- HOME

- Technology & Solutions Premium Solutions

- ECO suite plus

Technology Premium Solutions

ECO Idling Stop

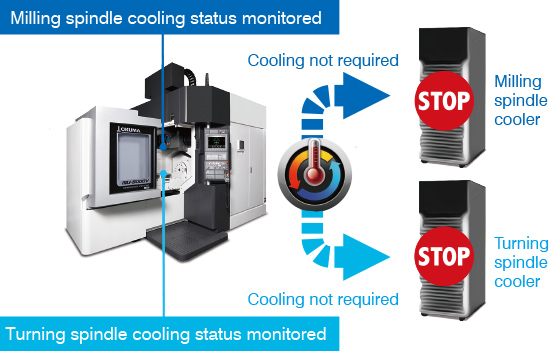

Ensure accuracy and actively turn off unnecessary peripherals

All auxiliary equipment when not needed (most of factory power consumption), can be turned off.

The ECO Idling Stop button enables diligent idle stop operations even during machining and maintenance work.

The cooling system necessary for maintaining accuracy uses Thermo-Friendly Concept technology, and the machine itself decides when to cool and stop idling while maintaining high accuracy.

With ECO suite plus, the machine automatically detects the operating status, eliminating the need to push buttons while reducing carbon dioxide emission as much as possible without operator awareness.

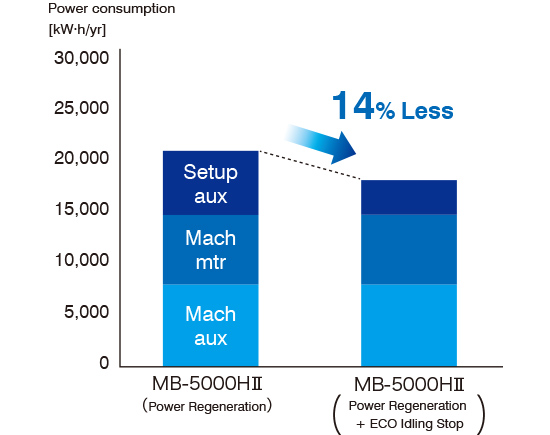

- [Calculations]

- Horizontal Machining Center MB-5000HⅡ 50% utilization (8 hr/da, 20 da/mo, 1 yr)

- Assuming 50% of setup and standby time used ECO Idling Stop.

- Workpiece: Aluminum casing

- Average load: 30% rating

- Calculated from measured regenerative power

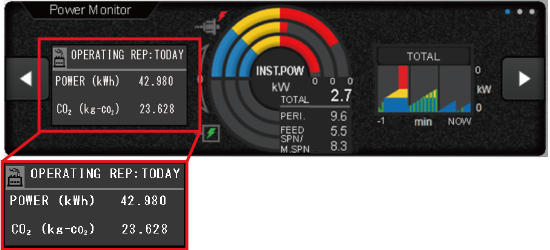

ECO Power Monitor

Evaluating energy savings and analyzing areas of reduced energy

Making it possible for the OSP control to analyze the operating status of each device.

-

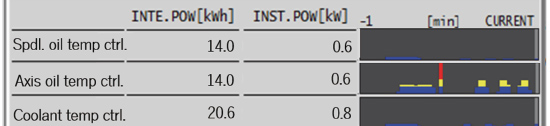

① Check carbon dioxide emissions on the spot

With ECO suite plus, you can also check the power consumption of each device.

-

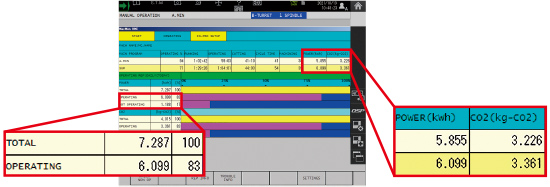

② Simultaneously records operating status and carbon dioxide emissions

With ECO suite plus, recording carbon dioxide emissions for each device, and data output is possible.

-

③ Analyze carbon dioxide emissions and improve machine tool operation

With ECO suite plus, not only the display on the machine but data analysis for each device is also possible on a PC, to see a more detailed carbon dioxide emission analysis.

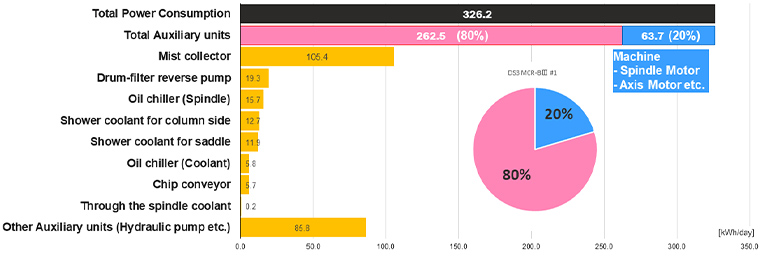

MCR-BⅢ at DS3 Energy Consumption

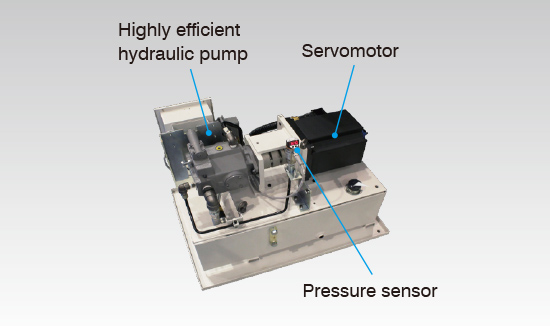

ECO Hydraulics (option)

Highly efficient hydraulic power pack reduces power consumption

- Conventional hydraulic unit

- MB-4000H actual data:

840 W

- ECO Hydraulics

- 25min-1

260W

[Pressurized]

ECO Operation (option)

Peripheral equipment runs only when needed

By using only the required peripherals (chip conveyor, mist collector), energy-saving operations that also maintain high productivity are possible.

ECO suite plus enables more detailed tuning of operations to thoroughly support carbon dioxide emission reduction activities that do not reduce productivity.