- Development of world's first operator support system to automatically find optimum cutting condition

- 23 Oct 2009

Okuma has developed new intelligent technologies to solve a number of problems that occur in cutting operations. One problem is thermal deformation. Our Thermo-Friendly Concept minimizes change in machining dimensions caused by thermal deformation, and gives amazingly stable accuracies. Another problem is collisions and interference in machine operations. Okuma's Collision Avoidance System simulates the movement of structures within the machining chamber and prevents collisions and interference by sensing movements in advance and stopping the machine before collisions occur. Tremendous time reductions are achieved in setup operations, such as in multitasking machines where movements are difficult to predict.

Finally, there is the problem of setting cutting conditions. This is solved by Okuma's third intelligent technology-Machining Navi. To achieve highly efficient machining, the cutting conditions should be set to maximize machine performance. When chatter or other problems occur, however, seemingly endless trial and error work is required to work out the best conditions. With Machining Navi the actual cutting conditions are detected by sensors and the machine finds the best cutting conditions (cutting speed). Using the cutting conditions identified by the machine results in improvements to both machining efficiency and productivity. Improving cutting conditions not only saves time, but provides other benefits including improved machined surface quality as a result of suppressing chatter and other machining vibrations, and extending tool life.

Two specifications are available for Machining Navi.

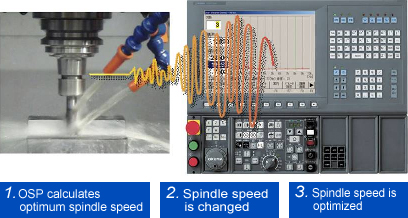

Machining Navi M-i [intelligence]

When Machining Navi is in operation, cutting conditions are detected with sensors, the optimum cutting speed is calculated, and spindle speed is automatically controlled.

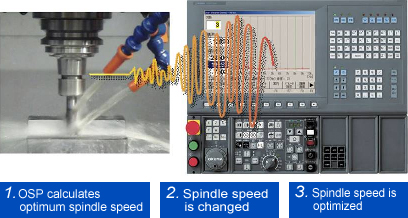

Machining Navi M-g [guidance]

When Machining Navi is in operation, cutting conditions are detected with sensors and the suggested optimum cutting speed is calculated and displayed on the operation panel. The operator can then set the spindle speed according to the display.

Finally, there is the problem of setting cutting conditions. This is solved by Okuma's third intelligent technology-Machining Navi. To achieve highly efficient machining, the cutting conditions should be set to maximize machine performance. When chatter or other problems occur, however, seemingly endless trial and error work is required to work out the best conditions. With Machining Navi the actual cutting conditions are detected by sensors and the machine finds the best cutting conditions (cutting speed). Using the cutting conditions identified by the machine results in improvements to both machining efficiency and productivity. Improving cutting conditions not only saves time, but provides other benefits including improved machined surface quality as a result of suppressing chatter and other machining vibrations, and extending tool life.

Two specifications are available for Machining Navi.

Machining Navi M-i [intelligence]

When Machining Navi is in operation, cutting conditions are detected with sensors, the optimum cutting speed is calculated, and spindle speed is automatically controlled.

Machining Navi M-g [guidance]

When Machining Navi is in operation, cutting conditions are detected with sensors and the suggested optimum cutting speed is calculated and displayed on the operation panel. The operator can then set the spindle speed according to the display.