PRODUCTS

- Offering high-mix, low-volume (HMLV) and mass production from an incredible machine

- The MU-S600V is a 5-axis VMC that simultaneously achieves ease of use, great productivity as a stand-alone, and more innovation with two or more connected configurations. It is a totally new concept of smart machine, offering complete control of applications from high-mix, low-volume production (HMLV) to mass production with just this "one-of-a-kind" machine.

- A single machine

-

A super compact and easy-to-use smart machine

- Connecting 2 machines

-

The tables collaborate in an innovative Work Handoff System,

for smart production line system applications

- A wide range multiside application with one, smart, compact machine

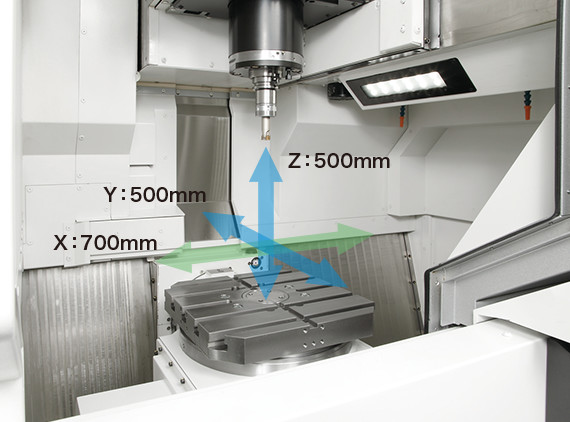

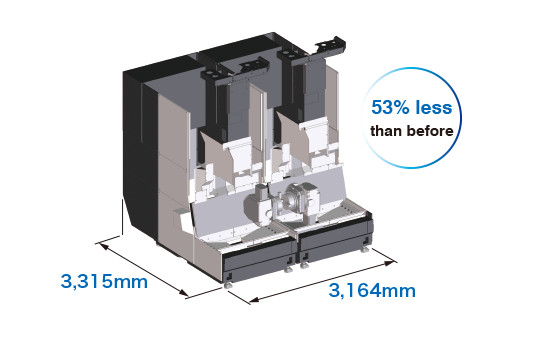

- Compact but with wide machining area

-

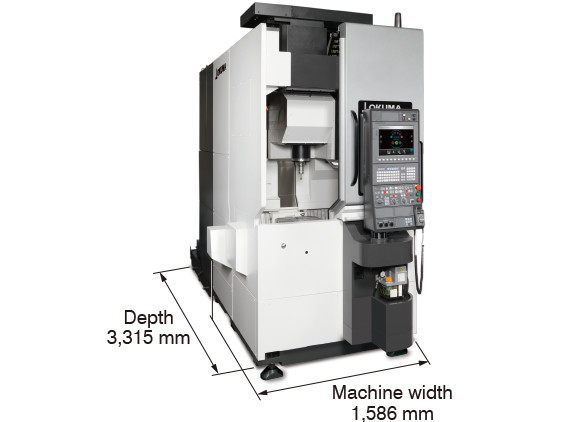

Built with a long X-axis travel of 700 mm in a machine width of just 1,586 mm.

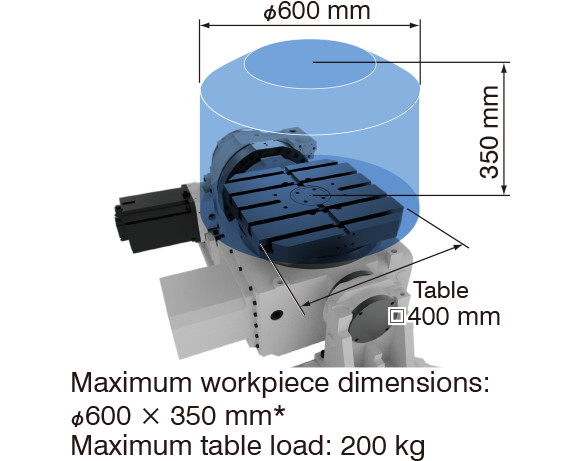

In addition, it is possible to load workpieces up to 600 mm in diameter on the 400 mm square table.

As a 5-axis vertical, Okuma has achieved best-in-class floor space productivity.

- Loadable workpiece size

-

* When transferring workpieces between machines, the maximum workpiece dimensions will differ.

- Space-saving machine

-

- Ideal for multi-sided indexing of castings and aluminum workpieces

- Multi-sided machining is possible with one chucking, making it possible to reduce setup time.

Also, work mounting errors between operations are eliminated, and high machining accuracy can be maintained. -

-

Gearbox case -

Manifold -

Cam box

-

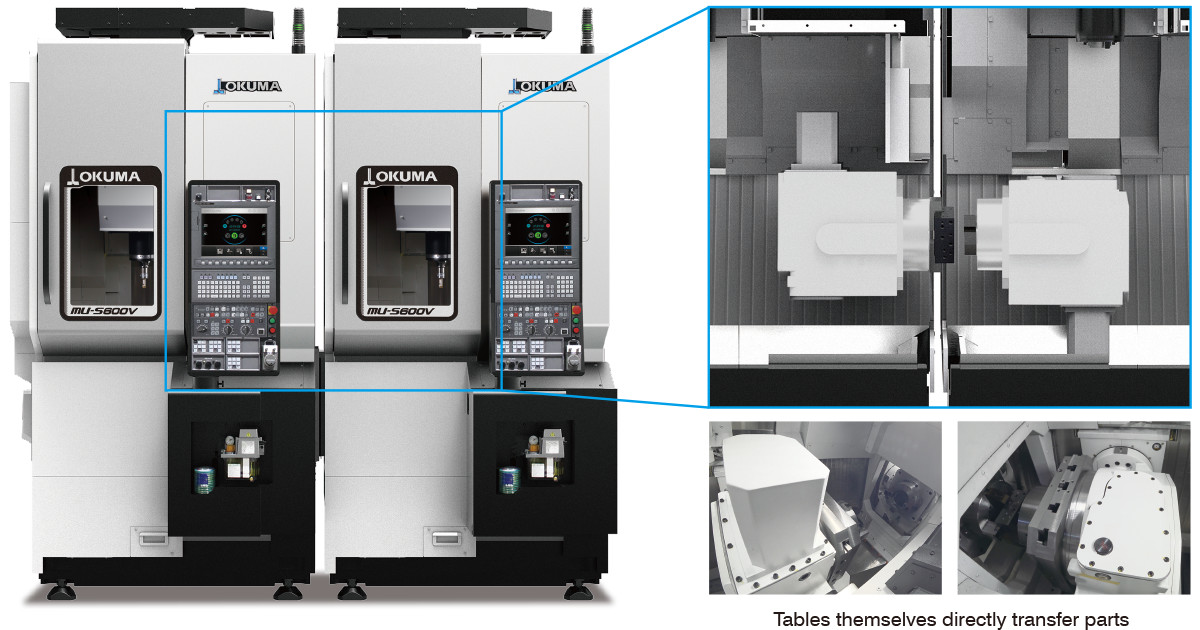

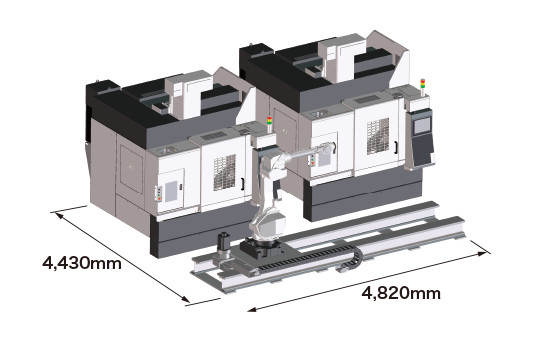

- “Smart production line system” connecting two machines

- Building a compact & automated mass production line

- Compact 5-axis machining with a single machine—connected to another—a smart way to achieve mass production.

The MU-S600V features a built-in Work Handoff System, so the tables of machines connected to each other can transfer parts, eliminating the need for transfer equipment between machines. -

- 〈Smart production line systems〉

- Conventional production line layouts can now be redesigned, to dramatically reduce the floor space of the automated systems.

-

Conventional production line: 22.4 m2(Two 5-axis VMCs + traveling robot) -

Smart production line: 10.5 m2(Two MU-S600Vs)

Highlighted Specs

| Item | Unit | MU-S600V |

|---|---|---|

| Table size | mm(in) | 400 × 400 (15.75 × 15.75) |

| Spindle speed | min-1 | 12,000 |

| Tool storage | tools | 16 |

| Motor | kW(hp) | 15/11 (25% ED/cont) (20/15) |

| Machine size (W × D × H) |

mm(in) | 1,586 × 3,315 × 2,994 (62.44 × 130.51 × 117.87) |