PRODUCTS

Quick movement and a compact structure enables fast and stable production

Improvement of productivity (shorter tact time)

Workpiece load/unload time

Load/unload time of 4.1 seconds

Loader tact time of 19.8 seconds (includes time for oriented spindle stop and seating detection)

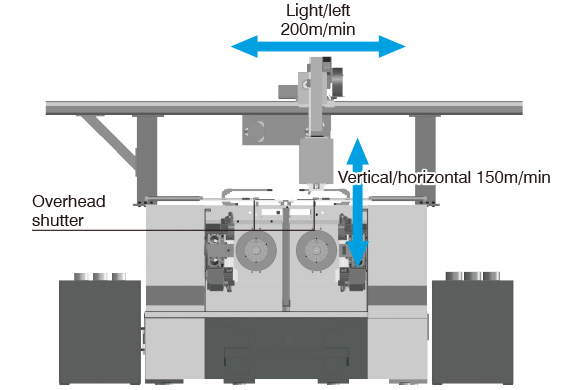

High-speed loader

Light/left 200m/min Vertical/horizontal 150m/min

Overhead shutter, horizontal open/close type

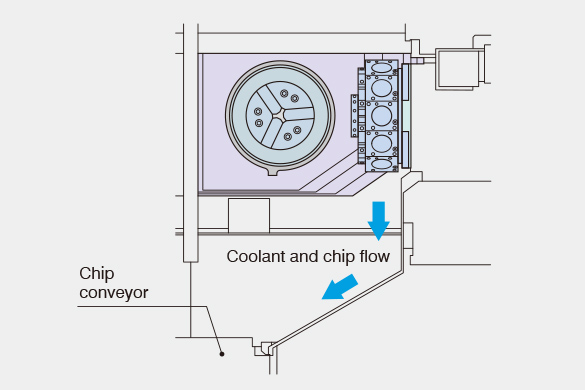

Stable continuous machining, improvement of chip discharge ability

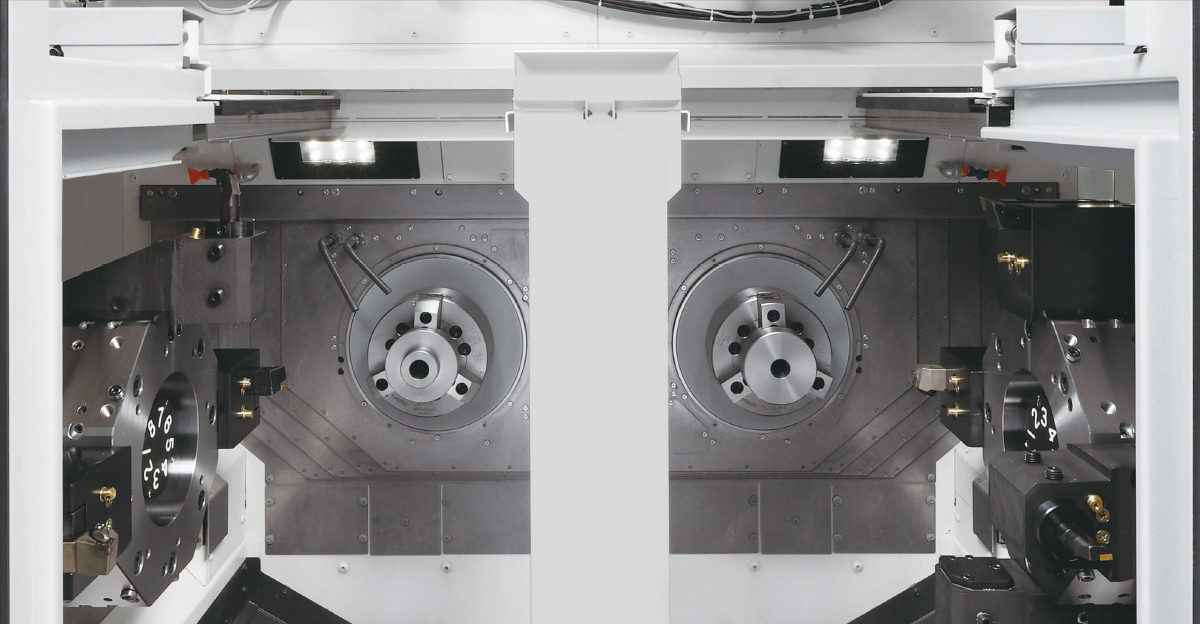

Turret structure that prevents chips from sticking to tools

Rotating turret allows chips stuck on the tools to drop

In-machine cover that prevents chips from accumulating in the machine

- Covering design that keeps the slideway outside the machining chamber

- Vertical cover design makes chip discharge easy

- The short distance to the chip conveyor ensures smooth chip flow

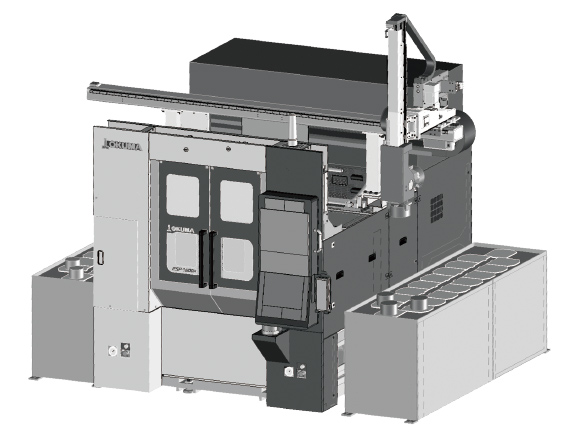

Simple & flexible

Construction of an optimal system

Easy construction of an automated system with loaders

With no need to conduct maintenance from the sides of the machine, creating layouts for automation-related peripheral equipment is easy.

The part-flipper device on the machine minimizes the tact time.

The vertical slide work gripper is compact and causes no interferences, making it ideal for small workpieces.

Highlighted Specs

| Item | Unit | 2SP-1500H |

|---|---|---|

| Standard chuck size | inch | 6, 8 |

| Max turning dia | mm (in) | ø290 (ø11.42) |

| Max work length | mm (in) | 160 (6.30) |

| Spindle speed | min-1 | 6,000 |

| Turret | L/R: V8 | |

| Motor | kW (hp) | 15/11 (30 min/cont) (20/15) |

| Machine size (W×D×H) |

mm | 1,900×2,605 (machine only) × 2,983 (max loader ht) |

| Spec extension | L | |

| CNC | OSP-P300LA |