PRODUCTS

A superb general-purpose machine

for smaller footprint and better cost-performance

A machine with excellent cost-performance that brings together the best of Okuma’s technology into a space-saving design.

We are delivering high productivity to various machine shops, for general parts to high-accuracy applications.

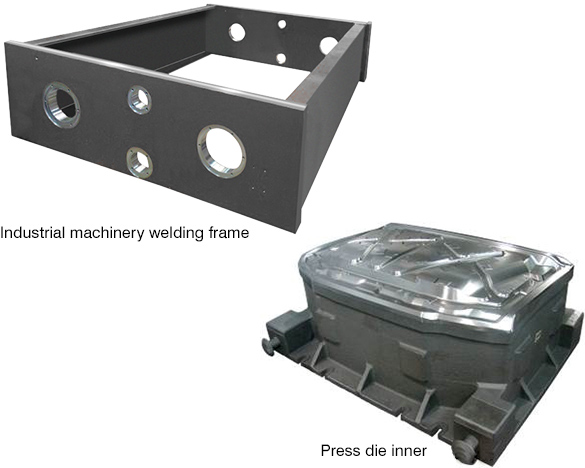

Industries

By taking advantage of the easy to install, space-saving performance, a variety of industrial and transportation equipment machine shops are benefiting from effective parts applications.

Feature

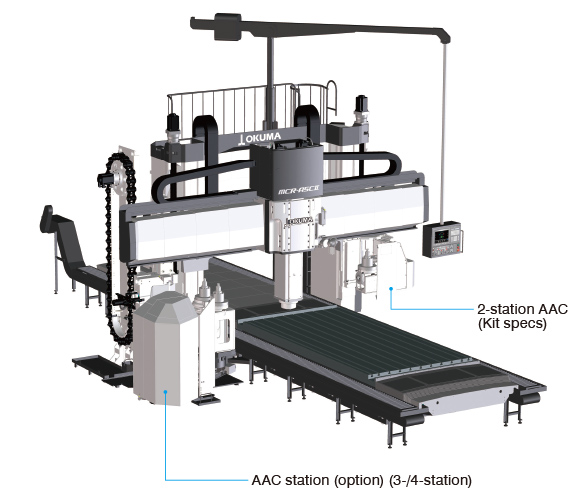

01 Space saving 2-station AAC placed on the right column side minimizes machine width

Compact AAC (Auto Attachment head Changer)

Auto load/unload and ATC to attachment heads enable completely automatic multi-face machining. Column right side mounted AAC also allows fully automated changing of extension and 90° angular heads.

-

AAC time: 36seconds (Machine size: 25 × 40; actual data)

02 5C KitsKit specifications available for general-purpose 5-face machining

Extension heads

-

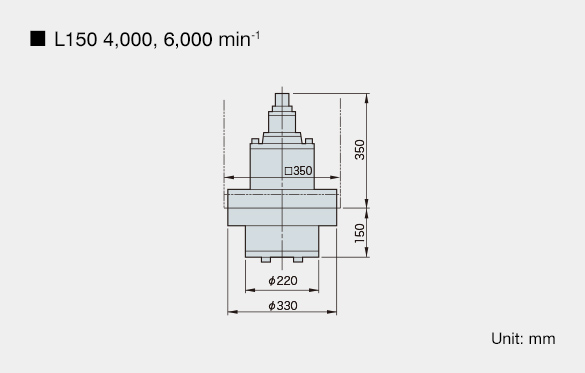

- Machining capacity:

- 710 cm3/min

(spindle bearing ID: ø100 L150)

ø160 mm 8-blade face mill

-

- Cutting feed rate:

- 221 m/min

-

- Infeed × cutting width:

- 5 × 112 mm

-

- Feed rate:

- 1,267 mm/min (0.36 mm/blade)

-

- Z-axis protrusion:

- 800 mm

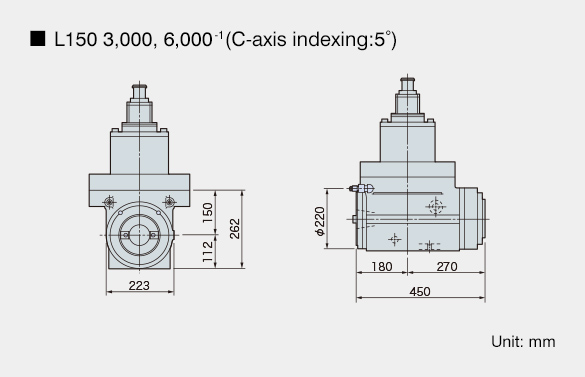

90° angular head

-

- Machining capacity:

- 600 cm3/min

(spindle bearing ID: ø100 L150)

ø160 mm 8-blade face mill

-

- Cutting feed rate:

- 221 m/min

-

- Infeed × cutting width:

- 5 × 112 mm

-

- Feed rate:

- 1,071 mm/min (0.30 mm/blade)

-

- Z-axis protrusion:

- 800 mm

Note: The data shown here represent "actual data," which may not be obtained under different environmental, machine specifications, tooling, cutting, and other conditions.

Highlighted Specs

| Item | Unit | MCR-A5CⅡ |

|---|---|---|

| Effective width between columns | mm (in) | 2,150 to 3,650 (84.65 to 143.70) |

| Table working surface | mm (in) | 1,500 × 3,000 to 3,000 × 12,000 (59.06 × 118.11 to 118.11 × 472.44) |

| Spindle speed | min-1 | 4,000 |

| Tool storage | tools | 50 |

| Motor | kW (hp) | 26/22 (30 min/cont) (35/30) |

| Machine size (W × D × H) |

mm (in) | 6,180 × 8,430 × 5,820 to 7,780 × 27,930 × 6,300 (243.31 × 331.89 × 229.13 to 306.30 × 1,099.61 × 248.03) |