PRODUCTS

- Stable machining of large workpieces

- Stable machining achieved even with difficult-to-chuck thin, large-diameter workpieces and unbalanced, odd-shaped components.

-

Pulley -

Bearing -

Valve body

-

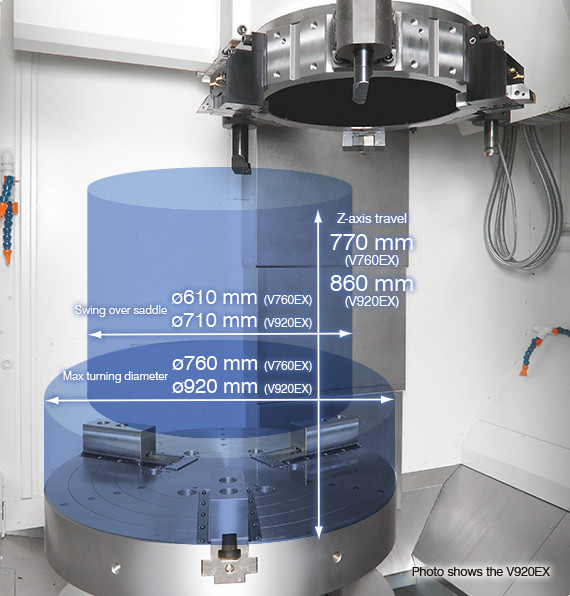

- Large machining area can accommodate a wide range of applications

- Large machining area achieved with small footprint. Sufficient space (maximum swing: ø800 mm/V760EX, ø1,000 mm/V920EX) for chucking of odd-shaped workpieces is also provided, meeting a wide range of customer machining needs.

-

-

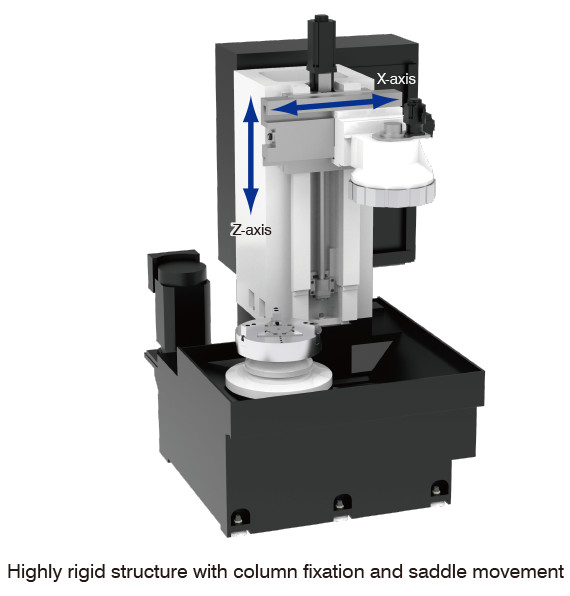

- Advanced, highly rigid construction enables powerful and very accurate machining

- A rock-solid rectangular column is firmly secured to a rigid base with excellent damping performance. Minimal tool-to-column guideway distance assures the rigidity needed to withstand heavy-duty cutting loads. Moreover, the box ways for the X and Y axes help to achieve heavy-duty cutting of big components at high accuracies.

-

-

- The features of vertical lathes provide for highly accurate, stable machining

- Since the adhesive weight of a workpiece helps clamp it to the chuck's reference surface.

This prevents workpiece warp, and accommodates thin, large-diameter, or heavy workpieces.

With fixtures for odd-shaped components, manual part load/unload (without holding the part in place) is also easy.

-

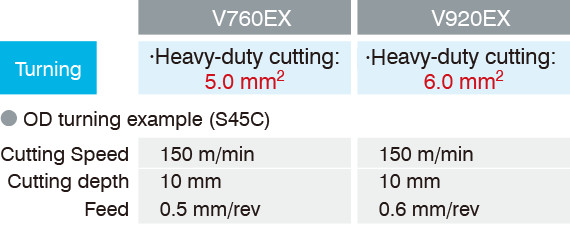

- Machining capacity (actual data)

-

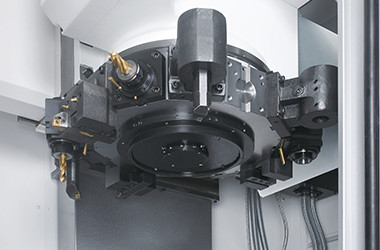

- Process-intensive machining with powerful milling

- More powerful, can use greater number of tools

-

V760EX Turning, drilling, end milling all done on a single machine to accommodate a wide range of applications. A much more powerful milling tool spindle than on previous machines enables more powerful cutting and a wider range of process-intensive machining. The turret minimizes interference with neighboring tools so that millling tools can be attached in all 12 locations.

Applications from turning to milling can be done with a single chucking, reducing the work in progress storage space and between process waiting times. Chucking error during workpiece installation can also be eliminated for higher machining accuracies.

- Innovative shop floor productivity in many types of production

- High productivity with 2 roles by 1 machine (2SP-V760EX, 2SP-V920EX)

-

The 2-spindle spec 2SP-V760EX, 2SP-V920EX combines a standard R (right) machine and reverse structure L (left) machine and is operated with a single controller.

This gives the maximum productivity with the minimum floor space by shortening lead times and cutting down on intermediate work in progress.

The separated right-left structure also enables stable machining that is unaffected by the machining vibration of the other spindle.- Compact lines that minimize robot travel can be built.

Highlighted Specs

| Item | Unit | V760EX [2SP-V760EX] |

V920EX [2SP-V920EX] |

|---|---|---|---|

| Applicable chuck sizes | in | 15, 18, 21, 24 | 24, 28, 32, 36 |

| Max turning dia | ømm (øin) | 760 (29.92) | 920 (36.22) |

| Max work length (height) | mm (in) | 770 (30.31) | 860 (33.86) |

| Spindle speed | min-1 | 2,000 | 1,250 |

| Turret | V12 | V12 | |

| Motor | kW (hp) | 30/22 (30 min/cont) (40/30) | 30/22 (30 min/cont) (40/30) |

| Machine size (W × D × H) |

mm (in) | 1,842 × 2,732 × 3,489 (72.52 × 107.56 × 137.36) [3,680 × 2,732 × 3,489] (144.88 × 107.56 × 137.36) |

2,252 × 2,845 × 3,693 (88.66 × 112.01 × 145.39) [4,500 × 2,845 × 3,693] (177.17 × 112.01 × 145.39) |

| Spec extension | M | M, ATC * | |

| CNC | OSP / FANUC | OSP / FANUC |

M: Milling

* ATC can be selected in V920EX