- HOME

- NEWSROOM

NEWSROOM

14 Nov 2018

AI for Spindle Diagnosis

Okuma Develops OSP-AI Self-Diagnostics with Spindle Bearings Application

Okuma Corporation has developed a diagnostic function for spindle bearings, and with effective use of deep learning AI, is now incorporated in the OSP-AI Self-Diagnostics technology for machine tools.

Following the diagnostic function for feed axes developed in 2016, a new application for the spindle bearings to perform self-diagnosis is being offered, with features that alert the operator to indications of spindle damage and recommendations for perform predictive maintenance (PdM).

- <Compliance with Production Plans>

- Planning by preparing a maintenance plan in advance according to the state of the spindle bearings allows maintenance work to be carried out without hindering the production plan.

- <Reduction of maintenance cost>

- The cost of maintenance parts is minimized through predictive-maintenance based spindle changes according to spindle bearing conditions.

- <Preliminary preparation is unnecessary>

- It is not necessary to separately prepare measuring instruments such as vibration sensors. It does not require prior diagnosis data collection or threshold settings.

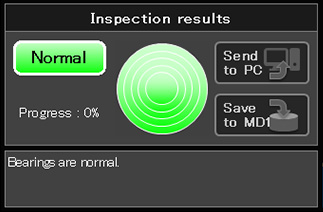

① Easy operation and quick diagnosis

Rotating the spindle at a constant speed and analyzing the measured vibration provides a diagnosis of the bearing condition. Okuma vibration sensors, with high vibration measurement S/N ratios, provide highly reliable data with appropriate signal processing.

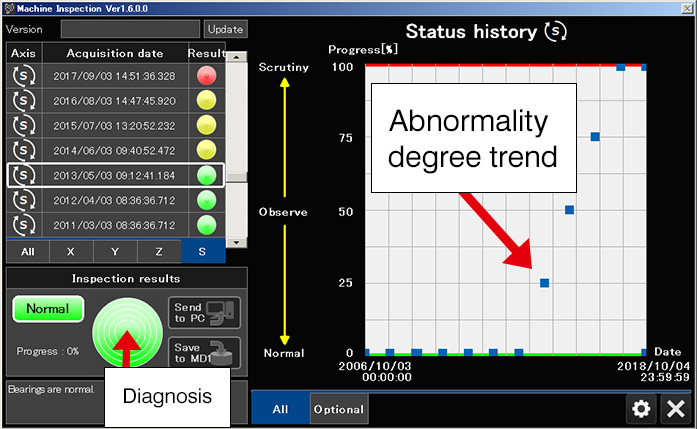

② Visualizing the bearing status, with icons

Depending on the state of the spindle bearings, the color of the icon and the degree of numerical abnormality are displayed on the screen. In addition, by using abnormality trend indicators, it is possible to plan maintenance by predicting abnormality progressions.

-

Diagnosis trends and abnormality degree -

Diagnosis (enlargement)

③ Highly accurate AI - on board

With sophisticated mechanical characteristics and AI (deep learning) technology based on vibration data accumulated so far, highly accurate diagnosis is achieved. Diagnostics technology has increased reliability by accumulating equipment performance records from our own factory. Also, with OSP-AI updates, you can use the latest diagnosis model.

Onboard machine examples

-

MB-5000HⅡ -

MB-46V

OSP-AI Spindle Bearing Diagnostics provides highly reliable self-diagnosis of spindle bearings by utilizing AI technology, so that any operator will easily see the warning signs of spindle damage when they occur and perform cost-saving predictive maintenance.