PRODUCTS

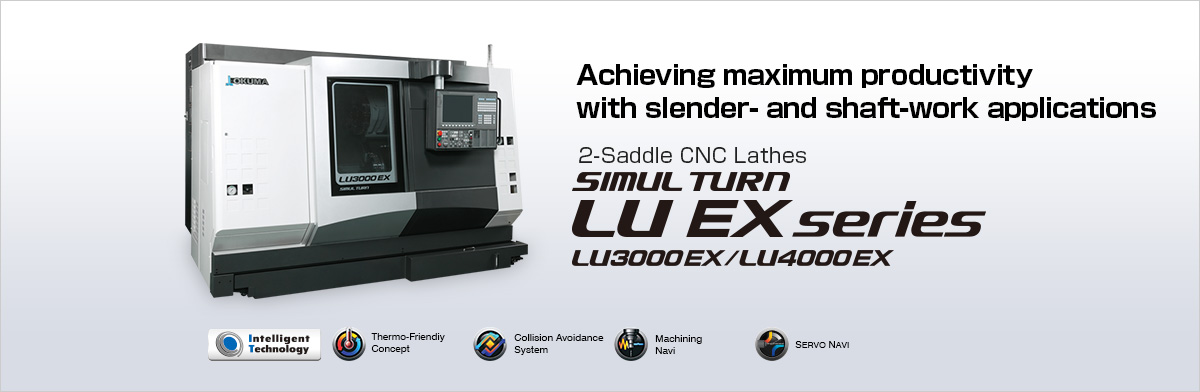

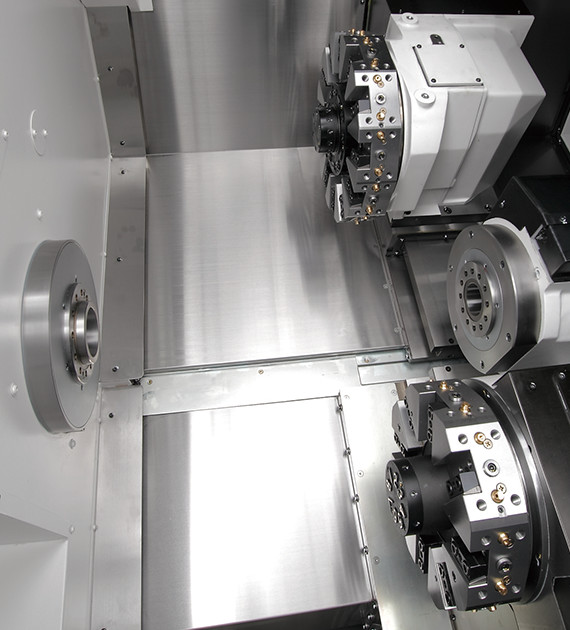

- Many types of machining with the flexibility of 4 axes

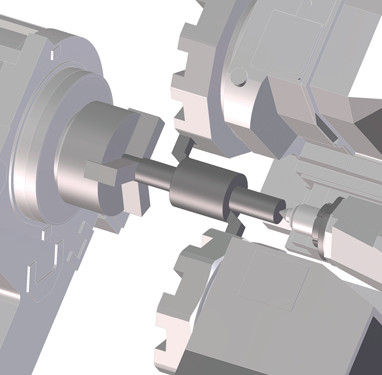

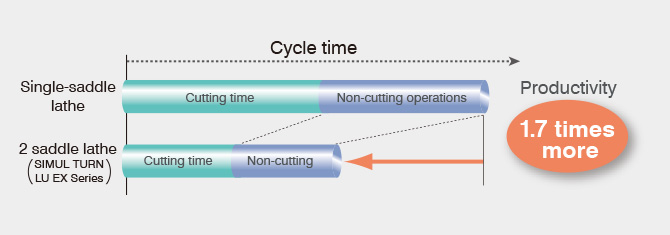

- Huge reduction in machining time with simultaneous 4-axis machining on upper and lower turrets

- In other words, simultaneous OD/OD or ID/OD operations drastically reduce cycle times. In addition with optional turnaround stand and/or a steadyrest attached to the lower turret—the possibilities are endless.

-

High-efficiency machining from simultaneous 4-axis turning

-

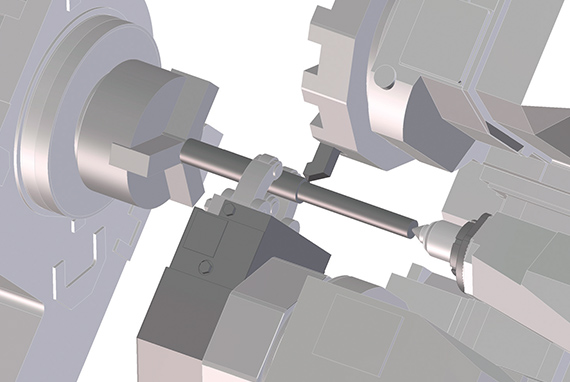

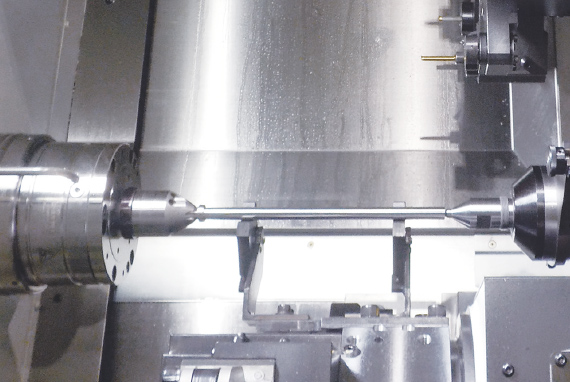

- Turning long shafts with a

steadyrest—without chatter - A steadyrest (optional) mounted on the lower turret does provide steady workpiece support. With an NC programmed upper turret and simultaneous control, long shafts will always be supported near the cutting point.

Prevents chatter with steadyrest support - Turning long shafts with a

-

- Reducing operator burden

by auto part load/unload - A shaft cradle (option) is attached to the lower turret to automate part load/unload, and reduce the workload of the operator.

Shaft cradle reduces operator burden - Reducing operator burden

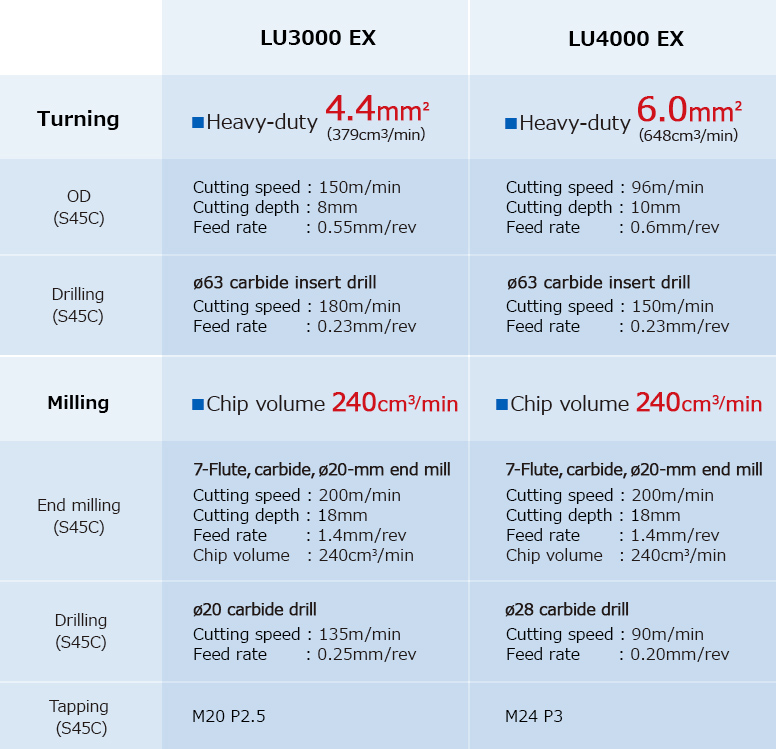

- Powerful machining and rapid movements mean shorter cycle times

- High-performance simultaneous (heavy) turning with power to spare (Actual data)

-

Note: The “actual data” referred to above represent examples, and may not be obtained due to differences in specifications, environmental conditions during measurement, tooling, cutting, and other conditions.

- Achieve the best production system with our wide-ranging lineup

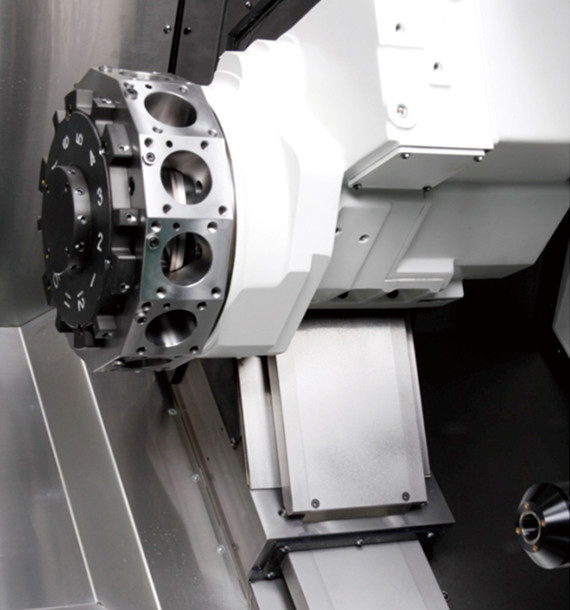

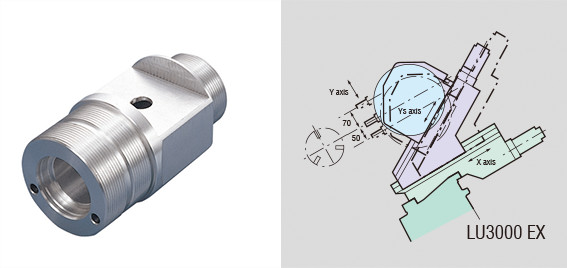

- Complete multitasking with Y-axis functions

One chuck machining even with irregularly shaped workpieces

-

-

A variety of milling operations can be accommodated with high-accuracy, wide-range Y-axis travel using a double slide system. Achieves complete multitasking with a single chucking (MY specifications).

LU3000 EX LU4000 EX Y-axis-travel 120 mm (+70 to −50) 140 mm (+70 to −70) Y-axis rapid traverse 12.5 m/min 12.5 m/min

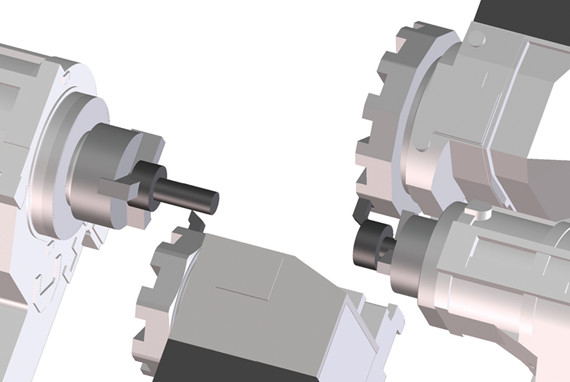

- Sub-spindle for integrated front/back

(1 machine) operations

-

-

With a sub-spindle, front and back machining can be done on a single machine. Since machining of both ends can be completed on one machine, workpiece storage space and post-process machines are unnecessary. (LU3000 EX only)

Highlighted Specs

| Item | Unit | LU3000 EX | LU4000 EX |

|---|---|---|---|

| Standard chuck size | in | 8 | 10 |

| Max turning dia | ømm (øin) | 410 (16.14) | 480 (18.90) |

| Max work length | mm (in) | 600, 1,000 (23.62, 39.37) |

650, 1,250, 2,080, 3,080 (25.59, 49.21, 81.89, 121.26) |

| Spindle speed | min-1 | 5,000 | 4,200 |

| Turret | U: V12, L: V8 | U: V12, L: V10 | |

| Motor | kW (hp) | 22/15 (30 min/cont) (30/20) | 22/15 (30 min/cont) (30/20) |

| Machine size (W × D × H) |

mm (in) | 2,950 × 2,176 × 2,080 (116.14 × 85.67 × 81.89) 3,980 × 2,478 × 2,230 (156.69 × 97.56 × 87.80) |

3,570 × 2,310 × 2,200 (140.55 × 90.94 × 86.61) 4,780 × 2,620 × 2,440 (188.19 × 103.15 × 96.06) 6,480 × 2,837 × 2,440 (255.12 × 111.69 × 96.06) 8,405 × 2,471 × 2,309 (330.91 × 97.28 × 90.91) |

| Spec extension | M, 2M, MY, 2MY, W, MW, 2MW | M, MY |

M: Upper multitasking turret, 2M: Upper and lower multitasking turret, Y: Y-axis, W: Sub-spindle