Surprised by the MB-V’s high dimensional stability, experiencing the evolution of the Thermo-Friendly Concept in the MU-V machines

The first Okuma machine we installed was the MC-5VA vertical machining center in the mid-1980s. A malfunction occurred (when we were still new to machine tools) but Okuma’s applications team responded seriously to our request for assistance. I liked their seriousness, and since then we have actively brought in Okuma machines, built on a relationship where we can order without hesitation and mutually enhance our technologies.

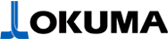

Even so, I was surprised when we installed the MB-56V and MB-66V equipped with the Thermo-Friendly Concept for the first time. There was almost no machining step error between square surfaces, and it was easy to narrow down the required compensation value. When assembling 10 thin weatherstrip molds, if the cutting accuracy is poor, even skilled workers will have to take considerable time to make corrections and adjustments, but that work has drastically decreased. Customers have also responded with “What excellent workmanship! The molds are awesome!” Eventually we ended up installing, only from the MB-V series, 13 machines. It can be said that it is a famous model that has changed die/mold manufacturing.

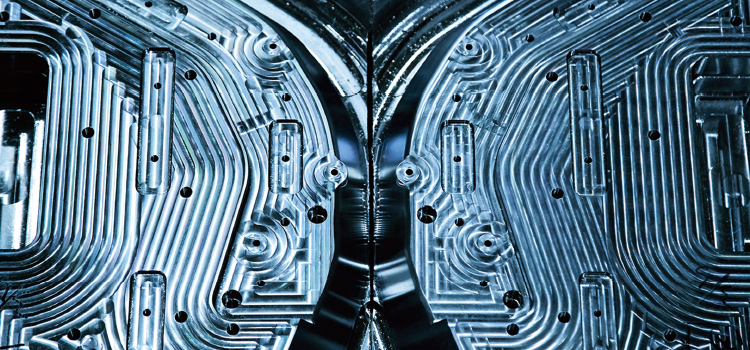

In recent years, four machines, the MU-6300V and MU-8000V 5-axis vertical machining centers, have become a major strength. Comparing the first and last workpieces in the mass production of molds, the dimensional accuracy is stable, and a wide range of machining can be completed with one chucking. Operator work efficiency is good, and it is liked by trainees from abroad who say they’re easy to use.

| Head office | 54-2 Haru Tatetsukuri, Kiyosu City, Aichi Pref, JapanWEB SITE |

|---|---|

| Incorporated | 1972 |

| Business | Rubber molds, weatherstrip mold design and production, resin mold design and production, surface treatment (MS Processing), golf club design and production |

Yukihiro Sakoda