PRODUCTS

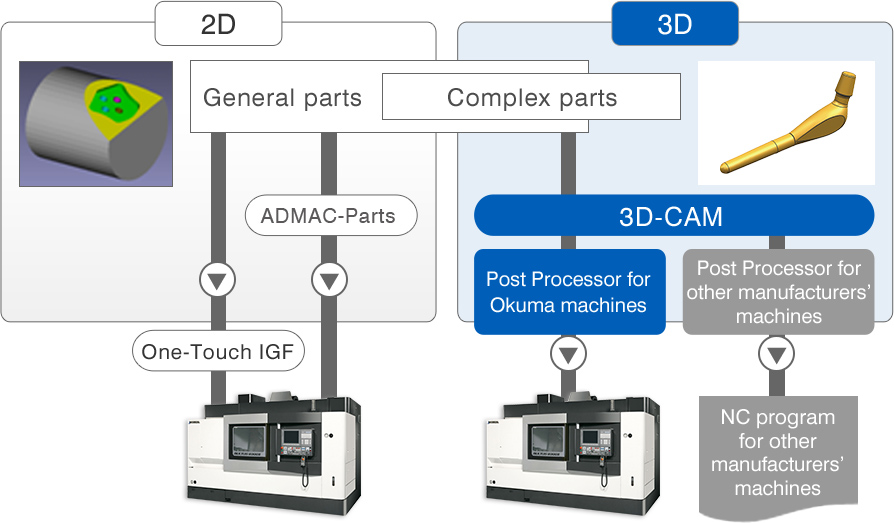

Use of 3D-CAD data in manufacturing plants is spreading for the purpose of promoting advance verification in upstream processes or coordinating product data across multiple departments. At the same time, multitasking machines are used more and more in parts machining, which is the ultimate objective of manufacturing, to accommodate diverse part shapes and forms of production such as process-intensive machining. Simple NC programming with 3D-CAM is needed.

To support the 3D-CAM activities of our customers, Okuma, in cooperation with major CAM makers, has developed a Post Processors*1 for Okuma machines that can be used globally.

A programming solution that can be used immediately after installation

With this jointly developed system, major 3D-CAM makers raise the reliability of the Post Processors for Okuma machines that they provide to distributors in all countries and regions. This Post Processors eases the burden of customers and can be used immediately as a Post Processors necessary for machine operation.*2

*1 : Post Processors transforms the cutting path generated by CAM to an NC program matched to the machine configuration and controller.

*2 : Please contact CAM manufacturer for details on compatible machine models and other information.