Case Studies

Aiming to make a leap forward

through technical innovation,

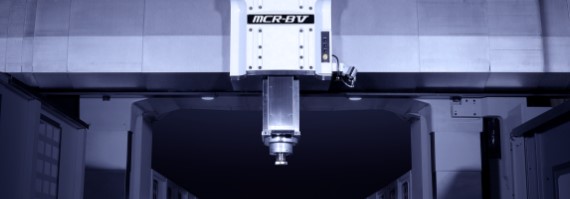

AAP selected Okuma's MCR-A5CⅡ

PT. ADIPERKASA ANUGRAH PRATAMA

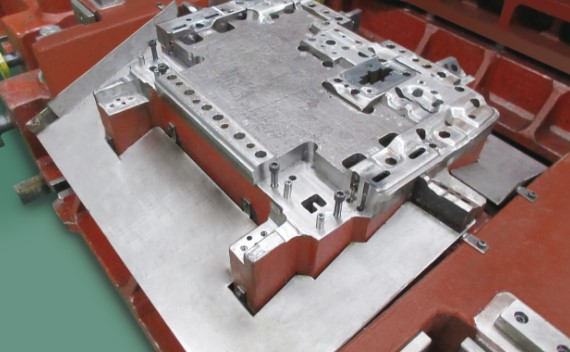

Located on the western side of Jakarta, PT. Adiperkasa Anugrah Pratama (AAP) was established in 2008 as a manufacturer of propane gas cylinders. AAP's customers include Japanese manufacturers of gas equipment, home appliances, and automobiles. In particular, it has established a reputation for its ability to respond to quality, delivery date, and cost requirements for molds and press dies, which affect the quality of end products.

From CNC lathes to cutting-edge double-column machining centers,

Okuma's machines have supported the breakthroughs of AAP since the early days after it was established

AAP introduced two units of the LCS-15, Okuma's compact CNC lathe, in its machining section at the time of its establishment. Regarding the reason for introducing them, Mr. Hans Honggo, President and CEO of AAP, said, "I had known of Okuma for long time because it is a well-known brand in the industry. Lathes manufactured by Okuma are useful because they can handle heavy-duty cutting even though they are compact."

Then, in 2015, AAP introduced an MCR-A5CⅡ double-column machining center (5-face machining) for press die machining of inner frames for cars. This machine was developed mainly for high-accuracy and high-production machining of large parts based on Okuma's unique double-column structure, which provides high rigidity. Its machining accuracy is stable even with temperature changes in the environment (Thermo-Friendly Concept). In addition, the auto tool changer (ATC) and auto attachment head changer (AAC) enable continuous machining to increase productivity. Demonstrating his confidence in the machine, Mr. Hans Honggo stated, "We are extremely pleased, as not only the machining accuracy but also the rigidity and durability are higher than we expected."

Customer Information

PT. ADIPERKASA ANUGRAH PRATAMA

- World Headquarters / Plants

- Jl. Pajajaran No.10,

Desa Jatiuwung Tangerang 15137, Indonesia

- Established

- 2008

- President and CEO

- Mr. HANS HONGGO

- Employees

- 500

- Phone

- 62-21-5917223