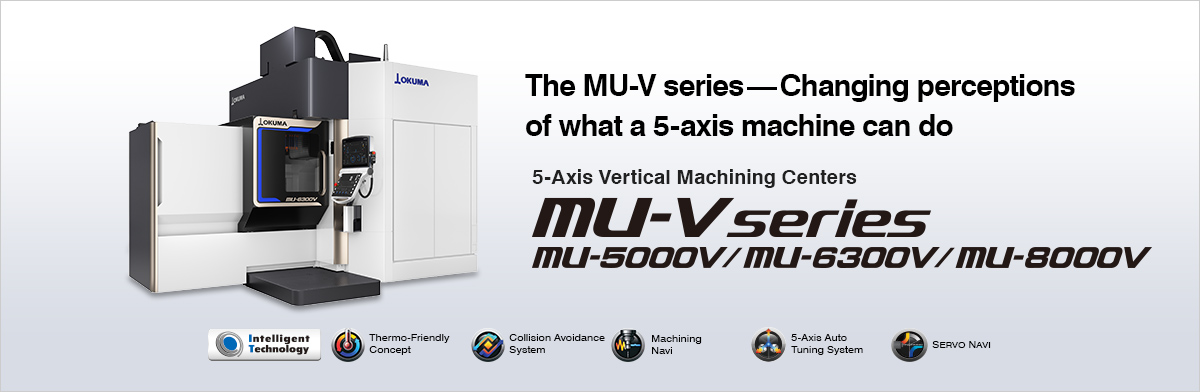

PRODUCTS

Watch the videos

- MU-6300V-L

- MU-6300V-L with all new design and equipped with the new generation CNC "OSP-P500".

See the MU-6300V-L machining a polygonal chamber for semiconductor manufacturing equipment.

- Innovations in volumetric accuracy

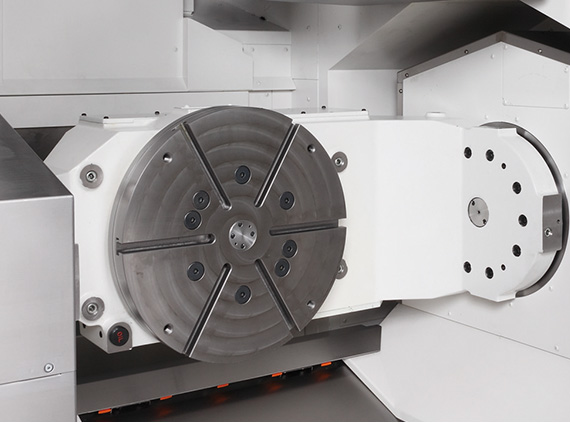

- Highly rigid trunnion table supports high-accuracy 5-axis machining

-

High quality machined surfaces with the high following of 5-axis machining

●Highly-rigid trunnion table supports both ends

●With ball-screw cooling (Std), reduced following error is achieved while maintaining highly accurate machining.

The indexing accuracies that take 5-axis machining to higher accuracies (MU-5000V Actual data)

●Indexing accuracy

- ・A-axis indexing accuracy/Indexing return accuracy: ±0.68 sec/±0.40 sec

- ・C-axis indexing accuracy/Indexing return accuracy: ±0.78 sec/±0.14 sec

●Fast operation

- ・A-axis/C-axis 90°clamp/unclamp indexing time: 1.0 sec/1.2 sec

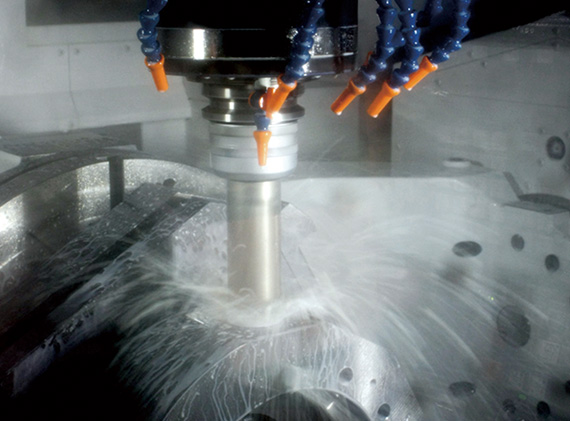

- A 5-axis machine that really cuts

- Beyond the limits of conventional 5-axis machining

Highly efficient machining with amazing machining capacity - MU-5000V, MU-6300V Actual data ([ ]: MU-6300V specs)

-

- Face milling capacity: 504cm3/min (S45C)

-

●ø80 face mill 8 blade (coating)

- Spindle speed: 895min-1

- Cutting speed: 225m/min

- Feedrate: 2,250mm/min

- Cut width × infeed: 56 × 4mm

-

- End milling capacity: 672cm3/min (S45C)

-

●ø20 roughing end mill 7 blade (carbide)

- Spindle speed: 4,000min-1

- Cutting speed: 251m/min

- Feedrate: 4,800mm/min [2,800mm/min]

- Cut width × infeed: 7 × 20mm [12 × 20mm]

- Process-intensive machining with turning capacity that approaches that of a lathe

- Turning capacity: 3mm2 (S45C)

-

- Machining dia: ø164mm [ø250mm]

- Cutting speed: 130m/min (table rotation: 252min-1)

- Feedrate: 0.6mm/rev

- Infeed: 5mm

※ The above are actual examples. Your results may vary due to differences in specifications, tooling and cutting conditions.

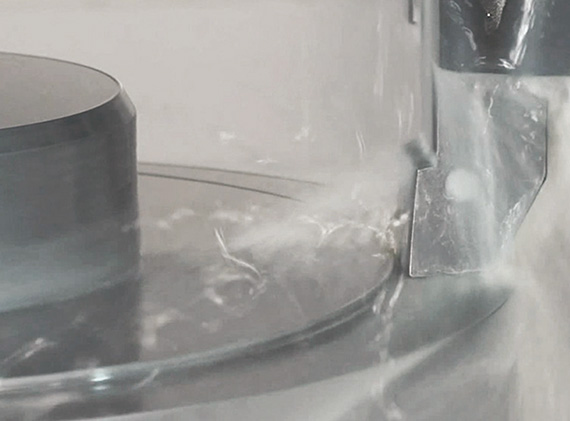

- Get a real sense of the good visibility and

operability required in 5-axis machining - Superb operator access to the machining chamber

-

-

-

Structure allows easy tool edge confirmation during setup and machining

●Best table, spindle, and operation panel layout in terms of operability

-

Large step platform for easy working

●Operating stress reduced with large platform so that operator does not have to worry about footing

-

Large window for good visibility in machining compartment

-

-

-

-

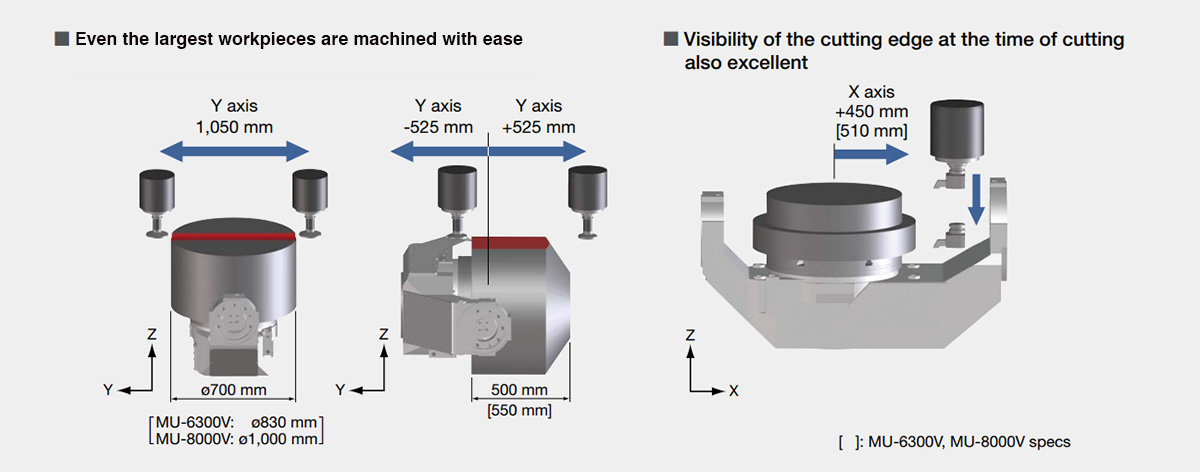

- Large machining range; tools can be changed with

trunnion still in swing position - The tool reaches the end of the workpiece even with the table at various inclination angles, enabling wide-range 5-axis machining.Tools can be changed with the trunnion still in a swing position, leading to reduced cycle times and higher machining accuracies.

-

Highlighted Specs

| Item | Unit | MU-5000V | MU-6300V | MU-8000V |

|---|---|---|---|---|

| Table size | mm(in) | ø500 (ø19.69) | ø630 (ø24.80) | ø800 × 630 width (ø31.50 × 24.80) |

| Spindle speed | min-1 | 10,000, 6,000 | 10,000, 6,000 | 10,000, 6,000 |

| Tool storage | tools | 32 | 32 | 32 |

| Motor | kW(hp) | 11/7.5 (10 min/cont) (15/10) | 11/7.5 (10 min/cont) (15/10) | 11/7.5 (10 min/cont) (15/10) |

| Machine size (W × D × H) |

mm(in) | 3,995 × 2,750 × 3,435 (157.28 × 108.27 × 135.24) |

4,850 × 2,990 × 3,525 (190.94 × 117.72 × 138.78) |

5,280 × 2,990 × 3,625 (207.87 × 117.72 × 142.72) |

| Spec extension | L | L | L |

L: Turning specification