Case Studies

Supplying the finest press dies to the world's car manufacturers

with the high-quality, high-efficiency machining of Okuma's double-column machining centers

GOITECH IND. CO., LTD.

Located in Siheung, which is about 30 km southwest of Seoul, GOITECH has a significant presence in the automobile press die industry. Its main products include a wide variety of dies used to manufacture ultra-high-tensile steel parts, such as interior and exterior door frames and engine hoods, and interior structural parts. Their high-accuracy finish is highly acclaimed by well-known finished car manufacturers in South Korea and other countries.

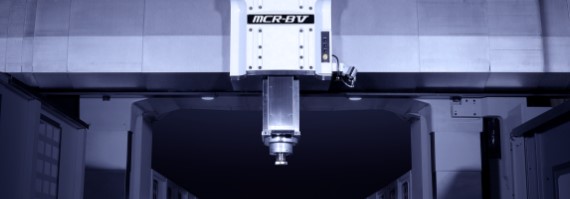

Okuma's double-column machining centers are unrivaled in die machining

due to their unique Intelligent Technologies

The Thermo-Friendly Concept minimizes thermal deformation caused by changes in room temperature or heat generated by machines during long periods of machining through machine design and control technology. It was applied to large double-column models before it was applied to other models. This produces outstanding dimensional stability and reduces the time required for polishing and die matching after machining, and this has significantly shortened the lead time for the production of large dies.

Furthermore, SERVONAVI optimized servo control technology maximizes the acceleration capabilities of machines and reduces cycle times while maintaining machining accuracy. This makes it easy to maintain and improve dimensional accuracy and surface quality in die machining, which involves frequent repetitions of acceleration and deceleration.

GOITECH's factories also make full use of these Intelligent Technologies to help improve quality and productivity.

Customer Information

GOITECH IND. CO., LTD.

- World Headquarters / Plants

- 145, Emtibeuibuk-ro, Siheung-si,

Gyeonggi-do, 15119 Korea

- Established

- 1991

- President and CEO

- Jung-Teak, Suh

- Employees

- 110

- Phone

- 82-31-432-6252