Made in Japan machine tools are regarded throughout the world as synonymous with high quality.

Okuma has been Japan's No. 1 in sales since the company was founded in 1898.

Okuma continues to be supported as a top brand in Japan

because we continue to refine our product quality backed by advanced technology.

Careful selection of high-quality castings and the creation of a strong internal structure that requires significant time for forging leads to high load resistance.

Diagonal rib structure

Thermo-Friendly Concept

Cumulative shipments: 60,000 units

Applicable Okuma products: 120 models

Machine design and highly accurate thermo deformation control technology that responds to temperature changes caused by machining, etc. in a straightforward manner.

Achieving highly accurate machining over long runs regardless of changes in ambient temperature.

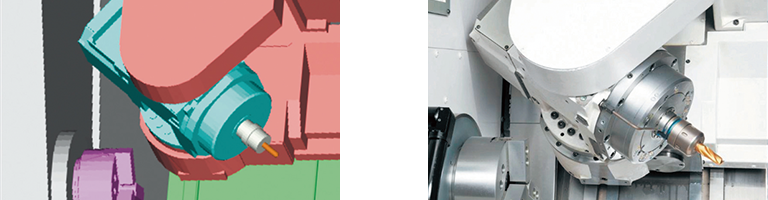

Collision Avoidance System

Real-time simulation using 3D data of machine structures.

Prevents collisions and drastically reduces cycle time.

lnterference check precedes actual movement

Machining Navi

Detects and suppresses chatter vibration during machining and calculates optimal machining.

Providing machining technologies that supports high accuracy and productivity which anyone can use.

Offering machining solutions only possible through the use of a CNC developed by Okuma.

Based on actual shop conditions, evaluations with continuous 2,000-hour long durability tests at maximum spindle speed are performed to also assure extended product life. Only successfully tested machines are approved for sale as Okuma products.

Representing Okuma's best-selling machine

1-Saddle CNC Lathe

More than 18,000 units in our best-selling machine LB EX series

One machine for high-quality to heavy-duty die/mold applications

Vertical Machining Centers

More than 11,000 units in our best-selling machine MB-V series

Okuma's DCMC Series ranked No. 1 in Japan

Double-Column Machining Centers

More than 10,000 DCMC Series machines have been sold since 1964.

Highly accurate and powerful machining that changed the conventional wisdom of 5-axis machining

5-Axis Vertical Machining Centers

3-axis machine equivalent high machining capacities

Highest level milling and turning efficiency

Intelligent Multitasking Machines

Wide range of applications—irregular workpieces also possible

As a comprehensive machine tool manufacturer, see the variety of Okuma products boasting a lineup of more than 100 models

from the product brochures available.

The download page will open in a new browser window.

The processing and assembly of each main spindle, said to serve as the "heart" of every machine, are performed in a room which is kept at a constant temperature.

Since the temperature is kept at 23°C with an allowable variance of ±1°C and there is no temperature change between processing and assembly, dimensional accuracy is stabilized, making high-precision processing and assembly possible in a short amount of time.

In addition, since the air pressure in the spindle unit assembly area is increased, high quality is maintained by preventing the intrusion of dust.

* A round bar with a diameter of 100 mm expands by approximately 1 micrometer (0.001 mm) for each degree (°C) the temperature rises.

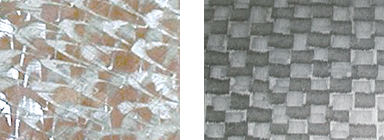

After years of hard training, the skills of master craftsmen continue to be passed on.

Japanese style hand/hip scraping "Kisage" results in beautifully finished flat and curved surfaces achieving high accuracies of 1 and 2 µm that exceed automated scraping systems, and the mated scraped surfaces prevent machined workpiece deformation while supporting their accuracy requirements.

For moving components, oil film applications reduce slide resistance, and produce delicate, beautiful patterns reminiscent of traditional Japanese designs appearing on the entire finished surface.

Outstanding craftsmanship is poured into each Okuma product, leading to highly accurate components, assemblies, and the best finished machine tool possible.

Okuma started manufacturing and selling noodle machines in 1898.

Possessing an enormous passion for improving quality, our founder Eiichi Okuma had at the time developed a revolutionary high-precision lathe in-house required for making 0.05 mm wide parts for the purpose of improving the main parts of the company's noodle machines.

This technology would become the basis for entering the machine tool field, transforming Okuma into an integrated machine tool manufacturer.

In 1963, Okuma developed the OSP, an NC controller with absolute position feedback.

By developing both the NC machine and controller, Okuma was able to bring products that accurately supported user needs to the market.

As a manufacturing professional, we always listen to customer feedback

and take on the challenge of creating new value through innovation and by providing

a level of comprehensive support that exceeds expectations.

Okuma strives to become a company that lives up to customer expectations and inspires them.

We open the future possibilities of manufacturing.

As a leading machine tool company, learn more from the Okuma brochures which describe our wide range of products, from highly accurate and rigid CNC lathes, machining centers, and multitasking machines to the Okuma CNC controls (OSP).

The download page will open in a new browser window.