PRODUCTS

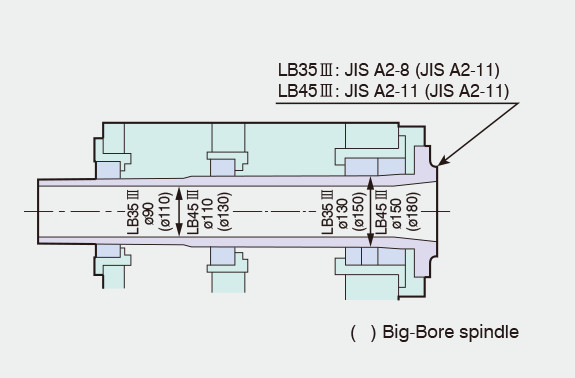

- Rigid spindle for fast, heavy-duty turning

-

- 3-point bearing support for steady, powerful cutting

(double-row cylindrical roller bearings plus highspeed duplex angular contact ball bearings) - Housing cooled for minimal thermal deformation

- Unique labyrinth construction keeps coolant from penetrating spindle bearings

- 3-point bearing support for steady, powerful cutting

- Higher production efficiency with fast machine movement

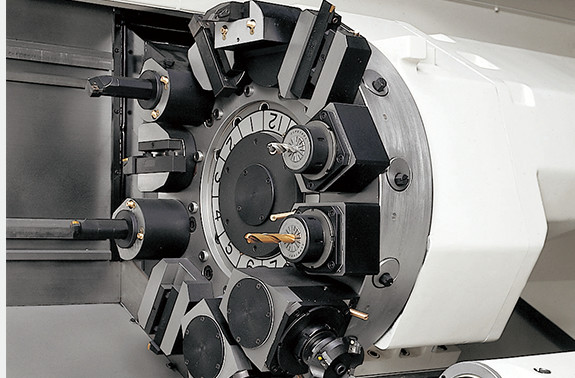

- Multitasking V12 turret gives rise to highly efficient machining

- L (lathe) and M (milling) tools can be mounted in all stations

-

- LB35Ⅲ (M), LB45Ⅲ (M) VDI specs

- Quick change tooling system used

-

-

- LB45Ⅲ (MY) radial tooling specs

- Powerful milling with high power, high torque motor

-

-

- Faster machine movement reduces non-cutting time

-

- Fast turret rotation of 0.3 sec/1 index (LB35Ⅲ)

Rotation speed is also unaffected by unbalanced tooling

* LB45Ⅲ is 0.7 sec/1 index - Further reduction in non-cutting time with high-speed rapid

traverse of X axis: 15 m/min, Z axis: 20 m/min

Uses backlash-free, direct drive mechanism on X axis

- Fast turret rotation of 0.3 sec/1 index (LB35Ⅲ)

-

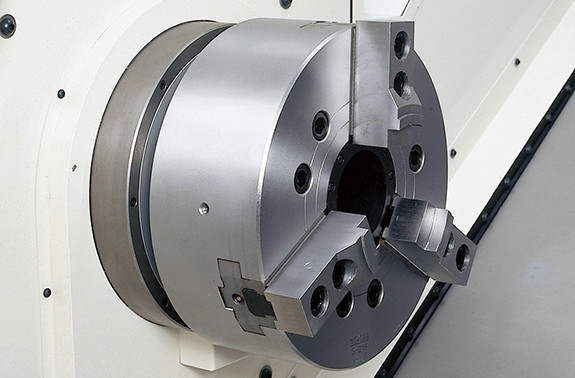

- Powerful clamping to match heavy-duty turning

-

- Big coupling [LB35Ⅲ : ø354 (ø13.94), LB45Ⅲ : ø460 (ø18.11)] for powerful hydraulic clamping on turret

- Large turret but minimal interference

[LB35Ⅲ : 570 mm (22.44 in.), LB45Ⅲ : 700 mm (27.56 in.)] across flats - NC turret with servo motor drive

- Achieves steady machining with high dimensional stability

- Machining dimensional change over time of ø17 μm (LB35Ⅲ actual data)

- In addition to maintaining high dimensional accuracy when room temperature changes, Okuma's Thermo-Friendly Concept provides high dimensional accuracy during machine startup and machining restart.

To stabilize thermal deformation, warming-up time is shortened and the burden of dimensional correction during machining restart is reduced.

- Wide-range of variations

-

-

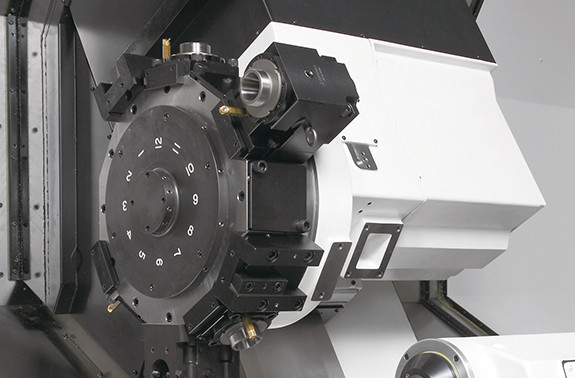

- Process-intensive machining with the Y axis

1-chuck machining even with complexshaped workpieces (LB45Ⅲ MY specs) -

- A wide range of milling based on highly precise, wide-ranging Y axis travel with a double slide system

- Achieves process-intensive machining with 1-chucking

- Process-intensive machining with the Y axis

-

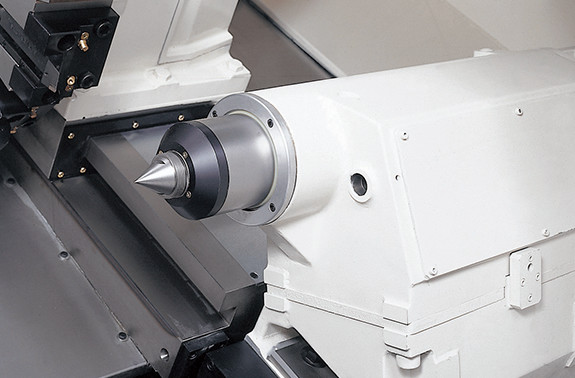

- The best tailstock with built-in center for machining shafts

-

- Highly-rigid built-in center (standard);

Quill diameter LB35Ⅲ : ø120 mm, LB45Ⅲ : ø130 mm

Built-in tailstock MT. No. 5

- Highly-rigid built-in center (standard);

-

Highlighted Specs

| Item | Unit | LB35Ⅲ | LB45Ⅲ |

|---|---|---|---|

| Standard chuck size | in | 12 | 15 |

| Max turning dia | ømm (øin) | 460 (18.11) | 660 (25.98) |

| Max work length | mm (in) | 850, 1,500, 2,000 (33.46, 59.06, 78.74) | 1,000, 2,000, 3,000, 4,000 (39.37, 78.74, 118.11, 157.48) |

| Spindle speed | min-1 | 3,200 | 2,800 |

| Turret | V12 | V12 | |

| Motor | kW (hp) | 30/22 (30 min/cont) (40/30) | 37/30 (30 min/cont) (50/40) |

| Machine size (W × D × H) |

mm (in) | 4,015 × 2,663 × 2,210 (158.07 × 104.84 × 87.01) 4,885 × 2,663 × 2,325 (192.32 × 104.84 × 91.54) 5,910 × 2,663 × 2,325 (232.68 × 104.84 × 91.54) |

4,260 × 3,358 × 2,587 (167.72 × 132.20 × 101.85) 5,760 × 3,358 × 2,617 (226.77 × 132.20 × 103.03) 7,010 × 2,920 × 2,505 (275.98 × 114.96 × 98.62) 8,570 × 3,181 × 2,545 (337.40 × 125.24 × 100.20 |

| Spec extension | M | M, MY |

M: Milling, Y: Y-axis