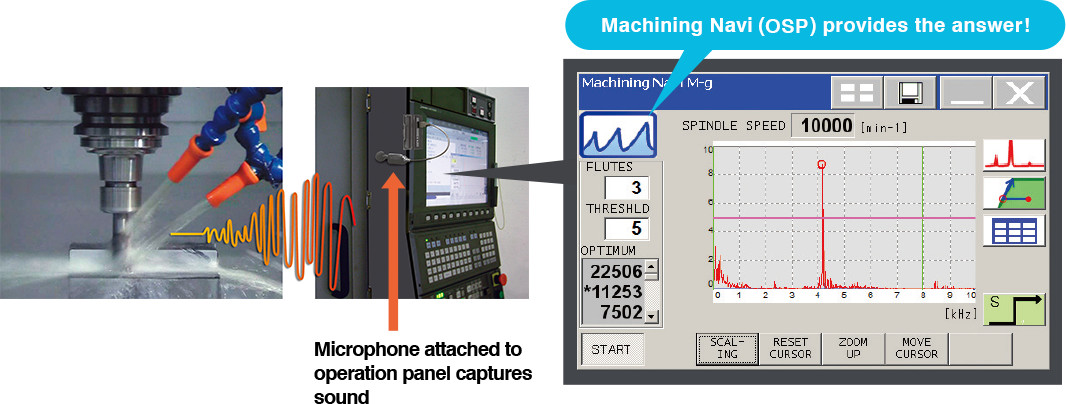

Cutting condition search function for milling

Machining Navi M-gⅡ (guided optimization of spindle speed)

Machining Navi M-gⅡ+ (guided optimization of spindle speed/harmonic control)

Adjust cutting conditions while monitoring the data

Based on the chatter noise captured by the microphone, Machining Navi displays a number of optimal spindle speed possibilities on the screen. The operator can change to the indicated spindle speed with a single touch and immediately confirm the result.

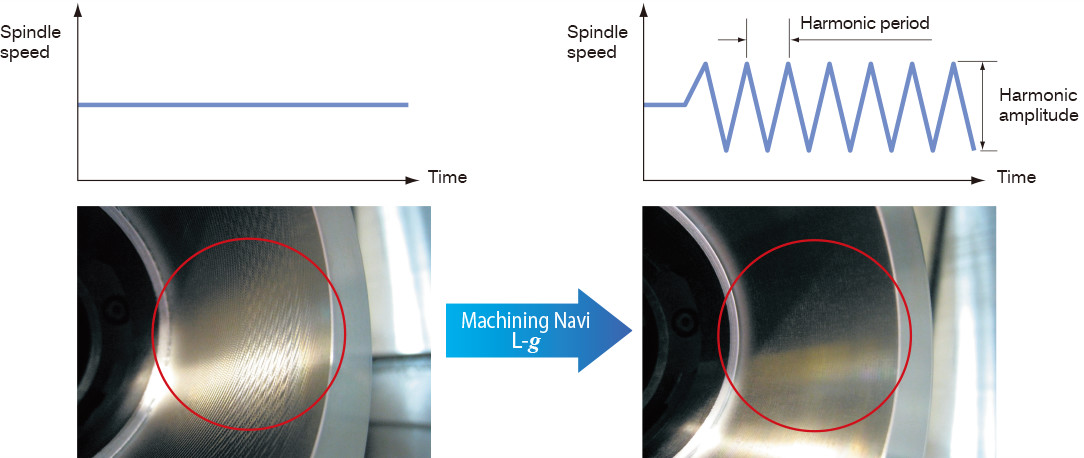

Cutting condition search function for turning

Machining Navi L-g (guided, harmonic spindle speed control)

Chatter-free applications for lathes

Chatter in a lathe can be suppressed by changing spindle speeds to the ideal amplitude and wave cycle—without decreasing spindle speed.

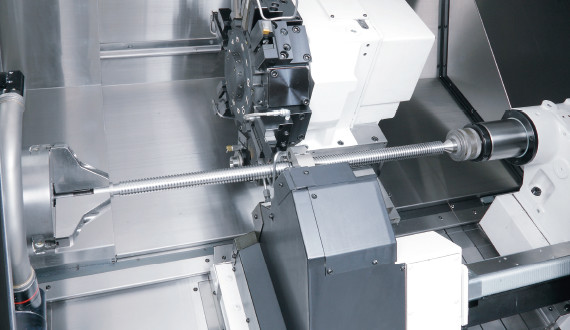

Cutting condition search in threading

Machining Navi T-g (threading)

Threading productivity is improved while costs are kept down

When chatter occurs in threading, general methods to resolve the problem have been to either lower cutting conditions at the expense of productivity, or to use special chatter-resistant tools at some cost. Machining Navi T-g (threading) provides optimum control, increasing or decreasing spindle speed on each pass to inhibit the periodic vibrations that are a cause of chatter.

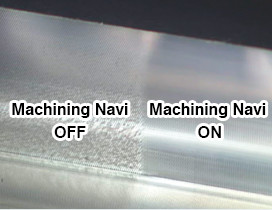

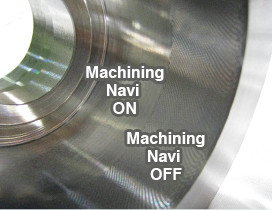

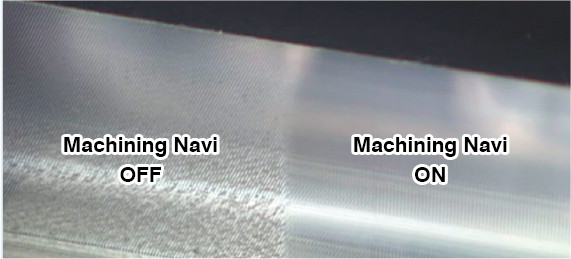

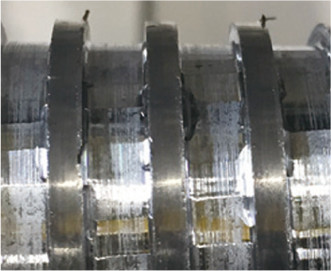

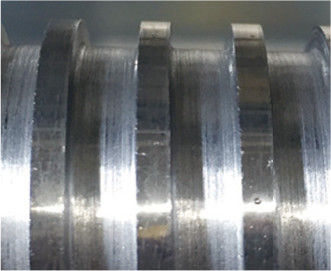

- Example of Machining Navi T-g (threading)

- Chatter occurs and machining is stopped even when an auto follower rest is used in threading of long materials of L/D = 23. With Machining Navi “ON,” good machined surfaces are obtained by machining the remaining paths even with workpieces in which chatter had occurred.

- Workpiece: ø34 × 798 mm

- Material: S45C

- Square threading: Auto follower rest was used.

<Normal threading>

- Spindle speed

-

- 1st pass: 1400

- 2nd pass: 1400

- 3rd pass: 1400

- 4th pass: 1400

- ·

- ·

- Chatter

occurrence

<Machining Navi T-g>

- Spindle speed

-

- 1st pass: 1680

- 2nd pass: 1120

- 3rd pass: 1680

- 4th pass: 1120

- ·

- ·

- Threading

completed