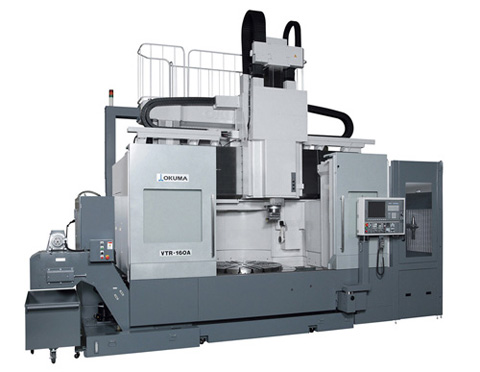

- Okuma launches the VTR-160A double-column turning center

Class-best machining capacity, class-smallest thermal deformation - 21 Jul 2009

In today's world, environmental protection and economic stimulation have become major issues. This has given rise to demand for more highly efficient, environmentally-friendly production equipment in industrial fields related to mass transit development and energy efficiency. To meet these needs, Okuma has developed the VTR-A Series of large vertical turning centers with double-column structures.

The VTR-A Series is based on our highly rigid, highly accurate, and highly acclaimed double-column machining centers. Large diameter cylindrical roller bearings and thrust bearings are used in the turning spindle (table) for stable support of heavy workpieces, while the milling spindle is an integral motor/spindle in a square 250 mm highly rigid ram structure. That provides for low vibration and highly accurate spindle rotations.

Machining dimensional changes over time from thermal deformation are also minimized with Okuma's unique Thermo-Friendly Concept.

High machining capacity inherited from Okuma's double-column machining centers

Turning OD turning: 10 mm (0.0155 in.

(0.0155 in. ) [S45C material with VTR-160A]

) [S45C material with VTR-160A]

Ram protrusion: 600 mm (23.62 in.)

Milling Drilling: 60 mm (ø2.36 in.)

60 mm (ø2.36 in.)

Tapping: M36

Outstanding, stable accuracy with use of Thermo-Friendly Concept

Thermal deformation over time: less than 20 µm (0.0008 in.) (X-axis direction)

(VTR-160A: 8°C room temperature change in 8 hours)

VTR-160A

Double-Column Turning Center

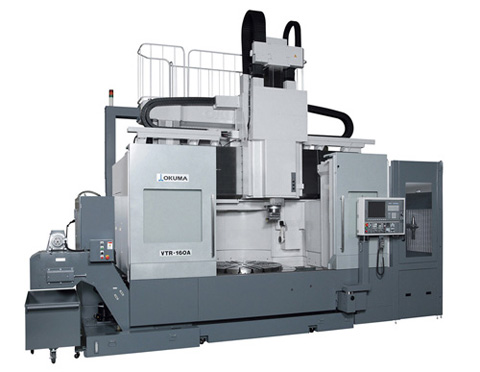

The VTR-A Series is based on our highly rigid, highly accurate, and highly acclaimed double-column machining centers. Large diameter cylindrical roller bearings and thrust bearings are used in the turning spindle (table) for stable support of heavy workpieces, while the milling spindle is an integral motor/spindle in a square 250 mm highly rigid ram structure. That provides for low vibration and highly accurate spindle rotations.

Machining dimensional changes over time from thermal deformation are also minimized with Okuma's unique Thermo-Friendly Concept.

High machining capacity inherited from Okuma's double-column machining centers

Turning OD turning: 10 mm

(0.0155 in.

(0.0155 in. ) [S45C material with VTR-160A]

) [S45C material with VTR-160A]Ram protrusion: 600 mm (23.62 in.)

Milling Drilling:

60 mm (ø2.36 in.)

60 mm (ø2.36 in.)Tapping: M36

Outstanding, stable accuracy with use of Thermo-Friendly Concept

Thermal deformation over time: less than 20 µm (0.0008 in.) (X-axis direction)

(VTR-160A: 8°C room temperature change in 8 hours)

VTR-160A

Double-Column Turning Center