Okuma Technology Premium Solutions

Process-intensive 3D gauging for

multitasking machines

multitasking machines

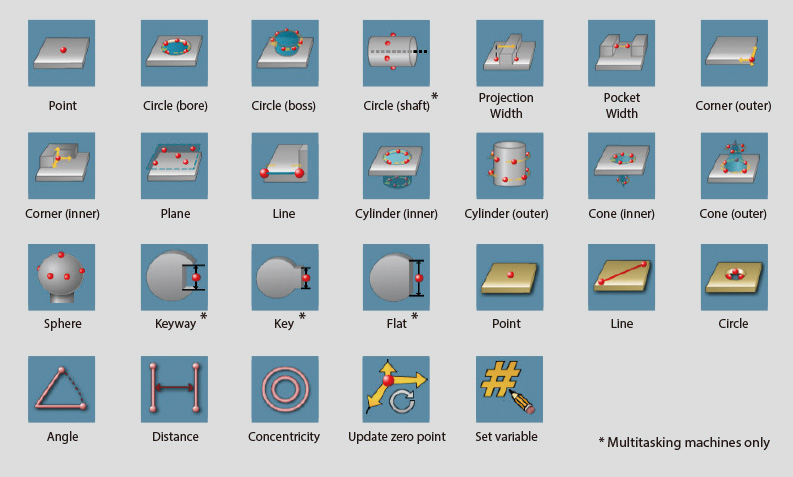

Measure shapes on the machine to calculate geometric error and virtual positions.

Intuitive teaching operations make it easy to create a measurement program.

- Production floor issues

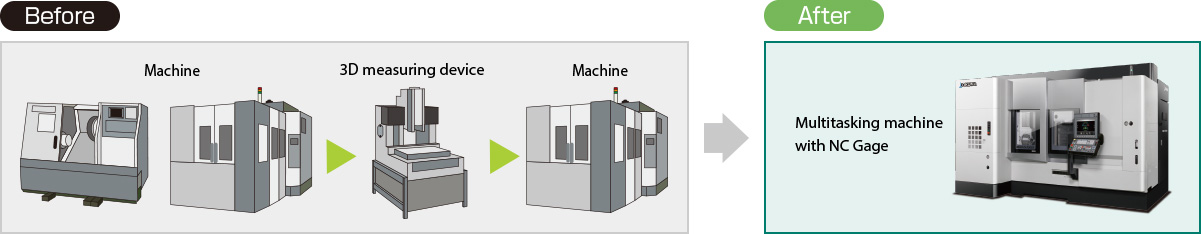

- Setup changes required for 3D measurement

-

- ・Workpiece removal, transport, re-mount, etc; troublesome.

- ・Workpiece angles need to be changed to measure slopes.

- ・Must make measuring programs with difficult macros.

- User benefits

- Lead-time drastically reduced without changeovers

-

- ・Mount/dismount, moving fixtures for measuring devices not required.

- ・Measure surfaces and slopes without changing workpiece posture.

- ・“Easy Operation” allows you to create measuring programs.

On-machine 3D measuring reduces setup changes

- Auto programming

- Easy to create programs to measure and calculate geometric errors and workpiece positions.

- Reduced setups

- Geometry pass/fail can be determined on-machine.

Easy measuring with intuitive Teach-In programming

Teach-In helps make various measuring programs without using difficult macros.