Chambers

Vacuum chamber parts of semiconductor manufacturing devices

Material: SUS304

Efficient machining from block materials

POINT 01

- Improvement in efficiency of roughing and high-speed finishing with a high-output spindle

-

- Main spindle capacity: 10,000min-1 No.50 (option)

- Suitable for a wide range of processes from heavy-duty cutting to high-feed machining

High-efficiency machining with a power spindle

(sample workpiece)

POINT 02

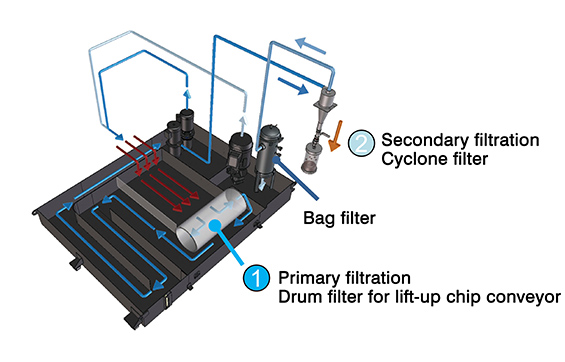

- Enabling machining for a long time without the intervention of a worker, with an enhanced in-machine chip discharge ability

-

- Preventing problems with chips during operation with a simple in-machine cover structure and enhancement of coolant washing

POINT 03

- Reducing the burden of tank cleaning with a sludgeless tank

-

- Collecting sludge efficiently with three types of filtration systems

- Sludge removal rate: 99%

- No tank cleaning for 3 years (Okuma equipment actual data)