PRODUCTS

Super rugged, high-precision construction

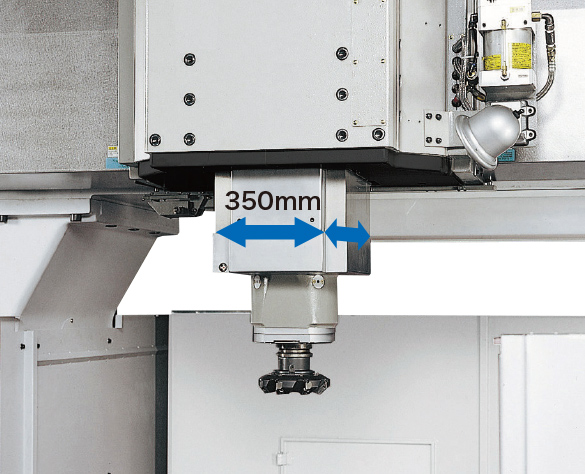

Ram-type spindlehead for super rigidity

With a cross section of 350 x 350 mm (13.78 × 13.78 in) there's enough rigidity in the square ram-type spindlehead to handle any heavy-duty machining.

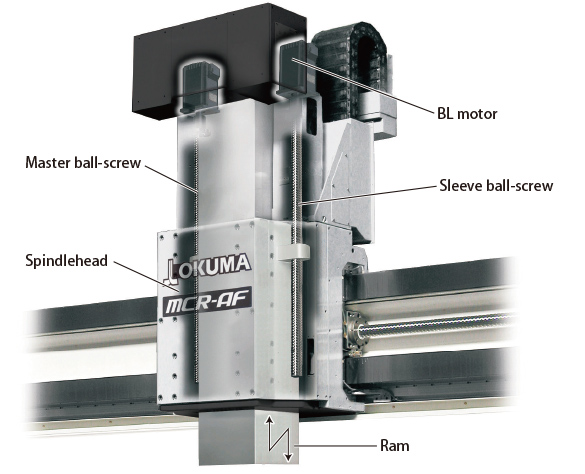

Z-axis twin ball screws + AbsoScale (Std)

The Z axis is controlled with double ball screws that drive bothsides of the ram.

A high level of straightness is achieved on the Z axis.

0.003 mm/800 mm (0.00012 in/31.50 in)

Powerful, highly accurate, and high-speed machining fully supported by slide/roller guideways

Powerful and highly accurate machining

Rationally designed combination slide/roller X-Y guideways absorb cutting vibration, and with rollers taking on the weight, movements are smooth, providing superb accuracies, positioning, and stable operations over long periods.

High-speed feedrate

Multitasking slide/roller guideways provide better

- Rapid traverse 20 m/min (X, Y axes) (787 ipm)

- Cutting feedrate 10 m/min (394 ipm)

Highlighted Specs

| Item | Unit | MCR-AF |

|---|---|---|

| Effective width between columns | mm (in) | 2,600 (102.36) |

| Table working surface | mm (in) | 2,000 × 1,500, 2,000 × 2,000 (78.74 × 59.06, 78.74 × 78.74) |

| Spindle speed | min-1 | 8,000 |

| Tool storage | tools | 24 |

| Motor | kW (hp) | 26/22 (30 min/cont) (35/30) |

| Machine size (W × D × H) |

mm (in) | 5,560 × 4,200 × 4,670, 5,560 × 5,230 × 4,670 (218.90 × 165.35 × 183.86, 218.90 × 205.91 × 183.86) |