PRODUCTS

Watch the videos

- LB3000 EX Ⅱ

- Long-term accuracy stability and various process-intensive machining for improved productivity.

- Video Brochure

- Best-selling lathes that achieves improved productivity in high accuracy parts machining.

- High accuracy specifications overall assure

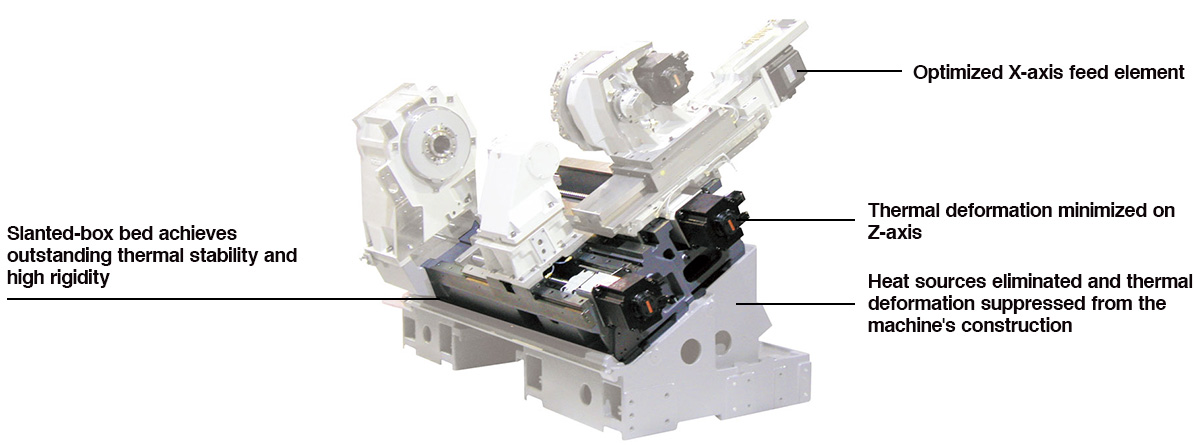

- Slanted-box bed configuration,

with superior construction and rigidity - The primary units of headstock and turret on a box bed are optimally placed for outstanding thermal stability and high rigidity. Exhibits stable machining accuracy even in heavy cutting.

- Thermo-Friendly Concept for unparalleled thermal stability

- Okuma's Thermo-Friendly Concept is used on all the LB EX machines for extraordinary machining accuracy, using our unique machine design and thermal deviation control technology. Outstanding thermal stability in long-time continuous operation, multitasking, front and back side machining with a subspindle, and even Y-axis machining without troublesome compensation or warming up.

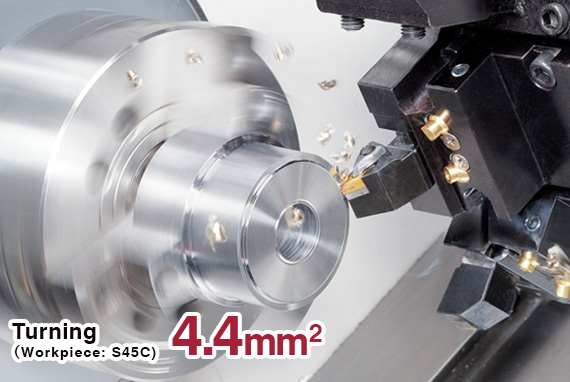

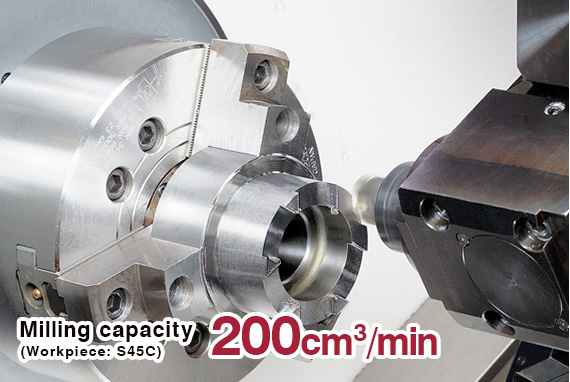

- Improved productivity with highest machining capacity in class

- LB3000 EX Ⅱ actual data

- Rich variation

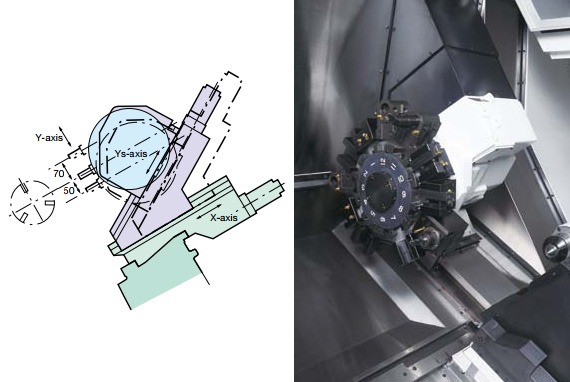

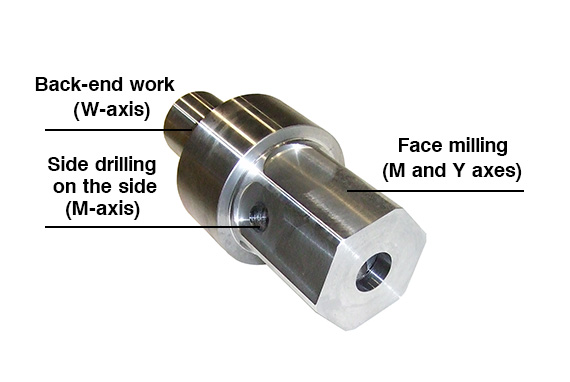

- Complete multitasking with Y-axis functions

One chuck machining even with irregularly shaped workpieces - A variety of milling operations can be accommodated with high-accuracy, wide-range Y-axis travel using a double slide system. Achieves complete multitasking with a single chucking (MY, MYW specifications).

-

-

- Series lineup

- The series has been expanded to four models for selection of the machine size that best suits users' machining work.

-

-

Max turning dia ø430mm

Max work length 500mm -

Max turning dia ø410mm

Max work length 1,300mm -

Max turning dia ø480mm

Max work length 2,150mm -

Max turning dia ø410mm

Max work length 150mm

-

Highlighted Specs

| Item | Unit | LB2000 EX Ⅱ | LB3000 EX Ⅱ | LB4000 EX Ⅱ | LB2500 EX Ⅱ |

|---|---|---|---|---|---|

| Standard chuck size | in | 6 | 8 | 10 | 8 |

| Max turning dia | ømm (øin) | 430 (16.93) | 410 (16.14) | 480 (18.90) | 410 (16.14) |

| Max work length | mm (in) | 300, 520 (11.81, 20.47) | 500, 1,000, 1,300 (19.69, 39.37, 51.18) |

750, 1,500, 2,150 (29.53, 59.06, 84.65) |

150 (5.91) |

| Spindle speed | min-1 | 6,000 | 5,000 | 4,200 | 5,000 |

| Turret | V12 | V12 | V12 | V12 | |

| Motor | kW (hp) | 11/7.5 (20 min/cont) (15/10) | 22/15 (30 min/cont) (30/20) | 30/22 (30 min/cont) (40/30) | 22/15 (30 min/cont) (30/20) |

| Machine size (W × D × H) |

mm (in) | 1,980 × 1,734 × 1,839 (77.95 × 68.27 × 72.40) 2,290 × 1,734 × 1,839 (90.16 × 68.27 × 72.40) |

2,340 × 1,805 × 1,824 (92.13 × 71.06 × 71.81) 3,420 × 2,065 × 1,975 (134.65 × 81.30 × 77.76) 4,344 × 2,185 × 1,975 (171.02 × 86.02 × 77.76) |

3,100× 1,921 × 1,955 (122.05 × 75.63 × 76.97) 4,175 × 2,390 × 2,157 (164.37 × 94.09 × 84.92) 5,515 × 2,505 × 2,005 (217.13 × 98.62 × 78.94) |

1,880 × 1,840 × 1,770 (74.02 × 72.44 × 69.69) |

| Spec extension | M, W, MY, MW | M, W, MY, MW, MYW | M, MY | M |

M: Milling, W: Sub-spindle, Y: Y-axis