- HOME

- Technology & Solutions Okuma Smart Factory

- The Next-Generation Intelligent CNC OSP suite [OSP-P300A]

Technology & Solutions Okuma Smart Factory

Machine shops get top priority with easy-to-use OSP controlAn Intelligent CNC designed

for the Shop Floor

Smart factories are using advanced digitization and networking (IIoT) in manufacturing to achieve enhanced productivity and added value.

The OSP has evolved tremendously as a CNC suited to advanced intelligent technology.

Okuma’s new control uses the latest CPUs for a tremendous boost in operability, rendering performance, and processing speed.

The OSP suite also features a full range of useful apps that could only come from a machine tool manufacturer, making smart manufacturing a reality.

Huge boost in machining process efficiency with a sense of creative operation, changing the working day of machine operators

Operators involved in the machining of complex parts are surrounded by checklists, work orders, process sheets, user’s manuals, and more. They often need to go to offices or design rooms for clarifications or to get more documents.

An environment that would allow operators to easily access required data or information on the CNC screen and let them use the tools they prefer without stress would greatly increase efficiency in sophisticated multitasking or 5-axis machining operations.

The OSP suite next-generation CNC pursues this ideal and will transform your shop floor into a place of true creation.

Features you wanted Loaded with OSP suite apps!

Okuma made these features a reality by building on its machining expertise, based on requests received from customers in the machine shop. These features are filled with intelligence that enhance the "strength in the field" that the CNC control can accomplish because they are created by the premier machine-tool manufacturer.

Increase utilization with advance tool preparation

Tool Life Predictor (Optional)

When the number of operations is input, whether any tools will reach their lifespan and the number of parts that can be machined is predicted. Advance tool preparation becomes possible and machine down time can be reduced.

Stores operation sheets and uses them as a knowledge bank

Operation Sheet Creation (Optional)

Operation sheets are automatically created from part programs. Stored performance data can be used as built-in know-how for quick machining preparations of repeat jobs.

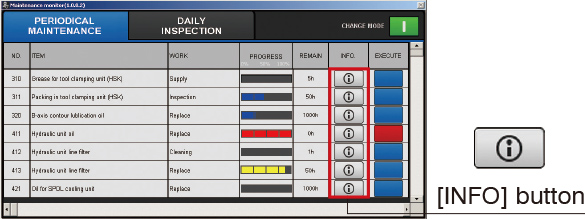

Routine inspection support

Maintenance Monitor

The Maintenance Monitor displays items for inspections before starting daily operation and regular inspections and the rough estimate of inspection timing. Touching the [INFO] button displays the PDF instruction manual file of relevant maintenance items.

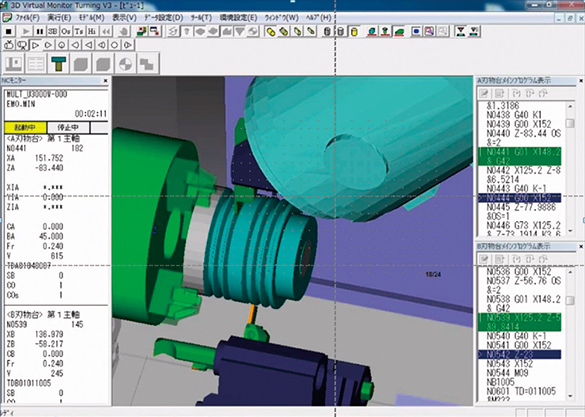

Remote PC screen displayed on the OSP

Remote Desktop

Simple access to a 3D Virtual Monitor that is operated from an office computer. Machining can be confirmed with a 3D image before the start of the job.

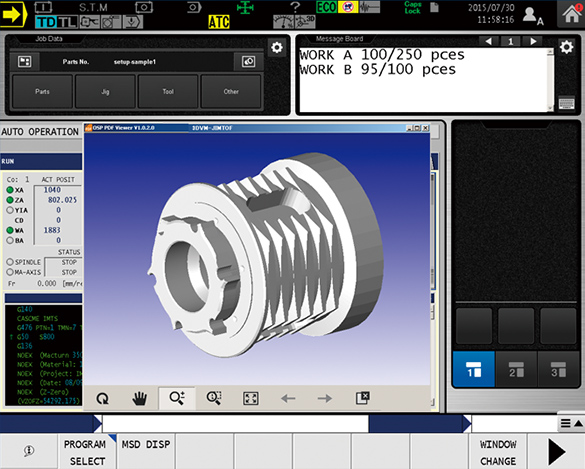

Paperless shop floor

Job Data

Machining instructions are digitized.

Shapes can be confirmed with 3D images of the part drawing to be machined for smooth set-up operations.

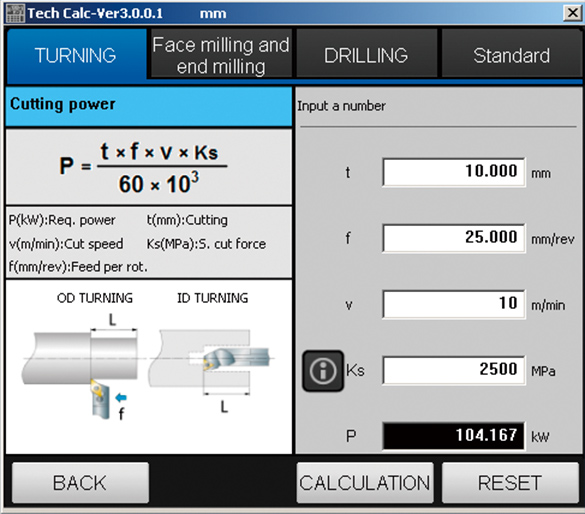

Support in calculating cutting conditions

Tech Calc

Calculations and information for cutting conditions that require special know-how are displayed on-screen for quick task completion.

Digital clipboard

White Board

Handwritten messages traced on the touch panel are displayed and sent to night shift workers.

Keyboard typed in messages can

also be relayed.

Increased productivity through visualization of motor power reserve

Spindle Output Monitor

Monitoring operating status even when away from the machine

E-mail Notification

Comments displayed — work easier, faster

Common Variable Monitor

Automatic saving of recorded alarms

Screen Capture

Easy programing without keying in code

Scheduled Program Editor

With smartphone-like touchscreen operations Stress-free "suite operation"

Highly reliable touch panel suited to shop floors.

The layout on the operation screen can be arranged to suit operator preferences,

customized according to needs of operators with all levels of experience.

Up to three suite apps needed for a job can be constantly displayed.

Suite apps for the things the operator wants to see or know can also be started with a single touch.

Each process can now be performed with much greater efficiency.

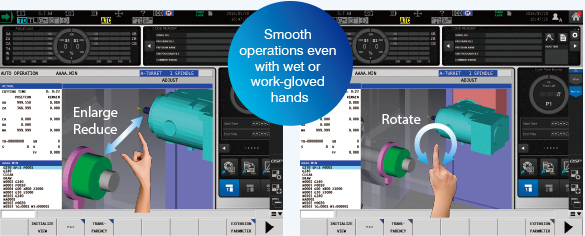

Smooth, comfortable operation

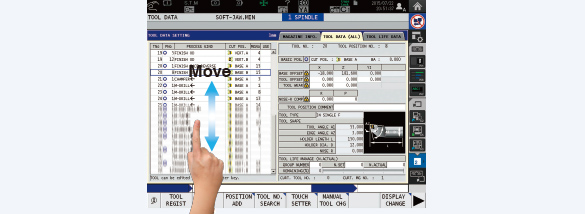

Improved rendering performance and use of a multi-touch panel achieve intuitive graphical operation. Moving, enlarging, reducing, and rotating 3D models, as well as list views of tool data, programs, and other information can be accomplished through smooth, speedy operations with the same feel as using a smart phone.

Momentum scrolling for finding target items with ease

When scrolling rapidly through screens, motion continues even after the finger releases the screen. This can make it easier to find a target item in a list view of items, such as tools or program files.

Functions accessible using multi-touch panel operations:

Collision Avoidance System, Easy Modeling, Advanced One-Touch IGF, PDF/STL Viewer, data views, program-file list-view operations and program editing operations.

![The Next-Generation Intelligent CNC OSP suite [OSP-P300A]](/english/smart-factory/osp-suite/images/osp-suite/p_main_pc.jpg)