Okuma 120th anniversary commemorative video

We want everyone to see the passion for monozukuri of this company called Okuma.

With that in mind, please watch this video made for our 120-year anniversary.

Creating what does not exist.

Okuma's 120 years.

Okuma's 120 years are a history of new challenges.

Here we tell Okuma's history of constantly creating the things that people want.

-

1898~

Okuma's foundational years

Learn More > -

1898

Eiichi Okuma founded the Okuma Noodle Machine Co. in Nagoya and began to manufacture and sell noodle-making machines. In the first year, he made and sold 20 machines.

Noodle-making machine 1904

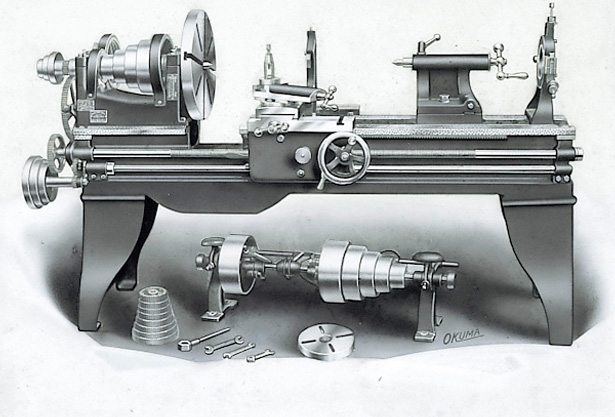

The company began to manufacture machine tools.1914

Eiichi Okuma obtained his first patent for a machine tool with the "Okuma automatic gear cutting lathe" (patent no. 25829).1918

The company name was changed to Okuma Machinery Works Ltd.

Sales of OS center lathes started. With a tremendous market response, it became a best-selling and long-selling lathe with a total of 2,000 units shipped over 25 years.

OS engine lathe 1930

The mayor of Nagoya approved the "Chukyo Detroit Plan," and Okuma participated in the manufacture of a car built in Japan, the "Atsuta-Go." Okuma was entrusted with building an 8-cylinder engine.

Atsuta Shrine, from which the name for the "Atsuta-Go" was taken 1937

Okuma became No. 1 in domestic production of machine tools.1953

Manufacture of DRA radial drilling machines started. Okuma became the No.1 producer (volume) of radial drilling machines in Japan.1958

Manufacture of DRA-J drilling and boring machines started. Together with the DRA, the Okuma name became synonymous with industrial drilling machines.

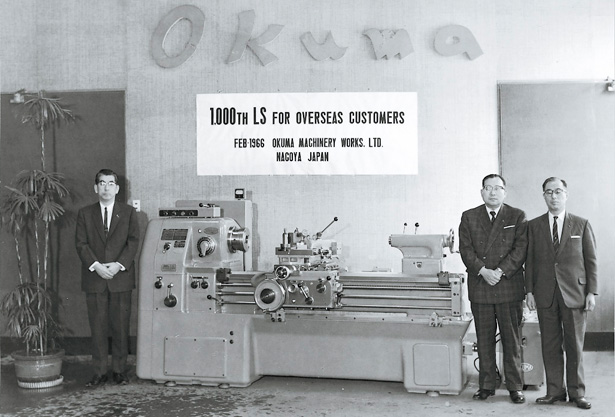

Manufacture of LS high-speed engine lathes started. A total of 30,000 units of this small, "Type LS Productive" lathe were sold. With sales in 40 countries, it became Okuma's biggest hit product.

Okuma commemorates export of 1,000 LS lathes

-

1961~

NC control development

Learn More > -

1961

Research started on the OSP numerical control (NC) toward replacing mechanical movements with digital control.1963

The OSP III NC with absolute position feedback was developed. Okuma embarked on a history as Your Source for Machine & Control.

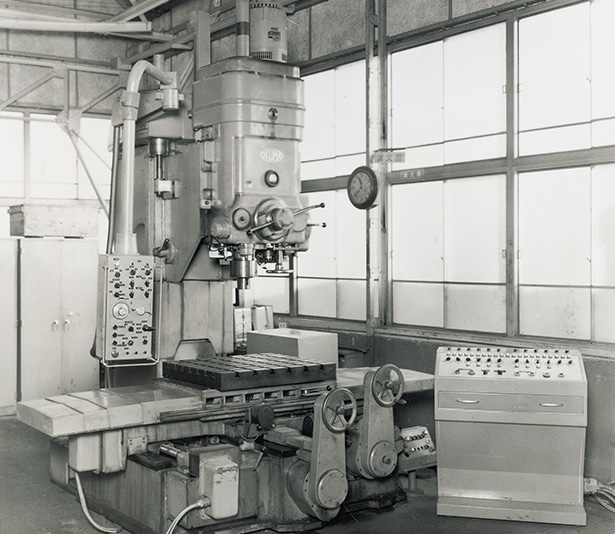

The first OSP III, mounted on the DVJ vertical boring machine 1966

Manufacture of the MDB double column machine started. For milling, drilling, and boring applications on a single machine, two types (NC or manual) were offered.1967

Manufacture of the LA40-N NC lathe started. Okuma's first mass produced NC lathe. It was a highly rigid machine that used a slanted bed to achieve high accuracies more easily.

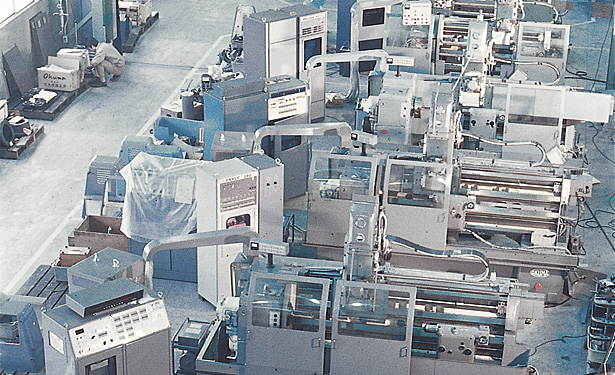

LA40-N assembly line 1968

Manufacture of MCD double column machining centers started—Okuma's first double-column machining center.1970

An assembly factory was completed at the current world headquarters plant in Oguchi (central Japan). This completed Okuma's manufacturing and sales management system for NC lathes.

The NC Center was opened with demonstraction and educational facilities for NC machines in north Nagoya, which at the time served as company headquarters.1972

Okuma's OSP 2000 CNC (computerized NC), which led the world as a practical CNC with a built-in computer, was completed. Okuma's first CNC was mounted on the LA45-N, other lathes, and the MDB-N boring machine. Production continued for more than 7 years and it became a best seller.

OSP2000 CNC 1976

The OSP 300 CNCs with microprocessors was completed. It played a key role in the development of simultaneous 4-axis CNC lathes and became a driving force in the spread of CNC machine tools.1980

Manufacture of the MC-5/5H horizontal machining centers started. It was Okuma's entry into the small and medium-sized applications market.

-

1981~

Spread and expansion of CNC machines

Learn More > -

1981

The IGF (Interactive Graphic Function) was launched; a conversational programming tool that allowed users to create part programs by following quick-and-easy interactive user graphics--which also attracted much attention.1982

Manufacture of the LB15 CNC lathe started; featuring compactness, ease of use, and powerful cutting. It became a hit product, recording sales of more than 15,000 units over the 10 years after its launch.

LB15 CNC lathe 1983

Company headquarters moved from north Nagoya to Oguchi in 1982. After the move, Okuma's largest in-house trade show, the 1st Okuma Machine Fair, was held.1988

K1, the first factory at the Kani Plant was completed in Kani City.1989

One-Touch IGF, an interactive NC with that automatically determines all the machining processes, was developed. The number of input strokes reduced by 60% compared to the previous version. Input time was also greatly reduced.1991

The company name was changed to Okuma Corporation. At the same time, the corporate logo in use today was launched.

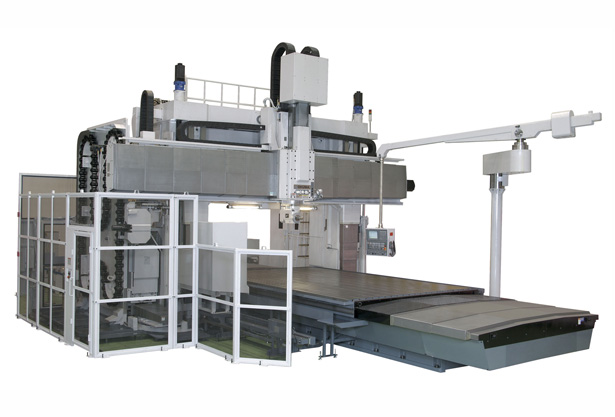

Manufacture of the MCR-BII double-column machining center for 5-sided applications started. Machining of all kinds of parts became possible with a rich array of attachment heads, greatly increasing productivity in the machining of large workpieces.

MCR-BⅡ35E

-

2000~

Toward new value creation

Learn More > -

2000

IT PLAZA, a new model for manufacturing that utilizes IT, was launched.2001

The Thermo-Friendly Concept was developed; an Okuma Intelligent Technology that accurately controls thermal deformation.

The MB-46V vertical machining center is Okuma's first machine equipped with the Thermo-Friendly concept 2004

Okuma developed its second Intelligent Technology, the Collision Avoidance System, which prevents collisions so that operators can concentrate on machining.

The MULTUS B300 multitasking machine, the first machine to be equipped with the Collision Avoidance System 2008

Machining Navi, another Okuma Intelligent Technology was developed; with a cutting-conditions search function that raises productivity.2013

Dream Site 1 (DS1), a factory for self-contained start-to-finish production, from parts machining to assembly, was completed at the headquarters plant.2014

"OSP suite," a next-generation intelligent CNC was developed. It comes with "suite apps" for better efficiency in each production process and "suite operation," which enables changes to the operation screens to match individual operator preferences.2015

The "OPEN POSSIBILITIES" brand message was launched.

2016

The LASER EX Series was developed. These next-generation super multitasking machines, with laser machining technology, are the ultimate machines for process-intensive machining from materials to finished product on a single machine.

The MULTUS U3000 LASER EX super multitasking machine

With IoT, I hope to make Okuma plants places where highly efficient production activities and quick maintenance and improvements can be done by anyone.

Production Engineering Department

I want to develop machines and technology that will raise the Okuma brand further and inspire customers around the world.

R&D Department

I want to be close to customers and propose the best application for them, deepening ties and increasing the number of people who look to Okuma first!

Solutions R&D Center

I want to expand possibilities, from the development of personnel to Okuma monozukuri, and contribute to productivity improvements on customer shop floors.

Human Resources Department

Through trade show support and Web marketing, I hope to spread Okuma's "trustworthy monozukuri" to customers worldwide.

Marketing Office

With friendly competition and teamwork in the workplace, I want to deliver the highest quality products to customers worldwide.

Kani Production Department

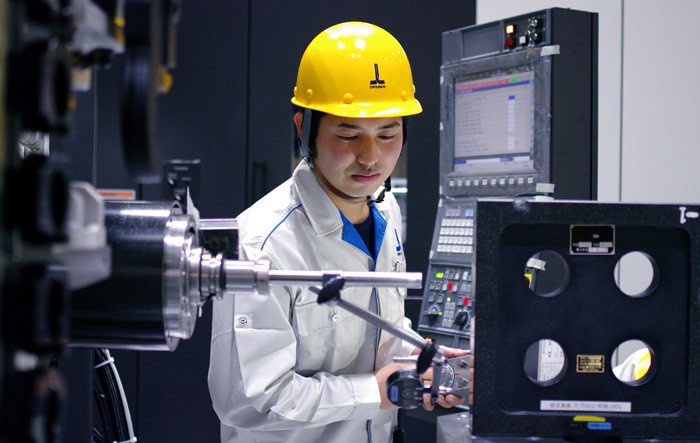

With control technology that will not compromise a single micron, I want to meet the needs of the customers who support Okuma.

Hardware Engineering Department

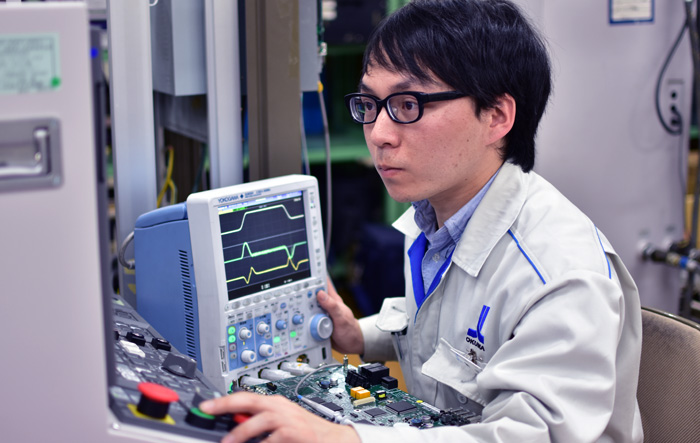

I want to provide high value-added machine control software that is easy to use for everyone, and contribute to the manufacturing activities of customers worldwide.

Software Engineering Department

I aim to provide the very best service that earns customer trust with quick, thorough, and reliable repairs in cases of machine malfunction.

Service Department

We want to be the bridge between customers and Okuma by listening carefully to the issues and troubles faced by customers.

Sales & Marketing Division

I look forward to 30 years with Okuma so that I can become an expert in the industry and better support our customers.

Okuma America Corporation

I want to be the kind of engineer who can discover customers' true intent wherever they are in the world and deliver satisfaction.

Sales Engineering

I want to develop an easy-to-use OSP that expands customer possibilities, taking advantage of Okuma's strengths as "Your Single Source for M-E-I-K (Mechanics - Electronics - IT - Knowledge)."

FA R&D Department

I would like to elevate the Okuma brand image by planning and realizing full turnkey solutions for European leading industries.

Okuma Europe GmbH

Being positive and never giving up—I want to share the Okuma spirit with every one of our customers.

Okuma Machine Tool (Shanghai) Corporation

From Thailand, land of smiles, to the world—I want to expand Okuma's role with customers together with our smiling OTT staff.

Okuma Techno (Thailand) Ltd