- HOME

- NEWSROOM

NEWSROOM

22 Oct 2018

Okuma Launches the New "ARMROID Next-Gen Robot System" for Enhanced Automation

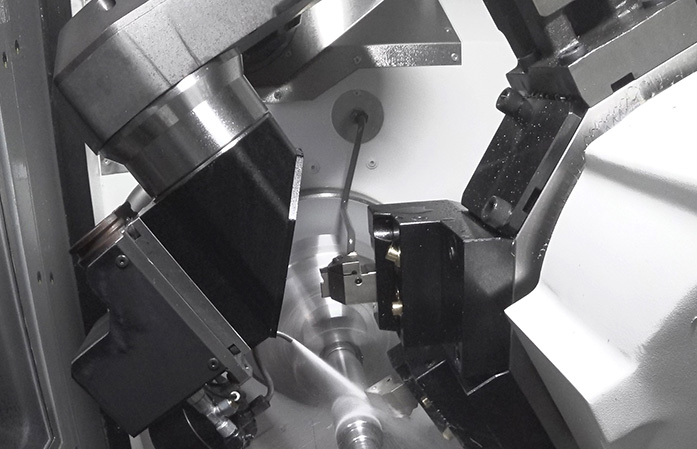

Okuma Corporation has redesigned its LB3000 EXⅡ CNC lathe smart machine with the new ARMROID featuring next-generation robotics, as a fully integrated solution for advance automation applications.

The ARMROID is a "super fusion built-in robot" packaged in the work chamber of a smart machine and lets operators use its "innovative robot operating system" to operate the robot with normal machine tool-like control without requiring teaching, to achieve innovative automation and productivity.

Nowadays, with the decrease in the labor force population, the shortage of human resources has become an issue on the production floor. Furthermore, as efforts to shorten working hours have been promoted through 'work style' reforms, compliance with automation and labor-saving measures are being required not only for large companies but also for small and medium-sized enterprises.

While it is necessary to implement highly automated value-adding operations that reduce operator burden, introducing automated systems take a lot of time and effort, which is preventing the spread of this technology.

Okuma tackled these challenges by developing ARMROID as an easy to set up and use robot system to flexibly handle various workpieces by any operator.

The three major features of the ARMROID Next-Gen Robot System, the world's first fully integrated Robot & Machine, are as follows:

① Significantly improved productivity from a CNC lathe with built-in robot

- Collision-free articulated robot built in the work chamber of a high-tech CNC lathe. Robot motion in the work chamber during machining which is impossible with conventional robots, is possible with the ARMROID

- High level applications support previously provided by expert machinists can be delegated to well coordinated machine and agile-robot operations

- Three types of end effectors are stored, and the robot performs auto end-effector change according to the application

-

Machine & Robot working together

② Supporting zero overtime work. A standalone machine and a robot automated cell can be freely configured according to the job requirement

- For example, the robot can be on standby during the day shift while the operator manually loads/unloads and machines small batch parts, then the robot can handle mass production etc. automatically at night

- Easily switchable from a standalone to a robot cell by simply installing a workpiece stacker

- When used as a single machine, the robot is automatically stored outside the work envelope but inside the machine, and thus be a fully utilized CNC lathe with its large machining area and high machining performance, as is

-

With mobile workpiece stacker installed -

ARMROID when stored

③ Innovation of robot operating. Easy to install and use without teaching or robot integrators

- Since the robot is built in the machine, it is possible to complete the startup of the robot simply by installing the machine itself, and no system integrator is required to separately install the robot

- Robot operating with a new sense of control that can be mastered even without special robotic skills. With Okuma's next-generation control, the OSP-P 300A CNC, robot operating can done as easy as operating the machine

- Robot motion programs can be easily created with interactive computer graphics, eliminating difficult and time consuming programming

With the ARMROID, Okuma offers a completely new robot system that will bring further breakthrough developments in production automation.