All machines are Okuma made— the ones with Thermo-Friendly Concept meet tight tolerance requirements

Our company is divided into 3 teams: lathe, machining center, and multitasking machine, that work together to finish the job. We have a lineup of Okuma machines which includes the large V100R vertical lathe, LB45II, LU45II, LB35III, LB3000 EX, and LB4000 EX horizontal lathes, MB-46VAE, MB-66VA VMCs, and the MA-500HB, -600HB HMCs, etc. The multitasking machines we use are the MULTUS B300, B400 and B750.

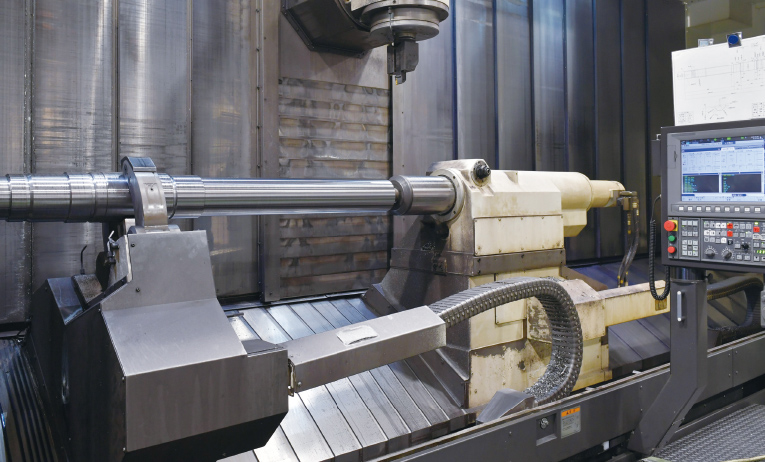

A typical workpiece requires is precision machining of ball screw shafts of various sizes and ball assembly nuts. Ball screws convert motor rotation into linear motion and perform high-precision positioning and feed control, and are widely used in machine tools, industrial robots, factory automation, and semiconductor manufacturing equipment. Tolerances are tight for the parts that affect the performance of the final product. With shaft grooving at a full length of 3,100 mm and ø140 mm, the groove travel per motor revolution is 40 mm, and the tolerance is 40.003 mm. Grooves cannot be formed at one time and will thermally expand as the cutter is reciprocated many times.

Previously, corrections were made by a lathe, but after installing the MULUS B750 intelligent multitasking machine, getting the required dimensional accuracy became possible just by numerical input, and we were able to considerably reduce the workload through “process-intensive” turn/mill operations. Although thermal control is more difficult for larger machines, the dimensional stability of the Thermo-Friendly Concept is outstanding even when machining shafts from 3,000 to 4,000 mm, and with the Machining Navi function, chatter has also been controlled to support our precision machining requirements.

When machining workpieces 3,000 to 4,000 mm long, using Machining Navi is a must.

| Head Office | 11-3 Ogatayama, Tsuru City, Yamanashi Pref (Ohara Industrial Park), Japan |

|---|---|

| Incorporated | 1964 |

| Business | Precision machine parts, vehicle parts, machining of IT-related parts (especially large precision parts) |

Yoshikazu Shirakawa