- HOME

- Technology & Solutions Premium Solutions

- Gear Machining Package

Technology & Solutions Premium Solutions

Easy multitasking for gears

Highly accurate gear cutting achieved with multitasking machines and 5-axis machining centers.

Output programs just by entering the gear data.

- Production floor issues

- Gear cutting requires expensive dedicated machines

-

- • Gears that require multitasking operations are on the rise.

- • Subcontractors with special-purpose equipment being relied on.

- • Workpiece changes for dedicated machines cause setup changes with many work-hours and high costs.

- • Skilled part programming required for gear cutting.

- User benefits

- Gear cutting easy with multitasking machines

-

- • Expensive special-purpose machines not required for gear cutting.

- • Whole part done-in-one setup.

- • Auto gear programming from tool spec inputs.

- • Process-intensive application reduces setup changes and machining wait times.

Easy output of gear part programs

Different gear types made it difficult to create programs because tool cutting conditions, paths (number of passes, directions), angles, and positions were also different.

Okuma's Gear Machining Package solves these problems.

-

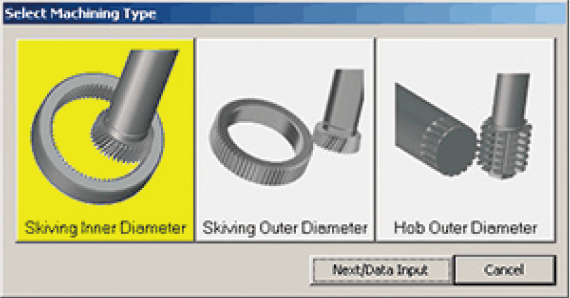

- STEP1

- Gear types

■ Select from three

Skiving ID / Skiving OD / Hob OD

-

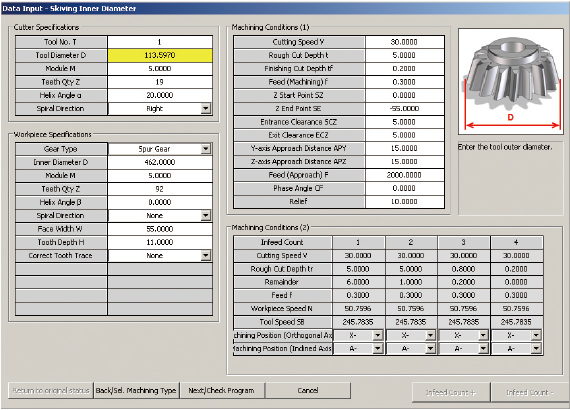

- STEP2

- Input cutting conditions

■ Input tool type, gear specs, and cutting conditions

-

- STEP3

- Auto programming and execute

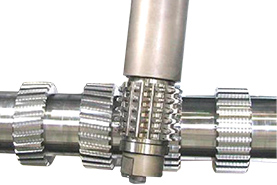

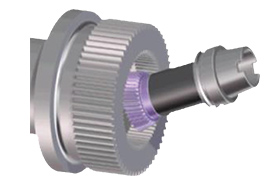

Skiving

With precisely synchronized rotation of the workpiece and tool spindles, skiving is possible with a multitasking machine or a 5-axis machining center.

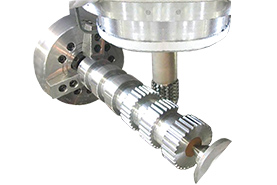

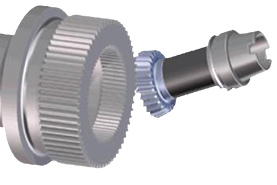

Hobbing

Workpiece OD hobbing requiring special fixturing is possible with a multitasking machine.