High-efficiency grinding of quartz glass

POINT 01

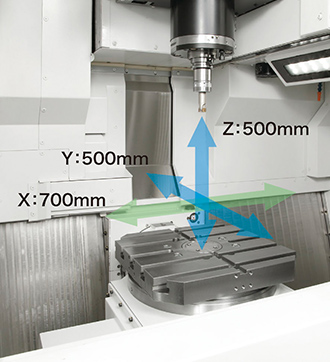

- Increasing machining efficiency with slope machining utilizing a 5-axis machining center

-

- Achieves high-efficiency grinding with C-axis continuous rotation specifications

- Keeping inclined surface of the workpiece horizontal by tilting the table, making multi-step machining of the inclined surface unnecessary, to improve machining efficiency

Quartz ring machining (similar workpiece)

POINT 02

- High-efficiency cutting and a difficult-to-cut material machining package to reduce maintenance

-

- Packaging specifications required for difficult-to-cut material machining

- C-axis continuous rotation specifications

- Reducing the time and effort required for maintenance with dustproof specifications, enhancement of chip treatment,

and a filtering system

Enhancing chip cleaning power

POINT 03

- Improving area productivity with an extremely narrow machine

-

- Handling a maximum workpiece diameter of ø600 with a machine body width of 1,586 mm*1

Achieves the highest area productivity in its class

*1: With the difficult-to-cut material machining package specifications, a peripheral device is added to the width above

- Handling a maximum workpiece diameter of ø600 with a machine body width of 1,586 mm*1