PRODUCTS

- Stable, high-accuracy grinding

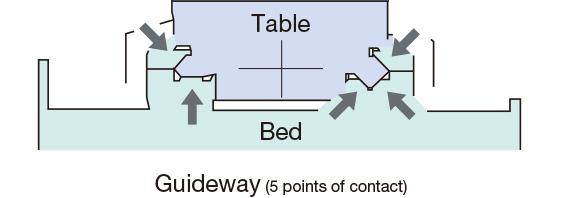

- Traditional Okuma 5-sided hydrostatic guideway

- Both cross-slide and table always raise with oil to achieve high follow-up accuracy.

- Higher rigidity with support on 5 sides from upper and lower portions of slide.

- Distance between two guideways is wide, and vibration absorption characteristics are improved simultaneously with high speed and high rigidity.

- With closed structure holds top and bottom solidly in place, accuracy and guideway durability are improved.

- The best machines for die/mold contour grinding.

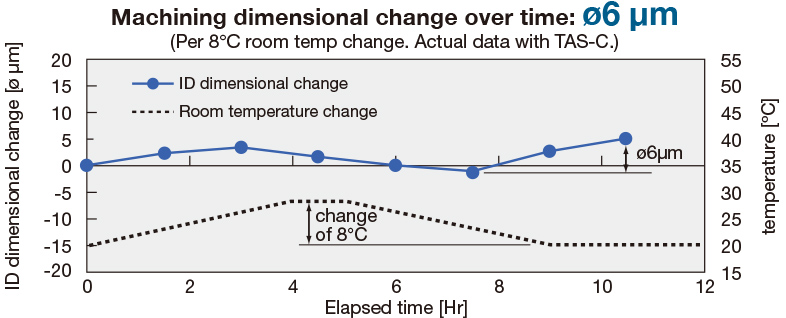

- Thermo-Friendly Concept

- The Thermo-Friendly Concept delivers high machining accuracy with a unique machine construction design and thermal deformation control technology. The Thermo-Friendly Concept releases you from bothersome dimension compensation and warming-up, and provides outstanding dimensional stability even during long-time operation or changes in the plant temperature environment.

- Achieves high thermal stability not only during room temperature change, but also at machine startup and restarts.

- Thanks to stabilized thermal deformation, warming-up time is shortened and the burden of dimensional correction during machining restart is reduced.

※ This (TFC) is not available with 4WS and belt-driven grinding wheel specs.

※ The above are actual examples. Your results may vary due to differences in specifications, tooling and cutting conditions.

- Greater machining efficiency

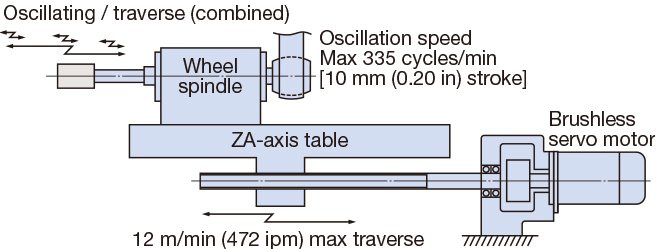

- Benefits of numerically controlled oscillating traverse

- Higher removal rates, lower cycle times

- Improved surface roughness compared to conventional traverse grinding

- Ideal for long workpieces

-

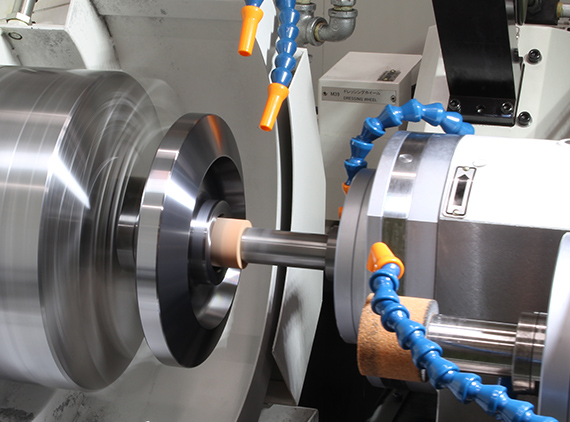

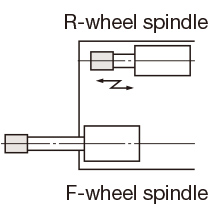

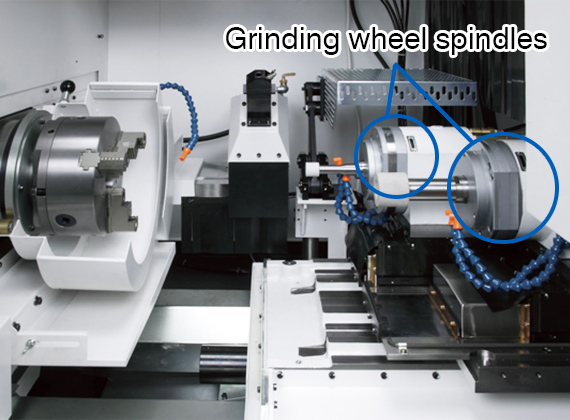

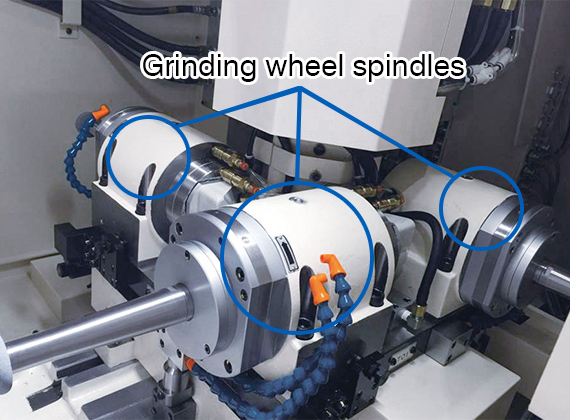

- 2-wheel spindle (2WS)

-

Expanded range of uses for grinding wheel, including cylindrical and internal grinding, roughing, and finishing.

-

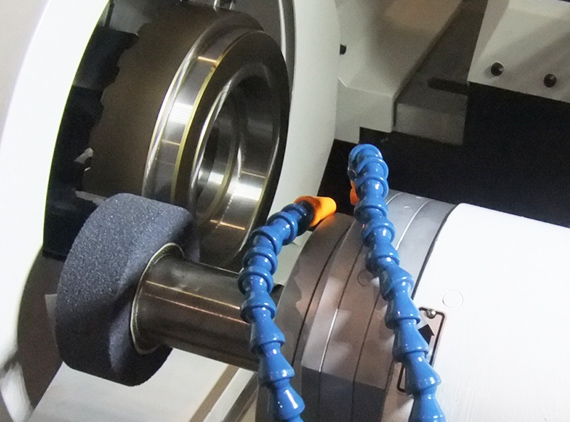

- 4-wheel spindle (4WS)

-

Up to 4 high frequency grinding wheel spindle sets can be mounted, enabling greater diversity of integrated grinding operations than with 2WS, and more efficient grinding.

Highlighted Specs

| Item | Unit | GI-20NⅡ |

|---|---|---|

| Spindle support capacity mass × length | kg × mm (lb × in) |

150 × 200 (330 × 7.87) |

| Swing in chuck guard | ømm (øin) | 400 (15.75) |

| Bore grinding | ømm (øin) | 5 to 300 (0.20 to 11.81) |

| Max grinding depth | mm (in) | 200 (7.87) |

| Wheel motor | kW (hp) | 5.5 (7.5) |

| Machine size (W × D × H) |

mm (in) | 2,490 × 3,023 × 1,808 (98.03 × 119.02 × 71.18) |