PRODUCTS

The best machine for automated production lines

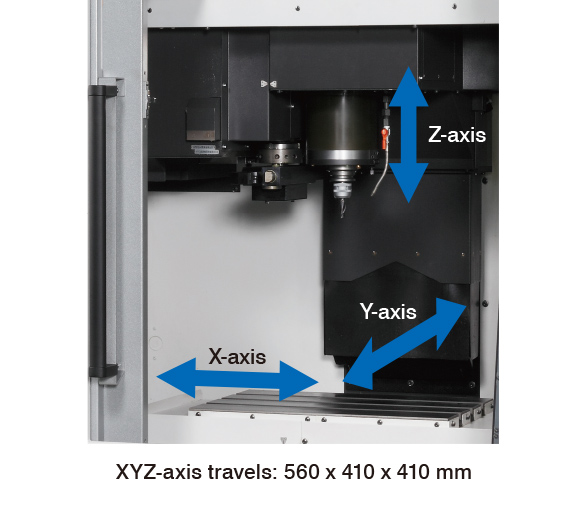

Space-saving, with large work envelope

- Space-saving machine

-

- Large work envelope

-

Highly productive and efficient, high quality cutting

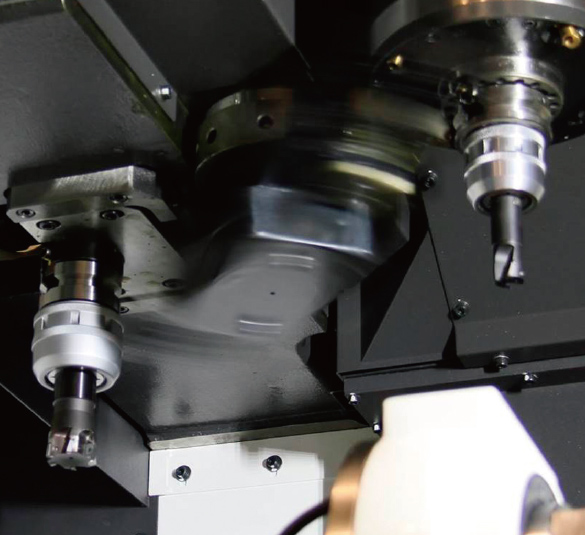

- X, Y, Z axis slideways

- The slideway on each axis is a highly rigid box way, enabling high vibration absorbance, high quality machining.

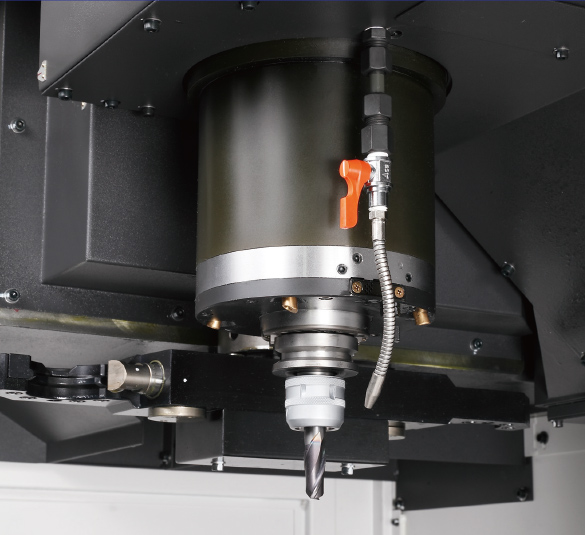

The superb maintainability of the 44V Ⅱ also provides long-term product assurance for the customer. - VAC integral motor/spindle

- Spindle is supported by ceramic angular bearing and roller bearing, for low heat generation and low vibration even with long and high-speed operation.

An integrated motor used for the drive also gives quiet, smooth turning increments from low to high speeds. - High cutting stability with use of dual contact spindle

High productivity with reduced cutting and non-cutting times

Shorter cutting times

- Spindle speed 12,000 min-1

- Spindle output 15/11 kW (25%ED/cont)

- Max torque 73.4 N-m

- Cutting federate X-Y-Z axis Max 20,000 mm/min

Reduced non-cutting times

- Rapid traverse X-Y-Z axis 50 m/min

- Rapid traverse acceleration 1.0 G

- Spindle startup 1.0 sec/10,000 min-1

- ATC time T-T/C-C 0.9 sec/3.1 sec

- ATC magazine indexing 1.2 sec (16-tool magazine/half cycle)

Highlighted Specs

| Item | Unit | MILLAC 44V Ⅱ | |

|---|---|---|---|

| Standard | 2APC | ||

| Table size | mm (in) | 630 × 400 (24.80 × 15.75) | (Pallet) 400 × 400 (15.75 × 15.75) |

| Spindle speed | min-1 | 12,000 | |

| Tool storage | tools | 16 | |

| Motor | kW (hp) | 15/11 (25% ED/cont) (20/15) | |

| Machine size (W × D × H) |

mm (in) | 1,600 × 3,440 × 2,400 (62.99 × 135.43 × 94.49) |

1,600 × 3,550 × 2,600 (62.99 × 139.76 × 102.36) |

| CNC | OSP / FANUC | ||