PRODUCTS

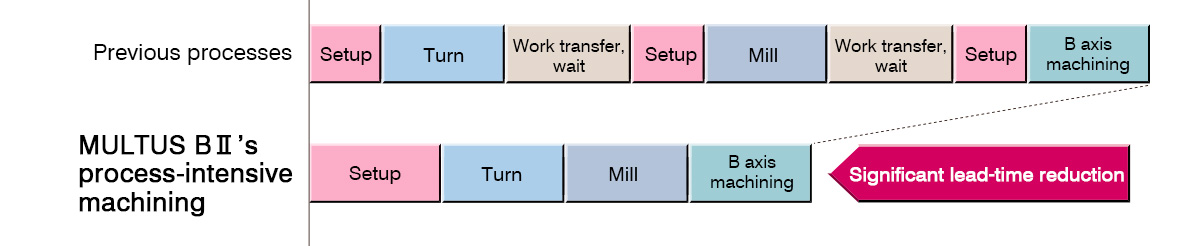

- Multitasking is easier than ever

- Lathe, vertical or horizontal machining center,

and material handling operations consolidated into one machine... - Shorter deliveries and more effective use of floor space, plus fewer setups and operation with fewer workers, result in better process control and greatly reduced total cost.

-

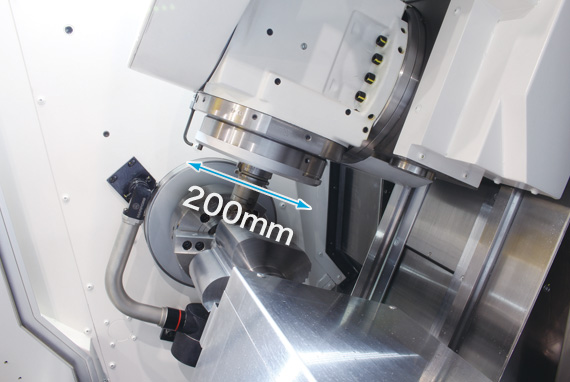

- Both high machining capacity and

large machining area on a compact machine - Large work envelope

- Y-axis travel

- MULTUS B200Ⅱ:160mm /

MULTUS B250Ⅱ:200mm /

MULTUS B300Ⅱ:160mm /

MULTUS B400Ⅱ:230mm -

-

MULTUS B250Ⅱ -

-

-

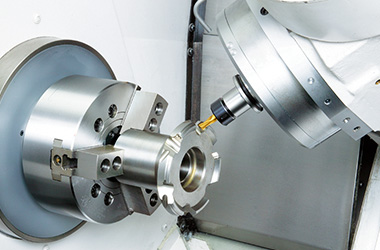

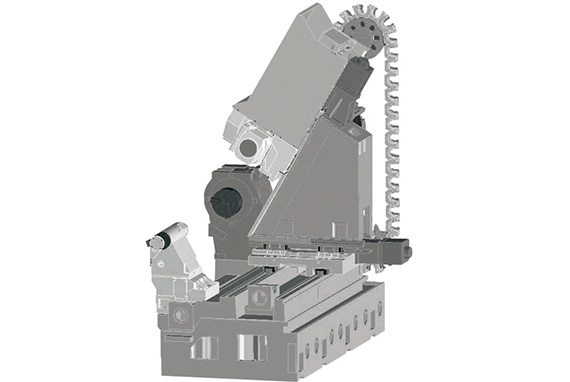

- Highly rigid bed and guideways

-

- Stable machining achieved with wide, rigid bed.

- Featuring X-Y-Z-axis roller guides designed with high rigidity, antiwear, and vibration damping.

Roller guide rigidity 2.6 to 3.0 times that of ball guide.

-

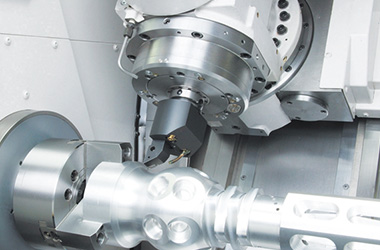

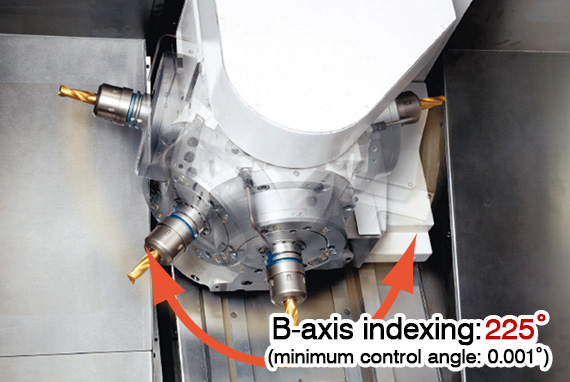

- Powerful, compact turret

-

- Compactness and high output with PREX motor

- Highly rigid roller bearings for live tool spindle (front bearings)

(for MULTUS B300Ⅱ / B400Ⅱ)

Motor output

MULTUS B200Ⅱ/

MULTUS B250Ⅱ12,000min-1:12kW 20,000min-1:9kW* MULTUS B300Ⅱ 6,000min-1:11kW 10,000min-1:16kW MULTUS B400Ⅱ 6,000min-1:14kW 10,000min-1:20kW *HSK-A63

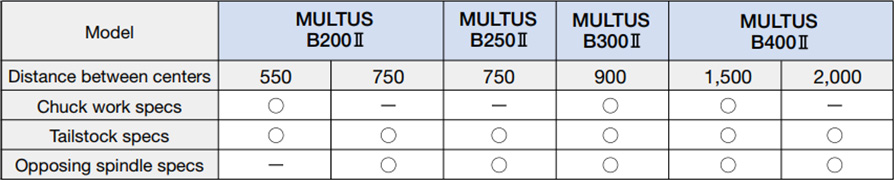

- Spec extensions to handle all kinds of workpieces

- Abundant spec extensions

-

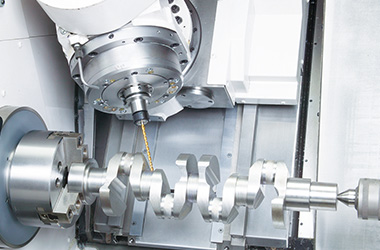

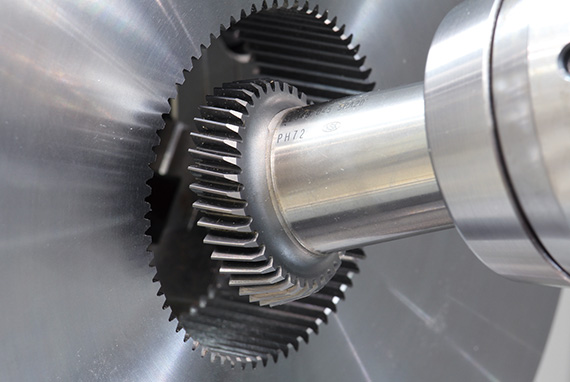

- High accuracy gear machining with a multitasking machine

Gear Machining Package (Optional) -

Gear machining that previously required complex programming can now be done with ease. With GMP, simply input the tool type, gear data, and cutting conditions. Programming time is reduced to about one-tenth that of manual input. Process-intensive machining is achieved, including the gear machining that used to be done on expensive special-purpose machines.

Skiving(OD/ID splines)

Highlighted Specs

| Item | Unit | MULTUS B200Ⅱ | MULTUS B250Ⅱ | MULTUS B300Ⅱ | MULTUS B400Ⅱ |

|---|---|---|---|---|---|

| Standard chuck size | in | 6 | 8 | 8 | 10 |

| Max machinig dia | ømm (øin) | 600 (23.62) | 600 (23.62) | 630 (24.80) | 710 (27.95) |

| Max work length | mm (in) | 550, 750 (21.65, 29.53) | 750 (29.53) | 900 (35.43) | 1,500, 2,000 (59.06, 78.74) |

| Spindle speed | min-1 | 6,000 | 5,000 | 5,000 | 3,800 |

| Tool storage | tools | 20 | 20 | 20 | 20 |

| Motor | kW (hp) | 11/7.5 (20 min/cont) (15/10) | 15/11 (20 min/cont) (20/15) | 15/11 (20 min/cont) (20/15) | 22/15 (50% ED/cont) (30/20) |

| Machine size (W × D × H) |

mm (in) | 3,080 × 2,210 × 2,582 (121.26 × 87.01 × 101.65) 3,620 × 2,210 × 2,582 (142.52 × 87.01 × 101.65) |

3,620 × 2,210 × 2,582 (142.52 × 87.01 × 101.65) |

4,035 × 2,257 × 2,587 (158.86 × 88.86 × 101.85) |

5,750 × 2,693 × 3,000 (226.38 × 106.02 × 118.11) 7,050 × 2,693 × 3,137 (277.56 × 106.02 × 123.50) |

| Spec extension | W | W | W | W |

W: Opposing spindle