PRODUCTS

With overwhelming cutting ability,

for machining large parts of heavy industry

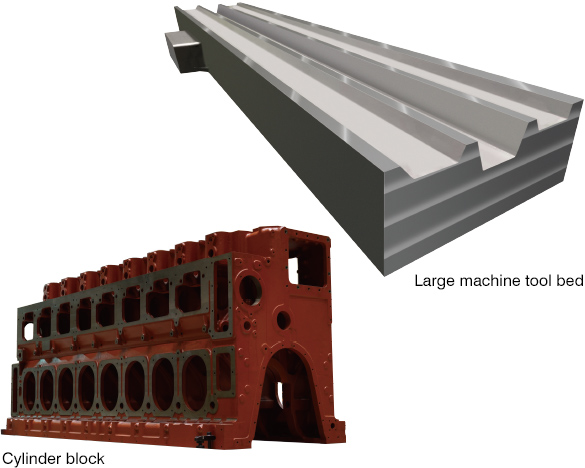

Achieving highly efficient roughing to highly accurate finishing of the super large parts of heavy industry, with this one machine.

Industries

Installed in machine shops producing large parts requiring powerful, high output and high torque applications.

Feature

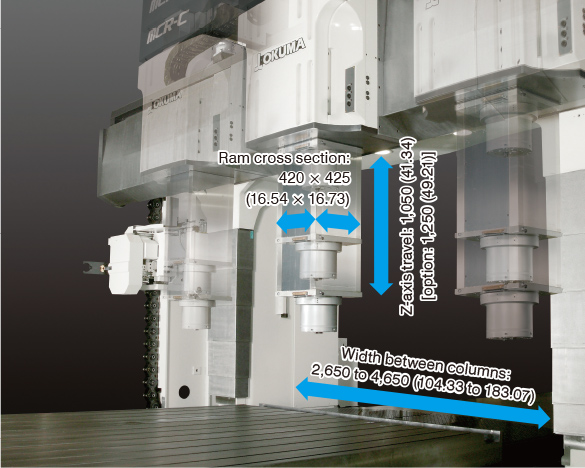

01 High rigidity, powerful cutting Highly rigid ram with 420 × 425 mm cross section

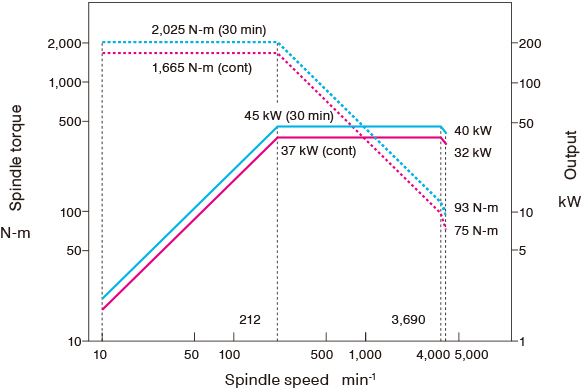

Max torque: 2,025 N-m

Equipped with gear driven ram spindle to deliver powerful machining

Ram structure with the largest cross-sectional area in the Okuma series of double columns. The ram rigidity supports powerful cuts with horizontal spindles.

-

- Ram size:

- 420 × 425 mm (16.54 × 16.73 in)

-

- Spindle speed:

- 4,000 min-1 (gear)

-

- Max output:

- 45/37 kW (60/50 hp) (30 min/cont)

-

- Max torque:

- 2,025/1,665 N-m

(30 min/cont)

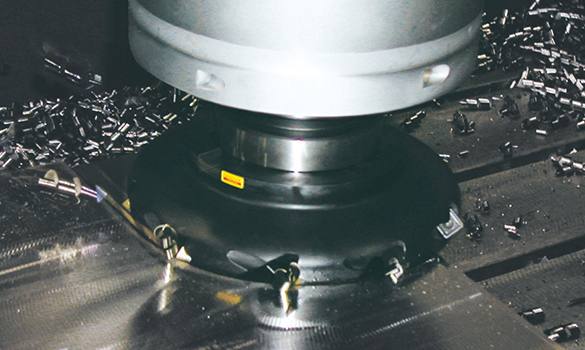

High output extension heads (option)

-

- Machining capacity:

- 1,210 cm3/min

(spindle bearings ID: ø130, L250)

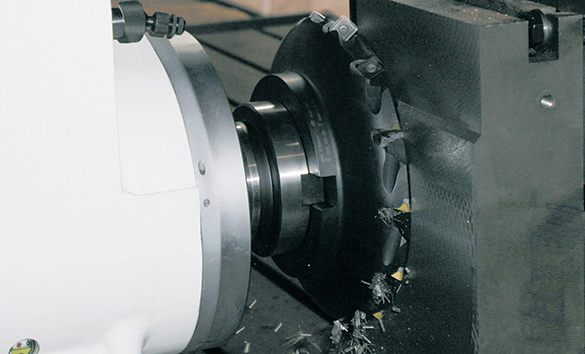

ø250 mm 10-blade face mill

-

- Cutting feed rate:

- 188 m/min

-

- Infeed × cutting width:

- 8 × 175 mm

-

- Feed rate:

- 864 mm/min (0.36 mm/blade)

High output 90° angular attachment head (option)

-

- Machining capacity:

- 1,075 cm3/min

(spindle bearing ID: ø130, L270)

ø250 mm 10-blade face mill

-

- Cutting feed rate:

- 188 m/min

-

- Infeed × cutting width:

- 8 × 175 mm

-

- Feed rate:

- 768 mm/min (0.32 mm/blade)

02 Large work envelope Wide width between columns, long travels handle big and tall parts

-

Z-axis travel:

1,050 mm (41.34 in)

[option: 1,250 mm (49.21 in)] -

Max width between columns:

4,650 mm (183.07 in)

(45 model) -

Long travel:

12,200 mm (480.31 in)

(X-axis) -

Max table top to spindle nose:

4,000 mm (157.48 in)

[high column + 2,200 mm (86.61 in)]

Note: The data shown here represent "actual data," which may not be obtained under different environmental, machine specifications, tooling, cutting, and other conditions.

Highlighted Specs

| Item | Unit | MCR-C |

|---|---|---|

| Effective width between columns | mm (in) | 2,650 to 4,650 (104.33 to 183.07) |

| Table working surface | mm (in) | 2,000 × 4,000 to 3,700 × 12,000 (78.74 × 157.48 to 145.67 × 472.44) |

| Spindle speed | min-1 | 4,000 |

| Tool storage | tools | 50 |

| Motor | kW (hp) | 45/37 (30 min/cont) (60/50) |

| Machine size (W × D × H) |

mm (in) | 7,810 × 10,730 × 6,620 to 9,895 × 27,930 × 7,200 (307.48 × 422.44 × 260.63 to 389.57 × 1,099.61 × 283.46) |