- HOME

- NEWSROOM

NEWSROOM

12 Nov 2018

Introducing the STANDROID Next Generation Robot System

to Promote Automation and 'Work Style' Reforms

Okuma Corporation has developed a next generation robot system called STANDROID which can facilitate the introduction of automated systems.

Conventionally, the machine tool and the robot are operated by different control systems, and the robotic automation system was built by an expert system integrator.

Designed to be a "teaching-less" robot, the innovative STANDROID is equipped with a global-first Robot Operating System (ROS) that enables the operator to handle it safely and with the same ease of operating a machine tool.

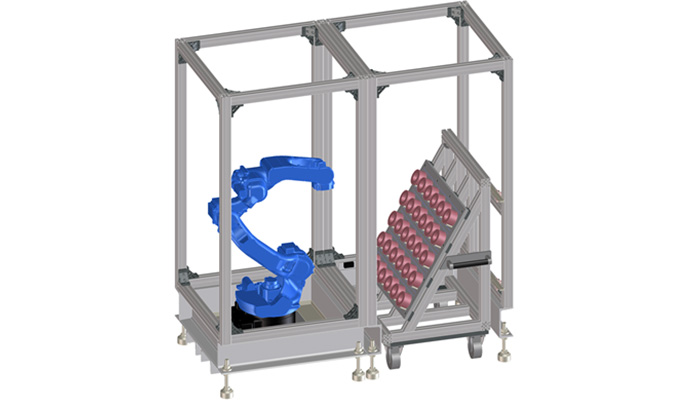

The Compact Automated Cell (CAC) package includes all the equipment required to easily build and implement an automated space-saving system without relying on system integrators.

① Robot packages make system setups easy, and will innovate productivity

Packaged sets of system building equipment are available. Signal confirmations of the robot have already been done at the time of shipment. When installing, just setting up the integrated robot/workpiece stacker CAC and connecting the power supply and network cable will complete the setup. Setting up an automated system easily, without a system integrator, is possible.

-

5-axis machining center + STANDROID -

VMC + STANDROID

② Innovating robot operating. Intermediate teaching point settings not required

Operating the robot is easy, just like operating a machine tool, without expert robot operating experience.

When changing the workpiece type, the operator can easily set robot motions without knowing the robotic programming language. Lengthy preparation and confirmation periods will be greatly reduced, as part of the effort to use of the robot for high-mix, low-volume (HMLV) production applications.

- Even if the workpiece or mounting position is changed, the part program can be changed with only a setting change.

- STANDROID can be manually operated with the pulse handle or the jog feed button of the machine tool.

-

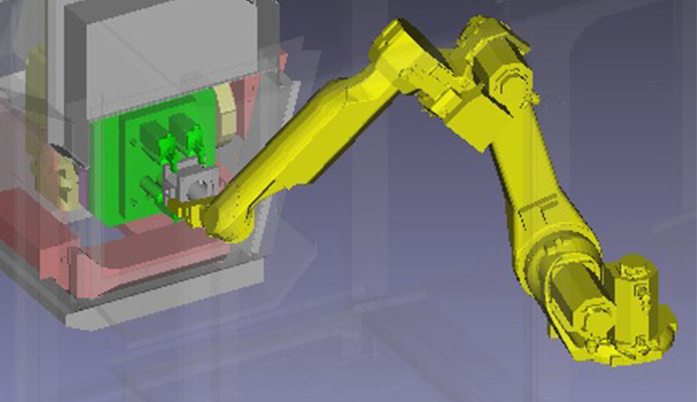

3D simulation to check collisions in advance

(MU-S600V + STANDROID)

③ Collision-Free Control assures safe and smooth operations in a compact automated cell

Simply inputting the start and end points of motion by interacting with the CNC operation panel, Collision-Free Control automatically creates the shortest non-interfering routes in a tight space for easy operating confirmation.

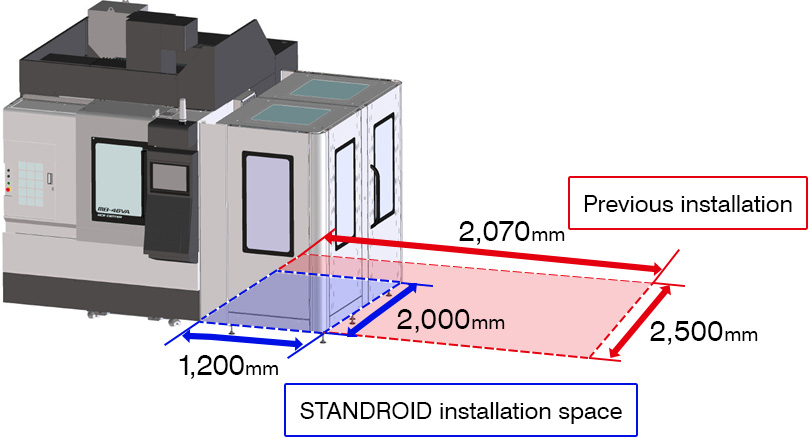

The robot, workpiece stacker, and other related equipment are minimally packaged in a space of only about 2 pallets.

Conventionally, the need for space for the movable range of the robot that was surrounded by a safety fence, is no longer needed.

-

Mobile compact workpiece stacker -

Workpiece stacker for long-run continuous operations

With effective use of the STANDROID Next-Generation Robot System, Okuma is strongly in support of productivity innovations and 'worker style' reforms.