- HOME

- Technology & Solutions Case Studies

- Tamatec Co., Ltd

Case Studies

—Why Okuma was chosen

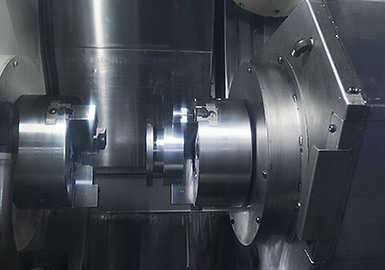

From aerospace, medical, and optical components to semiconductor

manufacturing equipment, the MULTUS achieves both micron-level precision machining and high-efficiency production.

Tamatec Co., Ltd

- Industry

- Precision parts machining

Challenges at the manufacturing site

When using a lathe and machining center to manufacture components,

we wanted to reduce time used for setup and machining preparation,

and eliminate accuracy variations during setup.

We manufacture precision parts for industries such as aerospace, medical and optical equipment, and semiconductor manufacturing equipment. Many of these parts have complex geometries and are made from difficult-to-machine materials such as inconel and titanium alloys. All have strict dimensional tolerances and require to be machined within a 10-micron accuracy range.

Before installing the MULTUS BⅡ series, we machined these parts using both NC lathes and machining centers. Accuracy becomes difficult to maintain when using several machines to machine a single component, but we made sure we always met each industries’ quality assurance standards.

However, in order to grow our business, we needed to improve productivity by shortening lead time used during for precision machining processes.

Yet, this presented several challenges. Time and labor required for setup changes and preparation between machining processes had to be reduced. Yet at the same time, consistent levels of precision had to be maintained during the machining of difficult-to-machine materials.

The Okuma machine selected to solve these challenges

Decisive factor for installation

We selected the MULTUS BⅡ series equipped with sub-spindle specification because of its high mechanical rigidity, precise control of thermal displacement, built-in collision avoidance function, and reliable operability.

To address the challenges we faced, we concluded that the best solution would be to shorten lead times by using multitasking machines to achieve proccess integration.

Among the available options, we concluded that the MULTUS B300Ⅱ (sub-spindle specification) was the best choice in terms of fundamental performance and compatibility with workpiece sizes which ultimately lead to its installation.

The main decisive factor for choosing the machine was its high rigidity. This was an essential requirement for machining difficult-to-cut materials with high accuracy and speed.

Another key factor was the Thermo-Friendly Concept, a thermal displacement control technology that ensures stable machining dimensions.

Although we operate using a two-shift operation schedule to keep utilization rates of machinery as high as possible, machine operations stop between 4:00 a.m. to 8:00 a.m. due to an opening between shifts. However, the MULTUS B300Ⅱ is capable of maintaining stable machining accuracy even after a cold start at the beginning of the day shift. This applies even during seasons when outside temperatures are extreme.

When machining difficult-to-cut materials, cutting tools are subjected to high loads, resulting in quicker replacement cycles. One superb feature of the machine is that tool life for each indivudual tool can be managed on the OSP system.

Additionally, we had experience of using Okuma’s NC lathes, so we were confident that it would not be diffficult to learn how to program and operate an Okuma multitasking machine. (Hirotaka Ishikawa)

Third Manufacturing Section

Effectiveness of machine after installation

All machining processes can be completed with a single multitasking machine, resulting in approximately 30% improvement in productivity.

Both high quality and high productivity can be achieved while reducing labor.

When processes are divided between a NC lathe and a machining center, significant time and effort are required for tasks such as dimensional inspection, setup changes, and workpiece cleaning.

With the MULTUS B300Ⅱ (sub-spindle specification), parts that previously required four processes on two separate machines can now be completed in just two processes on a single machine due to the abiltiy to transfer workpieces between spindles. This has eliminated the need to handle work-in-progress workpieces between machines and has improved the overall production flow.

In addition, because there is minimal phase error during transfer, positioning jigs are no longer necessary. Also, issues that occurred during setup changes—such as scratches, dents, and the need to remachine due to size errors—have been drastically reduced.

As a result, we have been able to significantly reduce tasks that were required between processes, resulting in a productivity improvement of approximately 30%. All this is done while maintaining micron-level machining quality.

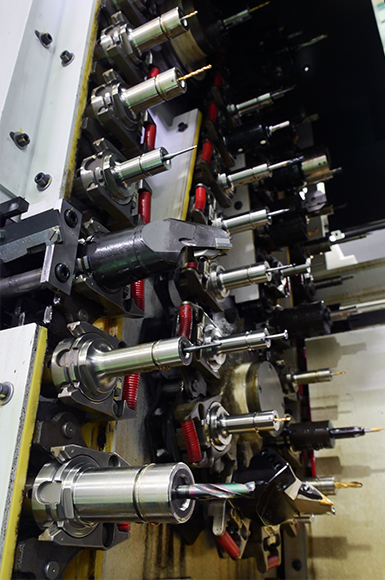

We have eight MULTUS machines machining parts ranging from ø10 to 50 mm, and every two machines are operated by a single operator.

Even when machining complex parts that require various cutting and drilling operations, the MULTUS can be left unattended for approximately 30 to 60 minutes. During that time, operators can focus on preparing for the next process or conduct quality checks, which helps reduce the workload for operators managing multiple machines.

Precision parts with strict accuracy requirements that only Tamatec can manufacture.

Capable of machining difficult-to-machine materials with high accuracy and ensuring stable production of tight-tolerance parts.

There was a motor shaft job that our competitors had refused because they could not meet its strict accuracy requirements. However, we took the job and were able to succesfully meet the various tolerances that were required for the workpiece.

Also, another difficult component is optical lens barrels. These have strict geometric tolerances, such as keeping a concentricity of ø0.01 for threading from end-to-end of the barrel. If this tolerance is not met, the optical axis of the lens will not align properly and result in a defective product. However, we were easily able to achieve a concentricity of ø0.01.

In addition, the MULTUS B300Ⅱ (sub-spindle specification) features a highly rigid milling spindle, allowing it to machine tough-to-cut materials such as Inconel and titanium alloys with ease. Even at high spindle speeds.

The machine also offers exceptional repeatability, enabling stable machining of precision components with tight tolerances—such as medical device parts—with dimensional accuracy in the 10-micron range.

Even if several machining processes are involved, the 60-tool ATC specification allows optimal tool to be used during each proccess.

All eight MULTUS machines that were installed by 2024 are equipped with a 60-tool ATC specification.

12-turret lathes lack sufficient tooling capacity, requiring the workpiece to be re-clamped during machining—resulting in longer cycle times and reduced machining accuracy.

On the other hand, machining can always be performed using the optimal tool with a 60-tool ATC machine. This enables high-accuracy machining even for parts that require various processes.

In addition, when machining difficult-to-machine materials—where cutting edges wear quickly and frequent tool changes are necessary—the tool life management function allows easy monitoring of each tool’s usage and replacement timing, providing significant support in tool management.(Hiroki Watanabe)

The first machine ever installed is still in operation, proving the high rigidity and long-term accuracy stability of Okuma machines when doing high-accuracy machining of difficult-to-cut materials.

Outlook to the future

We are considering the introduction of bar feeders and ARMROID systems to enable unmanned operation.

We also plan to take on the challenge of doing simultaneous 5-axis machining and the manufacturing of highly complex components, such as camshafts

Currently, the loading and unloading of workpieces is performed manually by operators. However, we are considering the installation of MULTUS machines equipped with bar feeders and the built-in robot system ARMROID to automate this process to further enhance productivity.

We also aim to expand our business by taking on the challenge of doing simultaneous 5-axis machining and the manufacturing of highly complex components, such as camshafts.

(Executive Vice President Takeshi Yoshida)

A single machine can produce finished products, eliminating work-in-progress workpieces.

Customer Information

Tamatec Co., Ltd

(Iwase-gun, Fukushima Prefecture)

- Website

- https://www.tamatec.net/

In 1996, Tamatec split from its parent company Ishikawa Factory and became an independent company. The company manufactures optical and communications devices, components for semiconductor manufacturing equipment, and automotive prototype parts, among many others. All this is done with the numerous 5-axis machining centers and multitasking machines installed in their factory. In 2008, the company acquired JISQ9100 certification—a quality assurance standard for the aerospace industry—and began receiving orders to manufacture aircraft engine parts. Tamatec demonstrates its unique technology for high-accuracy machining of difficult-to-cut materials—such as nickel alloys, titanium alloys, and Inconel—with micron-level accuracy. In the 2010s, the company was responsible for machining the Small Carry-on Impactor (SCI) device that was equipped on the asteroid probe Hayabusa2. Recognized as a Company Driving Regional Growth in Fukushima Prefecture by the Ministry of Economy, Trade and Industry (METI).