PRODUCTSNEW PRODUCTS

Achieve both high-accuracy 5-axis machining and decarbonization (energy saving). Support factory decarbonization.

Both stable accuracy and reduction of carbon dioxide emissions

The workpiece machining accuracy changes significantly due to machine ambient temperatures, heat generated from in-machine components and cutting. The idea behind Okuma's Thermo-Friendly Concept is simply "accepting" these temperature changes so that high accuracy can be achieved in normal factory environments without requiring special customer preparations. Maintaining excellent accuracy stability is possible without relying on excessive ambient temperature control from machine cooling systems and factory air conditioners.

The "ECO suite plus" retains the concept of achieving both high machining accuracy stability and energy savings (less carbon dioxide emissions) achieved by the Thermo-Friendly Concept and the "ECO suite" that was put into practical use in 2014. It is an energy-saving system with enhanced high-accuracy/-productive functionality and advanced eco-friendly support.

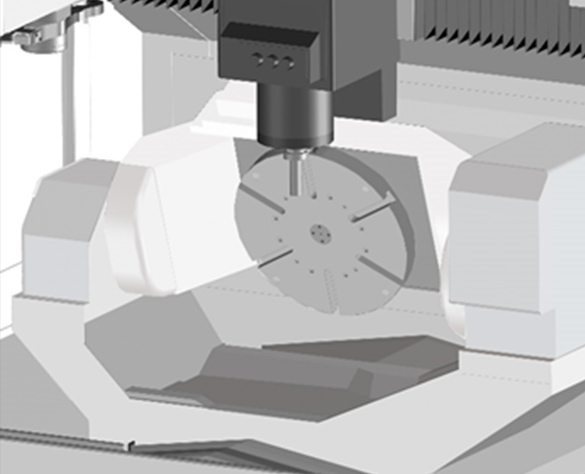

A large machining area capable of handling a variety of

workpieces with the smallest possible floor space

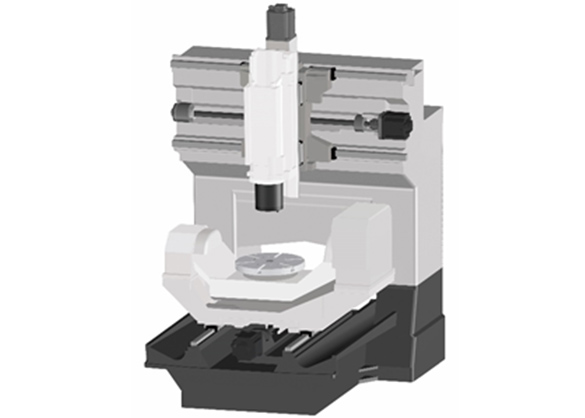

A compact machine can be installed in most spaces.

The space required is similar to that of a vertical machining center, so that even small and medium-sized factories can install it easily.

- A compact machine supporting a maximum workpiece diameter of ø700 mm that can be installed in most spaces.

- Only requires 8.2 m2 of floor area (down 25% from conventional models)

Has the largest machining area in its class that can handle workpieces with

a maximum diameter of ø700 mm with ease.

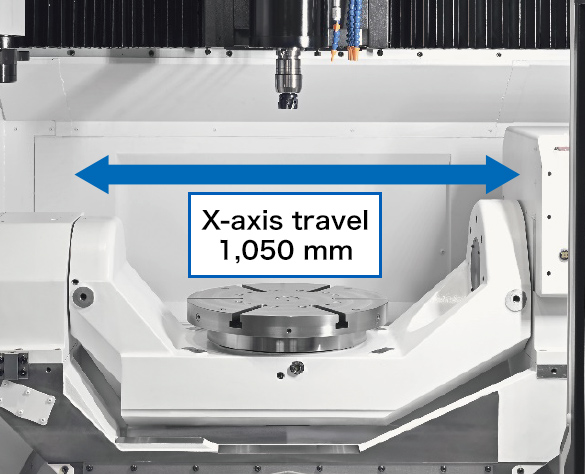

- X-axis travel: 1,050 mm

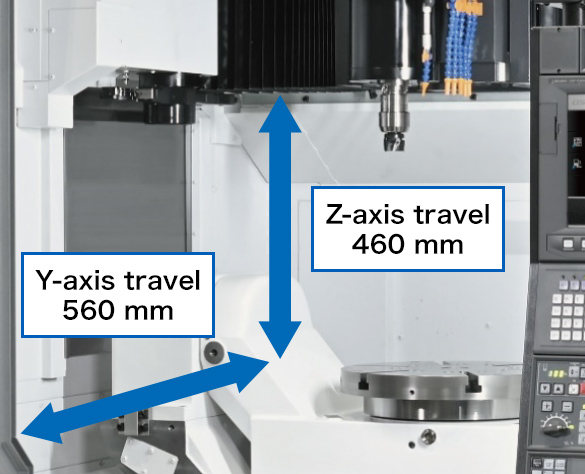

- Y-axis travel: 560 mm

- Z-axis travel: 460 mm

High machining capacity and high-rigidity machine construction

that makes highly efficient production possible

Capable of heavy machining of a wide variety of materials and has a powerful standard spindle that reduces machining time.

- Maximum spindle speed 15,000 min-1, maximum output 22 kW

- Maximum cutting capacity 672 cm3/min

(Material to be cut: S45C steel, end mill machining)

Highly rigid machine construction has been adopted to stably support heavy cutting loads.

Highly rigid double-column construction adopted from proven double-column machining centers.

A high-rigidity trunnion table supported on both ends provides strong support for workpieces up to a maximum of 400 kg.

double-column machining centers.

Made to be as easy to use as possible to minimize the burden on operators.

5-axis machining with the same ease of use as a vertical machining center.

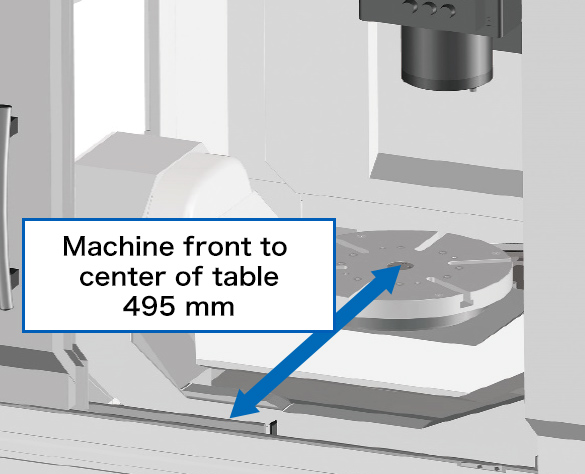

A highly visible trunnion table that makes it easy to see workpieces while they are being machined.

A user-friendly machine construction that allows comfortable setup work.

- Good approachability that makes it easy to reach tables.

- The distance from the front of the machine to the center of the table is 495 mm.

Highlighted Specs

| Item | Unit | GENOS M560V-5AX |

|---|---|---|

| Table dimensions | mm (in) | ø500 (19.69) |

| Max workpiece dia | mm (in) | ø700 × 500 (27.56 × 19.69) |

| Spindle speed | min-1 | 15,000 |

| Tool storage | tools | 48 |

| Motor | kW | 22/18.5 (10 min/cont)(30/25) |

| Machine size (W × D × H) |

mm | 2,515 × 3,263 × 3,045 (99.02 × 128.46 × 119.88) |