PRODUCTS

Stable accuracy

- Powerful machining of medium to large cubic and odd-shaped workpieces

- The box-type base and column make a highly dependable, highly rigid structure

- Workpiece deadweight pressed on vertical chuck helps stabilize machining

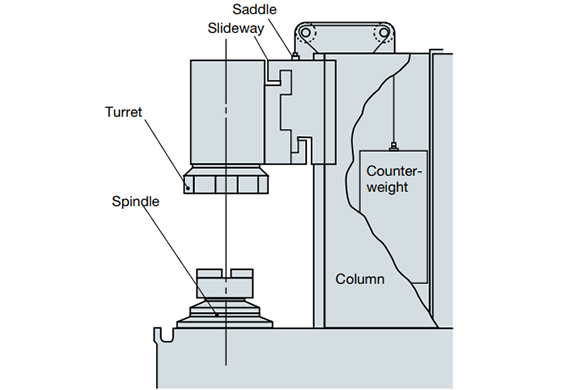

- Highly rigid construction

-

- A strong, square column is positioned on a large, rigid base with good damping properties, and a highly rigid, reliable structure with wide box ways on both the X and Z axes is used.

- Smooth, stable feeds are achieved during low- to high-speed cutting with a counterbalance not affected by feed rate changes.

-

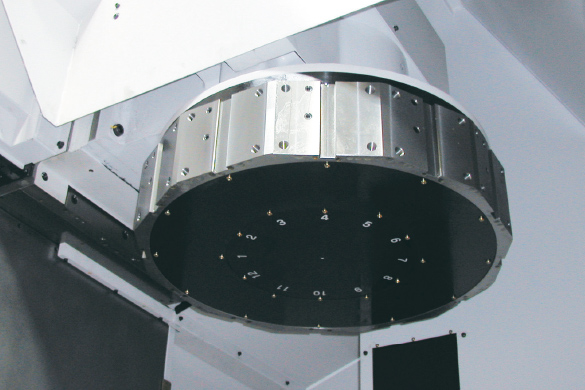

- Turret

-

- Large 12-station turret has adequate space for easy and also permanently set tooling arrangements.

- The large-diameter coupling enables high accuracy indexing and powerful heavy-duty cutting with strong hydraulic clamps.

-

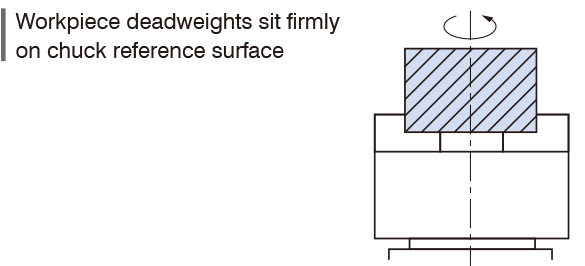

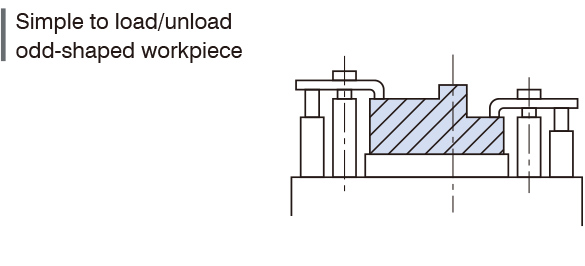

- Stable machining achieved with workpiece deadweight sitting tight on chuck

-

- The workpiece deadweight itself helps provide a firm seat on the chuck reference surface. Without excessive workpiece restraint, distortion and pressure marks can be prevented to achieve highly accurate machining of thin to large and heavy workpieces.

Manual part load/unload, without holding it, is also easy for irregularly shaped workpieces that require clamps.

- The workpiece deadweight itself helps provide a firm seat on the chuck reference surface. Without excessive workpiece restraint, distortion and pressure marks can be prevented to achieve highly accurate machining of thin to large and heavy workpieces.

Powerful machining

- Using motors with wide constant-power ranges

- Headstock with flange construction to minimize effects of thermal deformation and vibration

- Spindle

-

- The headstock has a flange construction and is solidly fixed to a box-type base. This minimizes the effects of thermal deformation and vibration.

- A powerful motor with a wide constant-power range is used for the spindle. Combining this with a big bore spindle enables powerful heavy-duty cutting.

| V40R/2SP-V40 | V100R | |

|---|---|---|

| Spindle type | A2-8 | Flat ø380 (14.96) |

| Outside diameter |

ø120 (4.72) | ø200 (7.87) |

| Inside diameter |

ø77 (3.03) | ø110 (4.33) |

mm(in.)

High productivity

- Zero WIP (work in progress) with process-intensive machining.

- Raise productivity with multitasking applications.

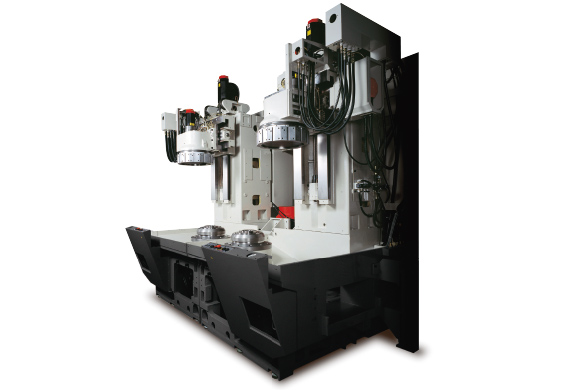

- Two-spindle lathe (2SP-V40):

High productivity with double the performance on one machine -

- Because of the separate L/R structures, machining vibration does not affect the other spindle.

Highlighted Specs

| Item | Unit | V40R [2SP-V40] |

V100R |

|---|---|---|---|

| Applicable chuck sizes | in | 12, 15, 18 | 36, 40 |

| Max turning dia | ømm (øin) | 400 (15.75) | 1,000 (39.37) |

| Max work length (height) | mm (in) | 450 (17.72) | 890 (35.04) |

| Spindle speed | min-1 | 2,500 | 1,250 |

| Turret | V12 | V12 | |

| Motor | kW (hp) | 22/18.5 (30 min/cont) (30/25) | 30/22 (30 min/cont) (40/30) |

| Machine size (W × D × H) |

mm (in) | 1,705 × 2,788 × 3,040 (67.13 × 109.76 × 119.69) [2,970 × 2,738 × 3,040] (116.93 × 107.80 × 119.69) |

2,735 × 3,445 × 3,510 (107.68 × 135.63 × 138.19) |

| Spec extension | M | M | |

| CNC | OSP / FANUC | OSP / FANUC |

M: Milling