PRODUCTS

Productivity is higher with process-intensive machining

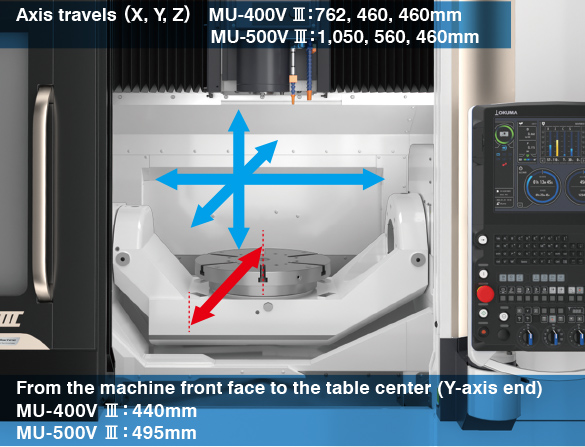

5-Axis Vertical Machining Center achieves high accuracy and decarbonization with space-saving and a large machining area

Achievement of both high accuracy and high productivity with emissions reduction and energy saving

We chose the name “Green-Smart Machine” for our machine tool that achieves high accuracy and reduced energy consumption autonomously and realizes high productivity. With Green-Smart Machines, we will contribute to the solution of social issues faced by the global manufacturing industry, together with our customers.

High machining capacity with highly rigid structural design to handle a wide range of machining from high-mix, low-volume production to mass production

Large machining area

Even though it is as space-saving as a vertical machining center, MU-500V has the largest machining area among the machines in the same class. It can also handle with high efficiency 5-axis machining of large workpieces with a diameter as large as 700 mm.

Machining capacities (actual data)

Spindle 15,000 min-1 (No.40) wide-range spindle (option) Workpiece material: S45C

| Tool | Spindle min-1 |

Cutting m/min |

Feed rate mm/min |

Width mm |

Depth mm |

Chips cm3/min |

|---|---|---|---|---|---|---|

| ø80 face mill 8 blades | 895 | 225 | 3,000 | 56 | 3 | 504 |

| ø20 roughing end mill, 7 flutes | 4,000 | 251 | 8,400 | 4 | 20 | 672 |

| ø63 insert drill | 720 | 143 | 108 | - | - | - |

| Tap M30P3.5 | 255 | 24 | 893 | - | - | 72% (Spindle load) |

OSP

A next-generation CNC that makes customer manufacturing DX (digital transformation) a reality

Next-generation CNC

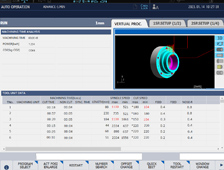

Improved productivity and stable production

As Your Single Source for merging M-E-I-K (Mechanics - Electronics - IT - Knowledge) technologies, Okuma offers this CNC to build an advanced “digital twin” that faithfully reproduces machine control and machining operations and creates new value.

In addition, the product helps improve productivity and achieve stable production, featuring ease of use that allows customers to use their machining know-how. Additional features are: control technology that achieves high-speed and high-accuracy machining, energy-saving solutions that achieve both high accuracy/productivity and eco-friendliness, and robust security functions to protect against the increasing threat of cyber attacks.

- Faithful digital reproduction of machines and processing Ground-breaking concept of a digital twin

- Realizing high-speed and high-accuracy machining Leading-edge machining

- Novice-friendly smart operation Innovative operability

- Reducing environmental impact Energy-saving solutions

- Increasing cyber resilience Robust security

-

Home screen -

Virtual machining -

Preparation of the process chart -

Operation with the process chart -

MacMan plus

Highlighted Specs

| Item | Unit | MU-400V Ⅲ | MU-500V Ⅲ |

|---|---|---|---|

| Table size | mm (in) | ø400 (ø15.75) | ø500 (19.69) |

| Spindle speed | min-1 | 8,000 [15,000, 20,000, 35,000] | |

| Tool storage | tools | 20 [32, 48, 64, 98, 132, 166, 200, 234, 268] * | |

| Motor | kW (hp) | 11/7.5 [22/18.5, 30/22, 15] (15/10 [30/25, 40/30, 20]) (10 min/cont) |

|

| Machine size (W × D × H) | mm (in) | 2,160 × 2,783× 2,946 (85.04 × 109.57 × 115.98) |

2,515 × 3,231 × 3,045 (99.02 × 127.20 × 119.88) |

* ATC with 64 or more tools will use matrix method and tools will have fixed addresses

[ ] : Option