PRODUCTS

- Meeting capacity and accuracy requirements with high productivity

- Achieve a powerful, high-quality machining

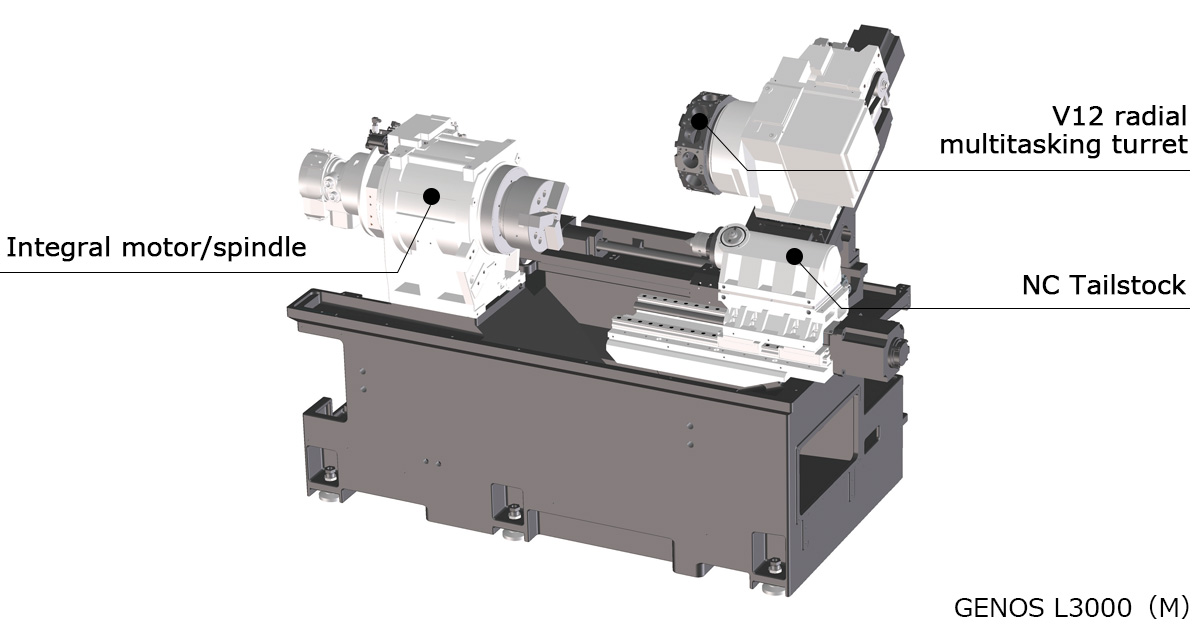

- The integral motor/spindle provides fast and high output with high machining capacity—at high quality.

And Okuma’s legendary slide guideways are highly rigid to handle powerful cutting loads that result in high productivity.

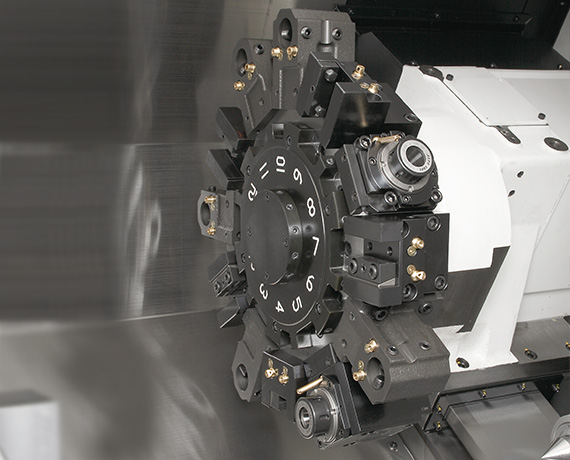

Two types of turrets are available, the V8 and V12 turrets. Select the one best suited to the machining you do.

High accuracy milling

-

Milling tools can be attached to all locations on turrets with milling specifications. With a spindle indexing command of 0.001°, high accuracy milling can be done at any angle. Two types of multitasking turrets, VDI and radial, are available on the GENOS L3000.

-

V12 radial multitasking turret (Optional)

Simplified shaft work fixturing

-

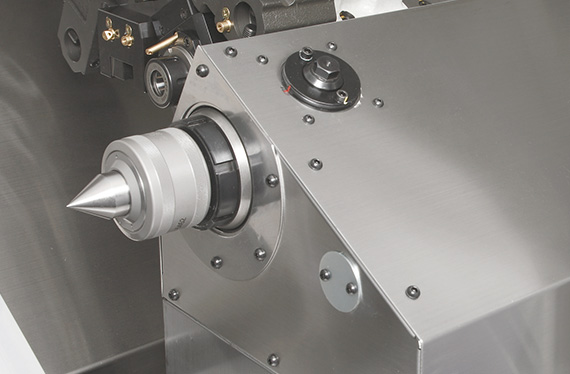

Servomotor control NC tailstock is used for the tailstock.

Travel and thrust can be set with program commands, greatly increasing ease of use. Setup change can also be easily done.Tailstock specifications

GENOS L2000 GENOS L3000 Tailstock thrust 1.0-2.0kN 1.0-5.0kN Rapid traverse 12m/min Approach 10m/min Retract 12m/min -

Excellent user-friendliness allows operators to concentrate on the work

-

- Machine designed for good accessibility

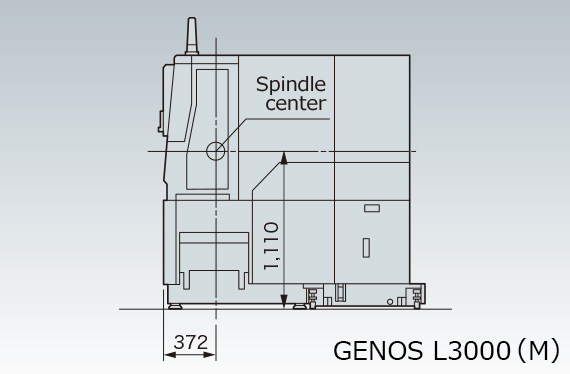

- Spindle access is good with 372 mm from the machine front face to the spindle center, reducing the work burden of operators.

-

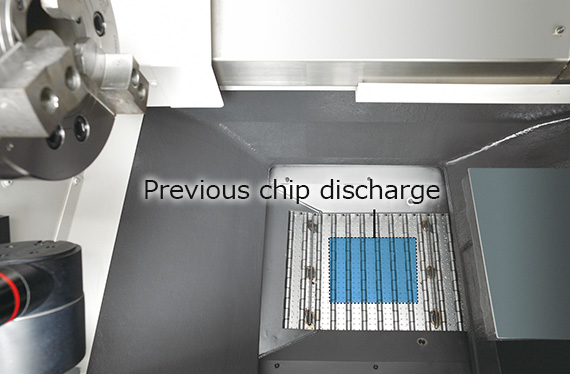

- Outstanding chip discharge

- The chip discharge outlet is 2 times larger than on previous machines, minimizing chip accumulation. The cleaning frequency is reduced for maximum operation time.

Specifications may vary in different markets.